Composite containing polyhydroxybutyrate copolymer and polylactic acid used for foaming material

A technology of polyhydroxybutyrate and composition, applied in the polymer field, can solve the problems affecting the normal collection and production output of products, high cost, slow crystallization rate, etc., and achieve easy operation and industrialization, popularization and popularization of production, processing and molding methods. Simple, yield-efficient results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation of embodiment foam material

[0030] The foaming agent formula is as follows:

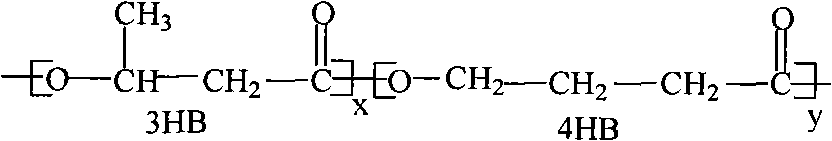

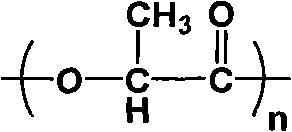

[0031] In parts by mass, and based on the main component polyhydroxybutyrate copolymer P (3HB-co-4HB) (100 parts by mass), the proportions of each component are as follows:

[0032] Polyhydroxybutyrate copolymer P (3HB-co-4HB) 100 parts

[0033] Polylactic acid (PLA) 100-700 parts

[0034] Foaming agent: 0.2~1.5 parts

[0035] Organic and / or inorganic additives 0-60 parts

[0036] Other additives: 0~5 parts

[0037] Processing method: Blend all raw materials, extrude and granulate. Then extrude the foamed sheet, the temperature is controlled at 140°C-180°C, the screw speed is 20-150 rpm, and water-cooled. The foamed sheet is then blistered on the blister machine to form a finished product.

Embodiment 1

[0039] In terms of parts by mass, 100 parts of P (3HB-co-5mol% 4HB), 700 parts of PLA, and 1.5 parts of AC; all raw materials are blended and extruded to granulate; then extruded foam sheets; products.

Embodiment 2

[0041] Select 100 parts of P (3HB-co-95mol% 4HB) in parts by mass, 400 parts of PLA, 1.0 part of AC, and 0.2 part of calcium stearate; blend all raw materials and extrude granulation; then extrude foam sheet Material; then plastic molding into products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com