Method for preparing multi-level structural microarray by laser direct-writing technology

A technology of laser direct writing and microarray, applied in optomechanical equipment, microlithography exposure equipment, optics, etc. Focus problem, the effect of fast processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

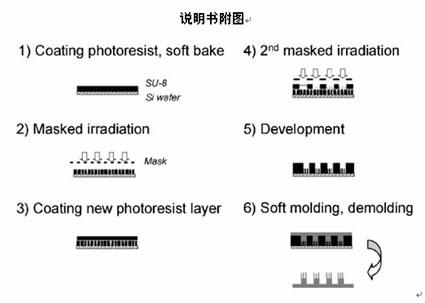

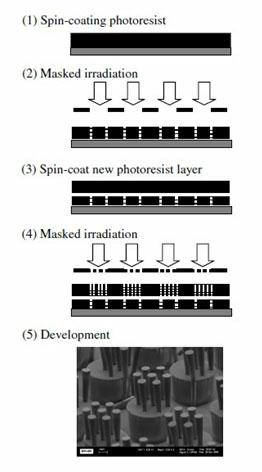

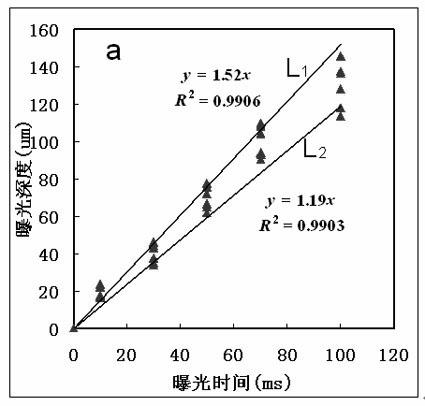

[0034] according to Figure 6 The method shown, "top-down" to prepare the specific implementation steps of the secondary structure (first-level structure size: diameter 200 μm, spacing 500 μm, height 120 μm; second-level structure size: diameter 20 μm, spacing 40 μm, height 40 μm) For: 1. Hot roll coating. Using 650RS coil laminating machine, the temperature is 110°C, and the laminating speed is 1m / min. The film is rolled and laminated on the substrate. The single-layer film thickness is 40μm and can be laminated multiple times as needed. This implementation is one layer of lamination. 2. Fully exposed, as a soft base. Fully expose the laminated film to ultraviolet light for 5 minutes. At this time, the color of the photoresist changes from light blue to dark blue, forming a soft base. 3. Second coat. The film is pasted on the soft substrate by hot rolling, and can be laminated multiple times as required. In this case, 4 layers of film are implemented. 4. Expose piece by p...

Embodiment 2

[0036] according to Figure 6 The method shown, "top-down" to prepare the specific implementation steps of the secondary structure (first-level structure size: diameter 200 μm, spacing 500 μm, height 152 μm; second-level structure size: diameter 3 μm, spacing 8 μm, height 8 μm) For: 1. Hot roll coating. Using 650RS coil laminating machine, the temperature is 110°C, and the laminating speed is 1m / min. The film is rolled and laminated on the substrate. The single-layer film thickness is 40μm and can be laminated multiple times as needed. This implementation is one layer of lamination. 2. Fully exposed, as a soft base. Fully expose the laminated film to ultraviolet light for 5 minutes. At this time, the color of the photoresist changes from light blue to dark blue, forming a soft base. 3. Second coat. The film is pasted on the soft substrate by hot rolling, and can be laminated multiple times as required. In this case, 4 layers of film are implemented. 4. Expose piece by piec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com