Method for implementing base region window of silicon germanium heterojunction transistor

A heterojunction transistor and base technology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of discontinuous metal silicide, increased resistance of the outer base, and insufficient insulation. Achieve the effect of eliminating sidewall residues, reducing base resistance, and reducing defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

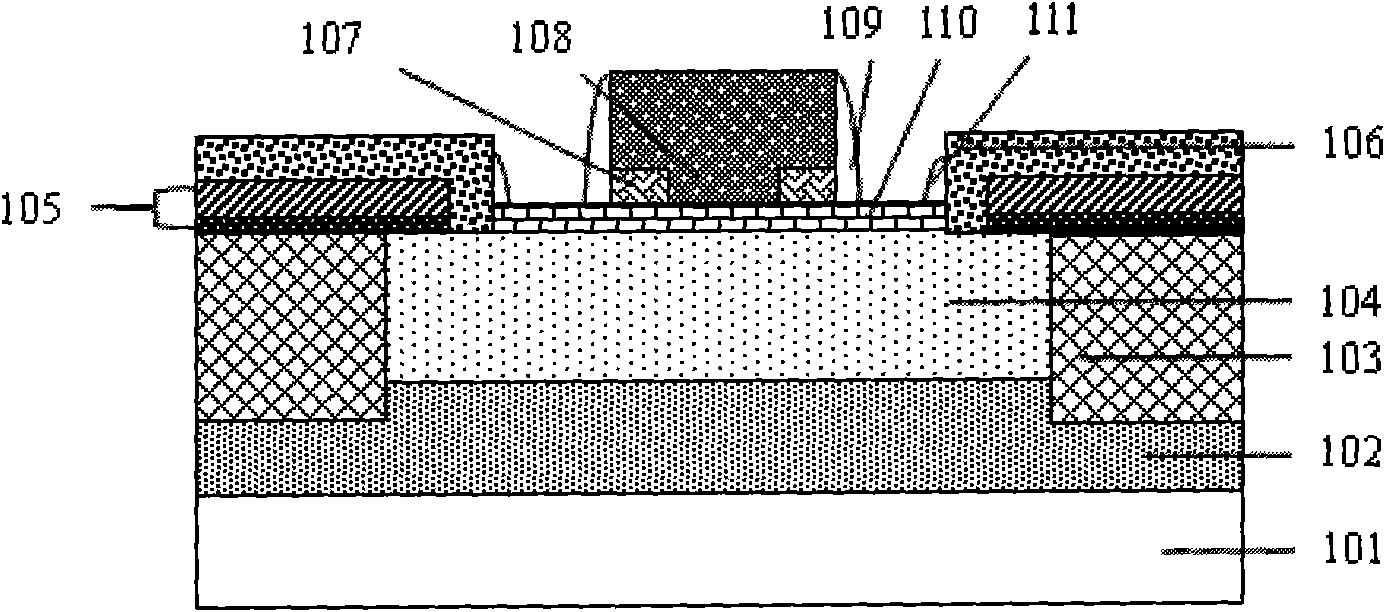

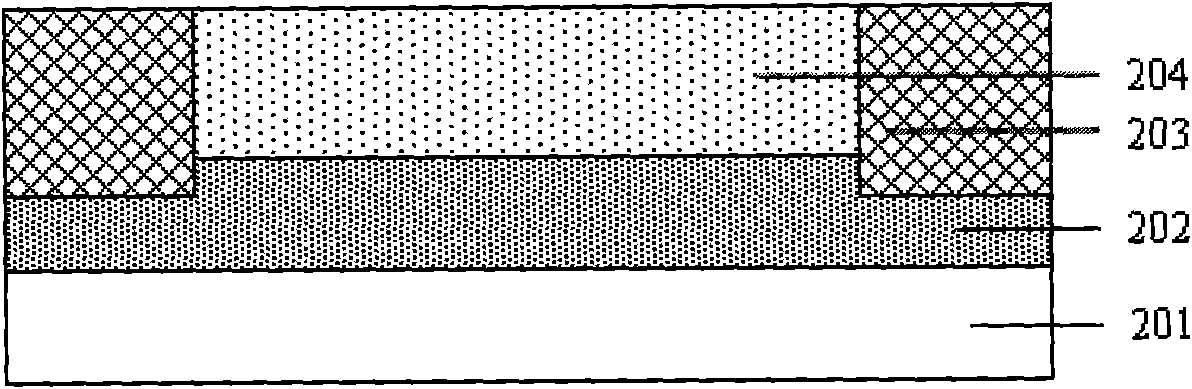

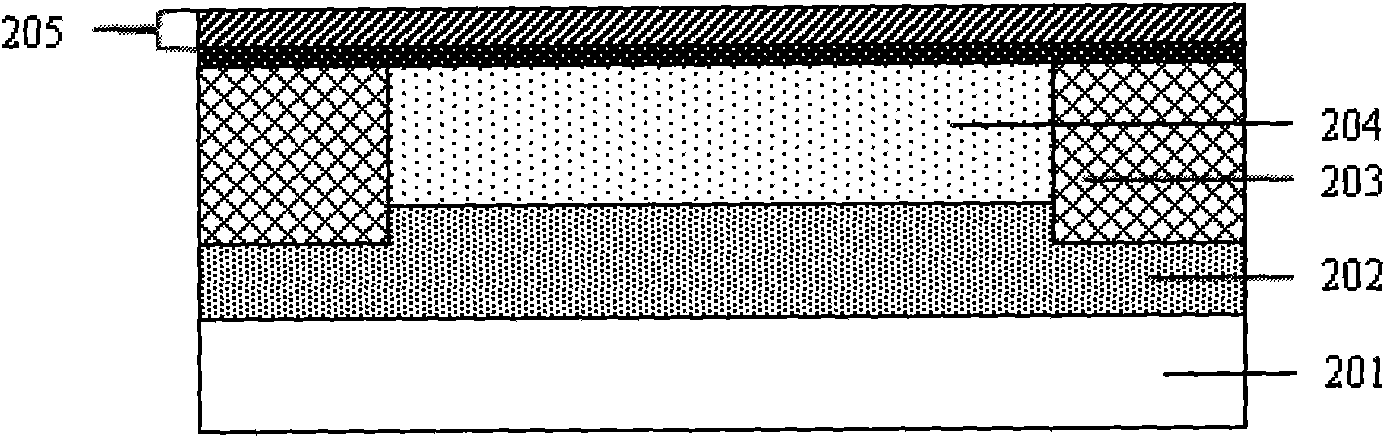

[0020] The method for realizing the base region window of the silicon-germanium heterojunction transistor described in the present invention is to deposit a layer of dielectric film layer after the dielectric film is partially opened and before the oxide film is removed, and use the dielectric film layer to form a step in the base region window interface. A D-shaped side wall is formed; at the same time, using the protection of the D-shaped side wall, the remaining oxide film in the window of the base region is removed by wet method, and the SiGe base region is epitaxially grown in a short time. The formation of the D-shaped sidewall makes the step of the window interface of the base area gradually changed. After SiGe epitaxy, the gradually changed step formed by the D-shaped sidewall remains, so that there is no insulator residue in the subsequent emitter polysilicon sidewall process. In this way, a continuous metal silicide is formed to reduce the resistance of the outer base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com