Method for enhancing luminous intensity of LED by electron beam irradiation

A technology of electron beam irradiation and luminous intensity, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of LED luminous intensity increase, carrier mobility decay, carrier lifetime decay, etc., to improve LED luminous intensity. The effect of luminous intensity, ease of operation, and increased probability of radiation recombination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

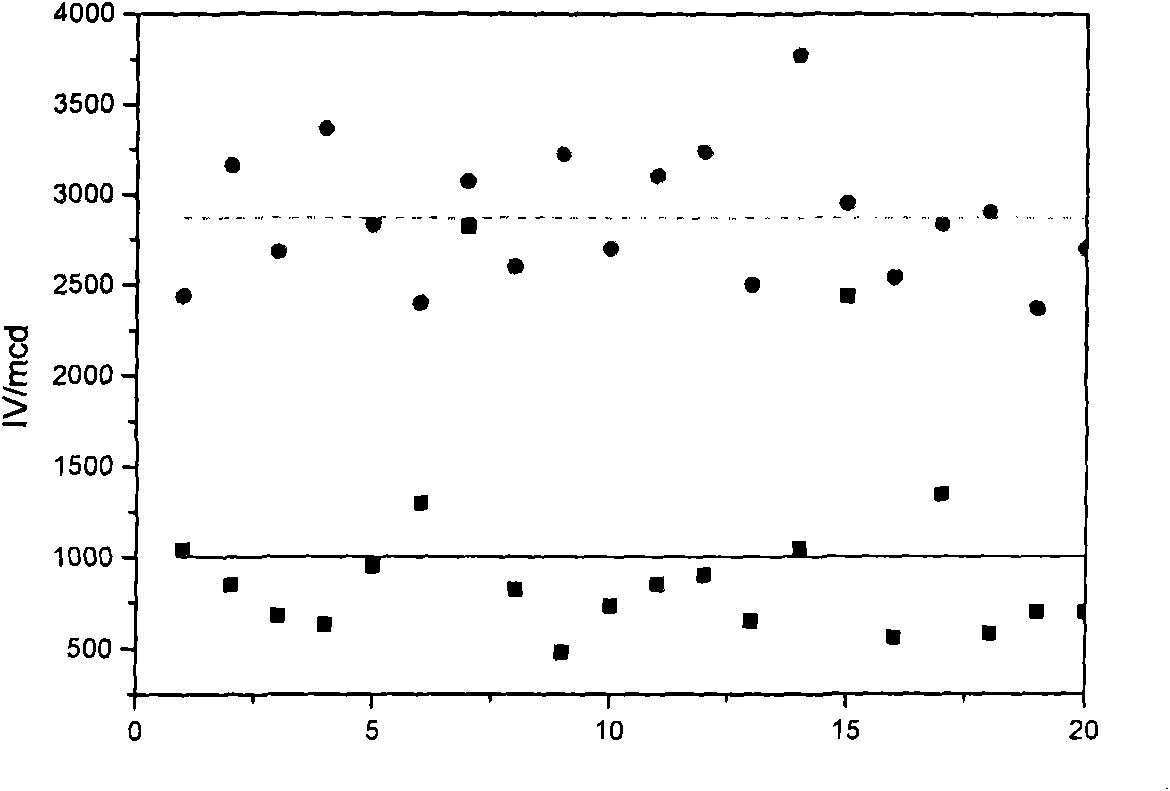

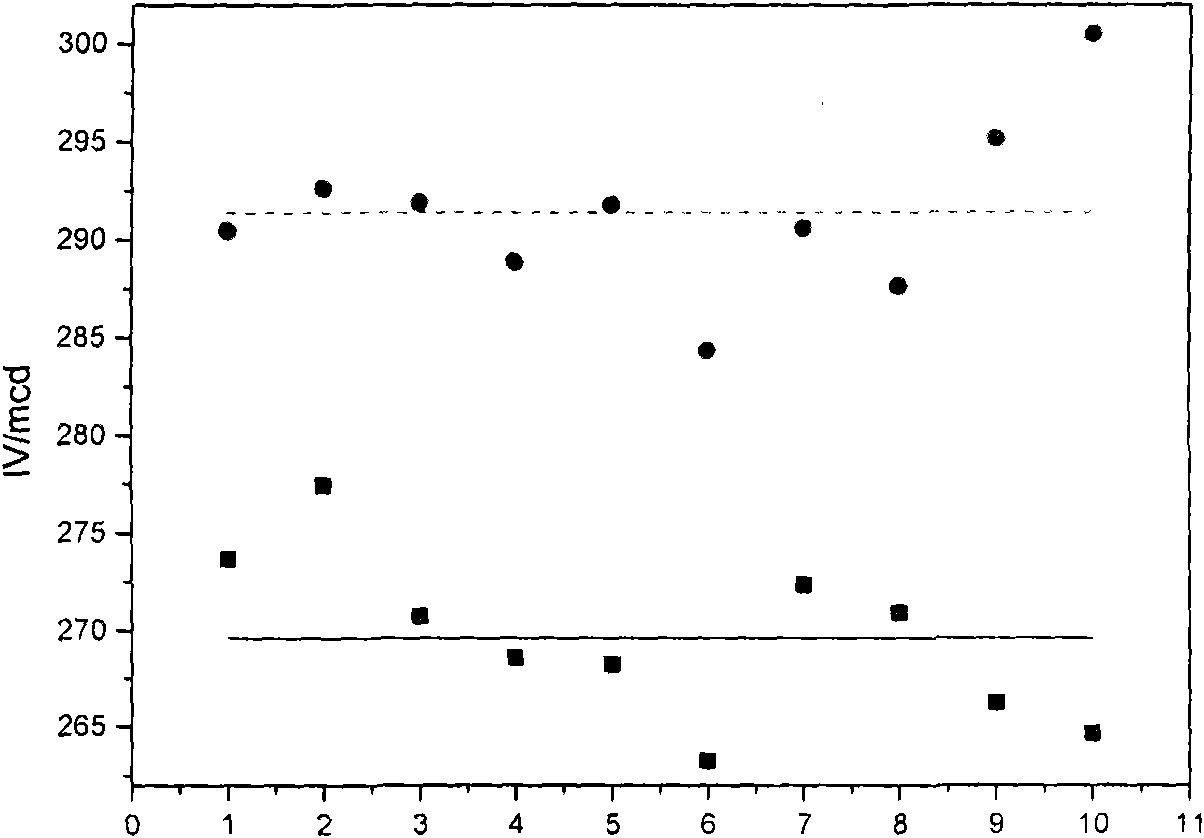

[0013] Embodiment 1: Place the AlGaInP-based low-power red LED chip under the GJ-15 type Dinamil electron accelerator, the radiated electron energy is 1MeV, the irradiation atmosphere is 1 standard atmospheric pressure, ordinary air atmosphere, and the electron beam irradiation dose is 10KGy, the irradiation time is 10S.

Embodiment 2

[0014] Embodiment 2: The GaN-based high-power blue LED chip is placed under the GJ-15 type denami electron accelerator, the radiated electron energy is 1.5 MeV, the irradiation atmosphere is 1 standard atmospheric pressure, ordinary air atmosphere, and the electron beam irradiation dose is 100KGy, the irradiation time is 30S.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com