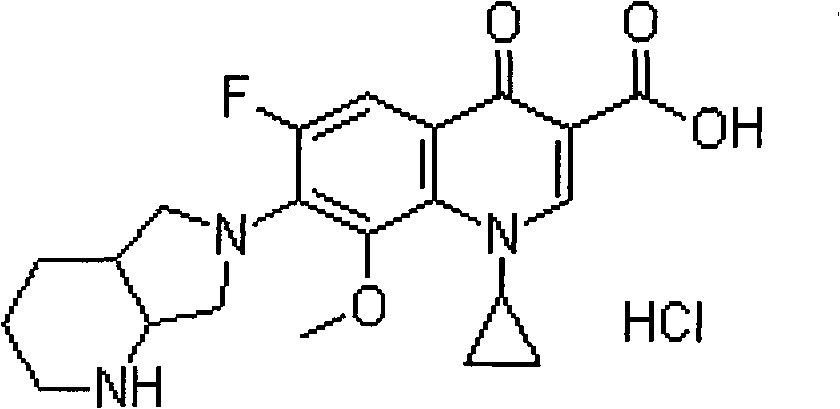

New moxifloxacin hydrochloride injection

A technology of moxifloxacin hydrochloride and injection, applied in the field of medicine, can solve the problems of poor operability, unqualified clarity, aggravated condensation reaction and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

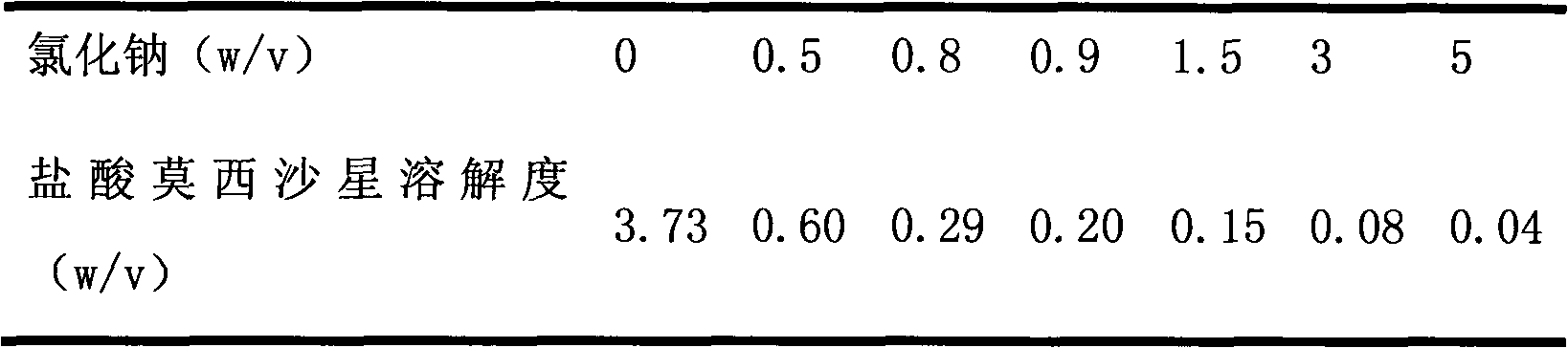

Problems solved by technology

Method used

Image

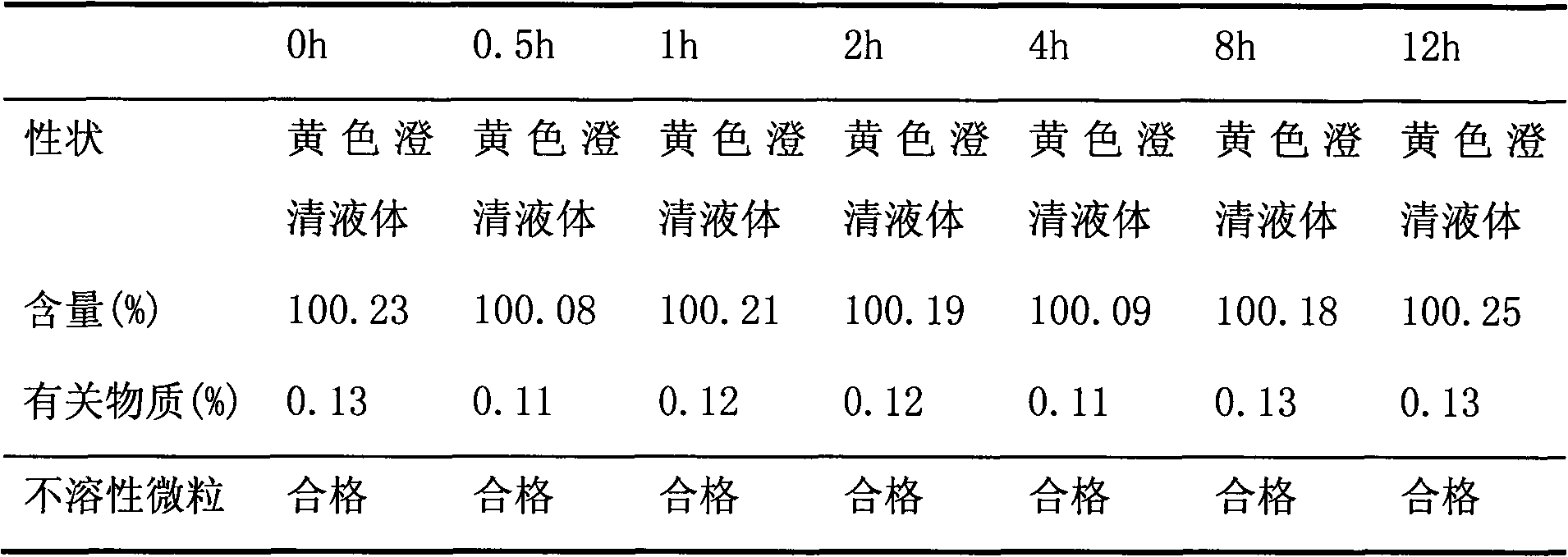

Examples

Embodiment 1

[0029] Example 1. Preparation of Moxifloxacin Hydrochloride Injection 1

[0030] Moxifloxacin Hydrochloride Injection (20ml: 400mg)

[0031] prescription:

[0032] Moxifloxacin hydrochloride: 0.4Kg (based on moxifloxacin)

[0033] Water for injection: 20L

[0034] Total preparation: 1000

[0035] Preparation Process:

[0036] (1) Wash and sterilize the ampoules required for production;

[0037] (2) 80% of the water for injection is kept at 50°C, then add moxifloxacin hydrochloride and stir to dissolve;

[0038] (3) Adjust the pH to 5.0 with 0.5 mol / l sodium hydroxide solution, add water for injection to the full amount, and stir evenly;

[0039] (4) Add 0.1% activated carbon for needles, stir for 15 minutes, filter and remove carbon;

[0040] (5) The medicinal solution is finely filtered through 0.45μm and 0.22μm membrane filters;

[0041] (6) Determine the intermediates and potting after passing the inspection;

[0042] (7) Steam sterilization at 121 degrees for 15 minutes;

[0043] (8) Leak de...

Embodiment 2

[0064] Example 2. Preparation of Moxifloxacin Hydrochloride Injection 2

[0065] Moxifloxacin Hydrochloride Injection (10ml: 200mg)

[0066] prescription:

[0067] Moxifloxacin hydrochloride: 0.2Kg (based on moxifloxacin)

[0068] Water for injection: 10L

[0069] Total preparation: 1000

[0070] Preparation Process:

[0071] (1) Clean and sterile the vials and rubber stoppers required for production;

[0072] (2) 80% of the water for injection is kept at 50°C, then add moxifloxacin hydrochloride and stir to dissolve;

[0073] (3) Adjust the pH to 5.5 with 0.5 mol / l sodium hydroxide solution, add water for injection to the full amount, and stir evenly;

[0074] (4) Add activated carbon for needles with a solution amount of 0.05%, stir for 20 minutes, filter and remove carbon;

[0075] (5) The medicinal solution is finely filtered through 0.45μm and 0.22μm membrane filters;

[0076] (6) Determine the intermediates and potting after passing the inspection;

[0077] (7) Steam sterilization at 115 ...

Embodiment 3

[0086] Example 3. Preparation of Moxifloxacin Hydrochloride Injection 3

[0087] Moxifloxacin Hydrochloride Injection (20ml: 400mg)

[0088] prescription:

[0089] Moxifloxacin Hydrochloride: 400g (based on Moxifloxacin)

[0090] Calcium edetate sodium: 50g

[0091] Water for injection: 20L

[0092] Total preparation: 1000

[0093] Preparation Process:

[0094] (1) Clean and sterile the vials and rubber stoppers required for production;

[0095] (2) 80% of the water for injection is kept at 50°C, and the raw and auxiliary materials are added and stirred to dissolve;

[0096] (3) Adjust the pH to 5.0 with 0.5 mol / l sodium hydroxide solution, add water for injection to the full amount, and stir evenly;

[0097] (4) Add activated carbon for needles with a dosage of 0.05%, stir for 15 minutes, filter and remove carbon;

[0098] (5) The medicinal solution is finely filtered through 0.45μm and 0.22μm membrane filters;

[0099] (6) The liquid medicine is sterilized through a 0.22μm filter membrane in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com