Varifocal lens of micro-fluid control liquid based on ionic liquid

An ionic liquid and liquid lens technology, which is applied to lenses, optics, instruments, etc., can solve the problems of increased thickness of the insulating layer, failure to work properly, breakdown of the insulating layer, etc., and achieve the effects of reduced driving voltage, easy fabrication, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

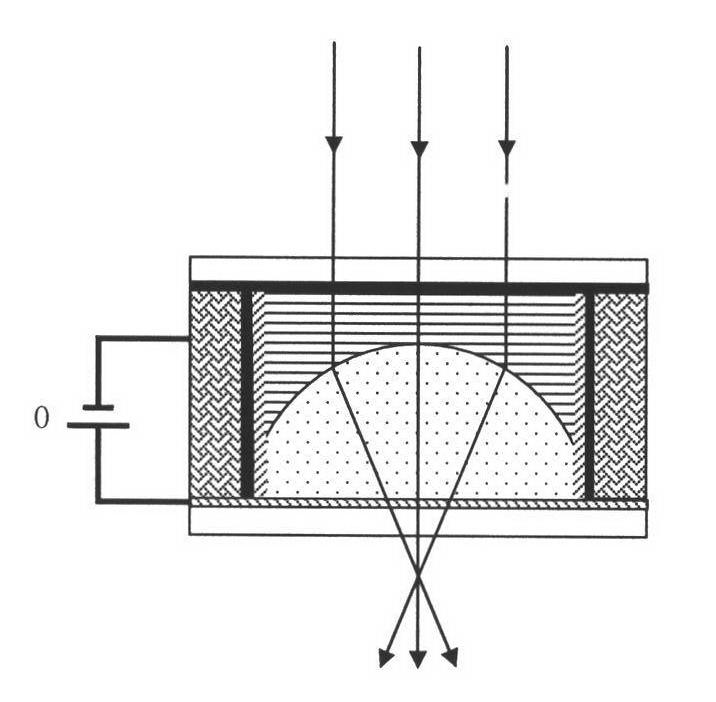

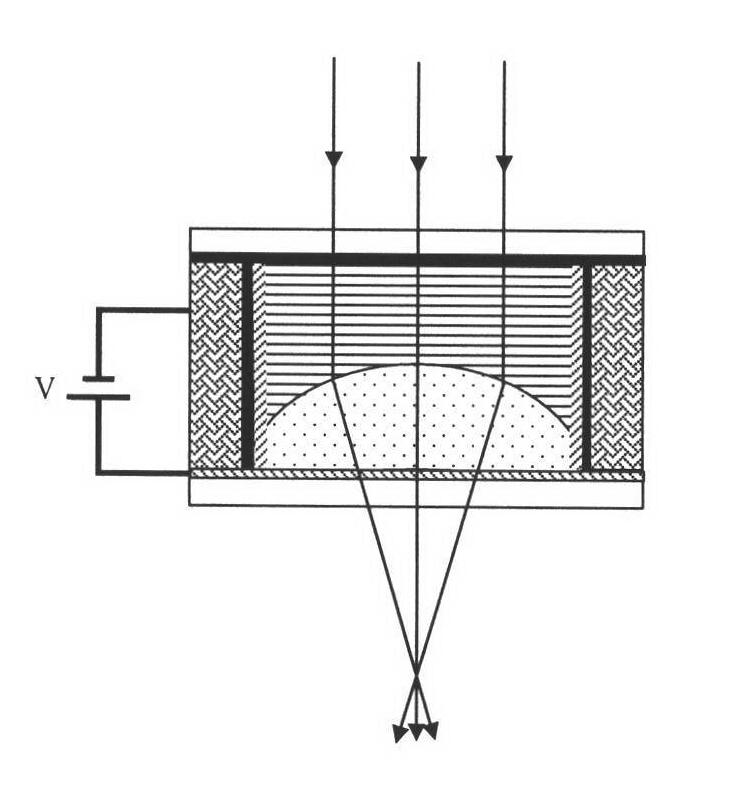

[0035] Embodiment 1: According to the present invention, the refractive index and surface tension of the ionic liquid used in the conductive solution of the liquid lens are greater than that of the insulating fluid. The ionic liquid can be C 8 h 15 IN 2 (density 1.2124g / cm 3 , refractive index 1.572, surface tension 54.7mN / m), the insulating fluid uses KF56 silicone oil (density 0.995g / cm 3 , refractive index 1.497, surface tension 26.5mN / m) and a small amount of organic additive phenyl bromide (density 1.495g / cm 3 , a mixture with a refractive index of 1.5590 and a surface tension of 38.14mN / m). The density difference between the conductor and the insulating fluid is adjusted by the mixing ratio of silicone oil and organic additives. The difference in viscosity can be adjusted by adding a surfactant to the conductor.

specific Embodiment 2

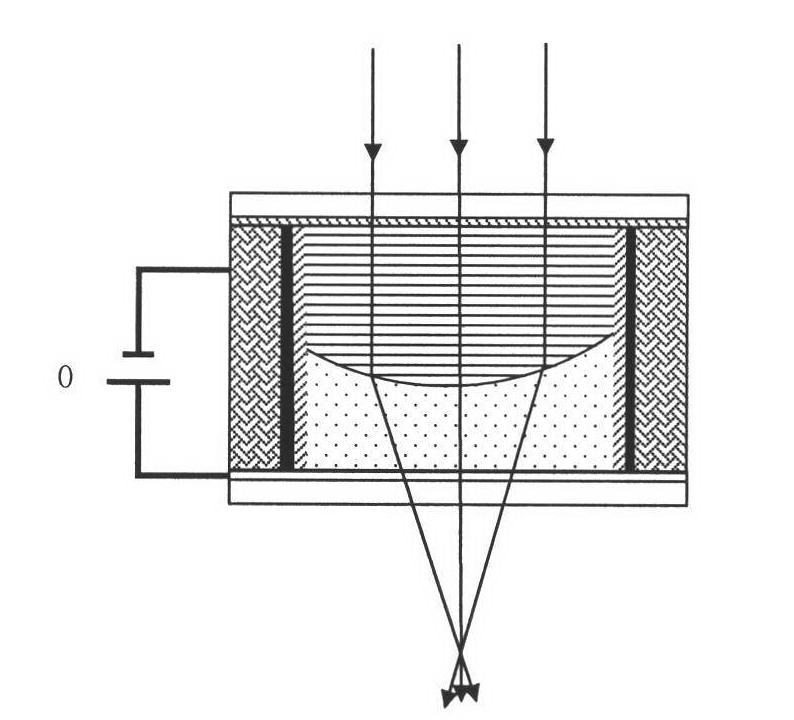

[0036] Embodiment 2: The refractive index and surface tension of the ionic liquid used in the conductive solution of the liquid lens according to the present invention are both lower than those of the insulating fluid. The conductive fluid adopts ionic liquid [Bmim]BF with small surface tension and refractive index 4 (density 1.120g / cm 3 , Refractive index 1.42, surface tension 46.6mN / m), the insulating fluid adopts phenylmethylsiloxane with high refractive index and good electrowetting performance. The density difference between the conductive fluid and the insulating fluid is determined by dissolving several percent carbon tetrabromocompounds in phenylmethylsiloxane (ρ=2.96g / cm 3 ) to adjust, the refractive index of the mixed insulating fluid is about 1.55 and the surface tension is greater than that of the conductive fluid. The difference in viscosity can be adjusted by adding a surfactant to the conductor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com