Preparation method and application of sulfonated polyether-ether-ketone-carboxylated titanium dioxide hybrid membrane

A technology for sulfonating polyetheretherketone and titanium dioxide, which is applied in electrochemical generators, fuel cell parts, fuel cells, etc., can solve the problems of proton exchange membranes that have not been reported in literature, achieve simple process and improve membrane performance. , the effect of low methanol permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

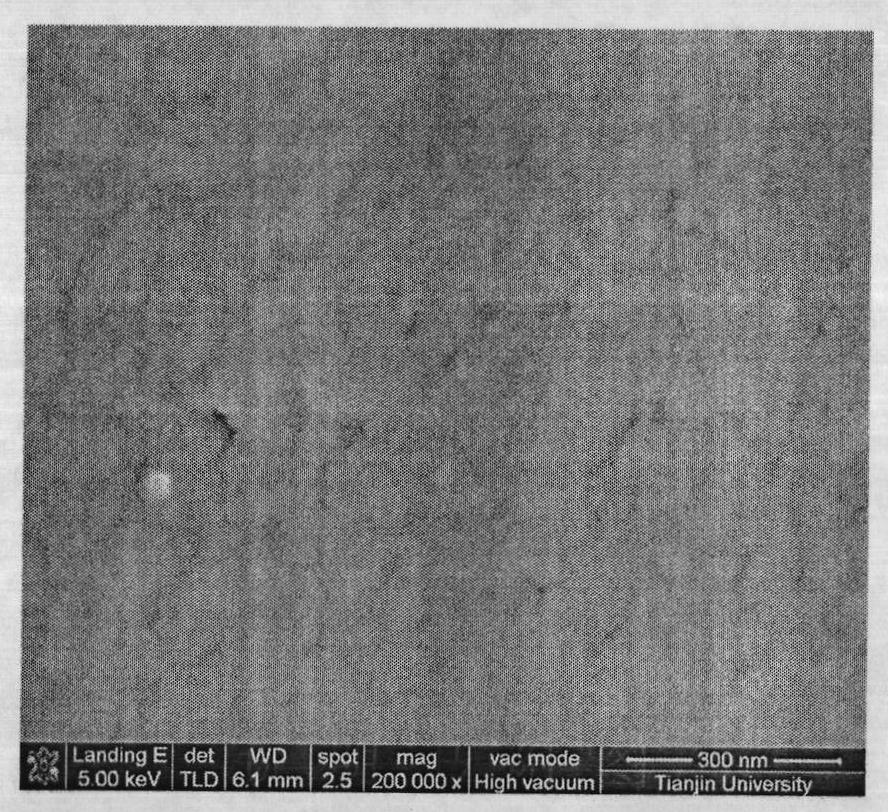

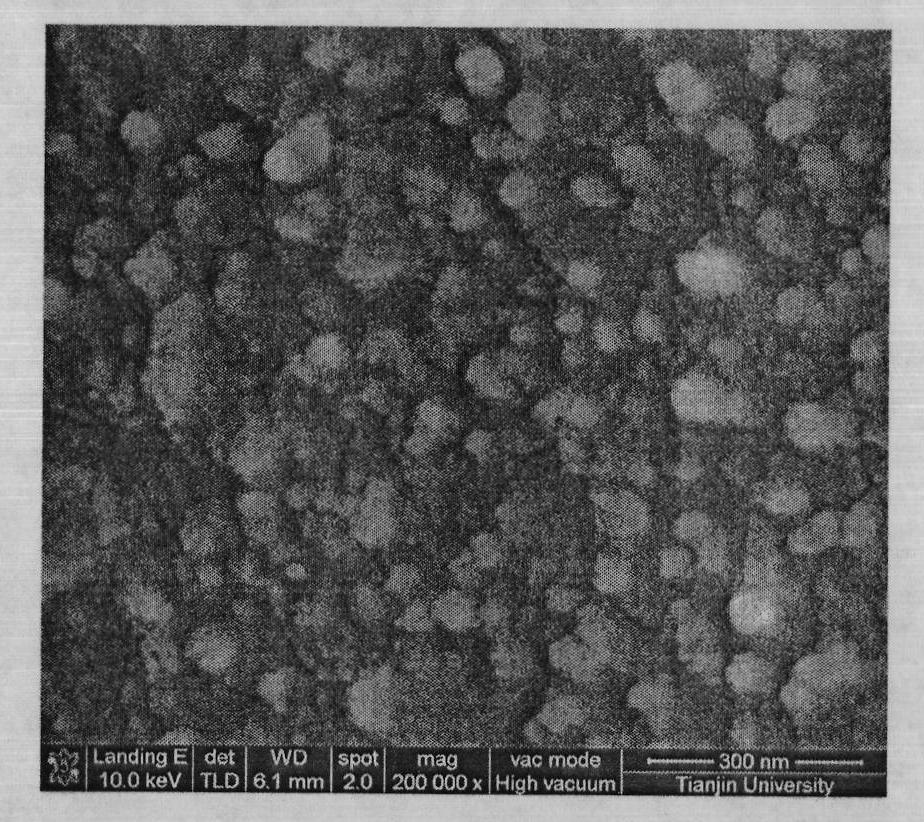

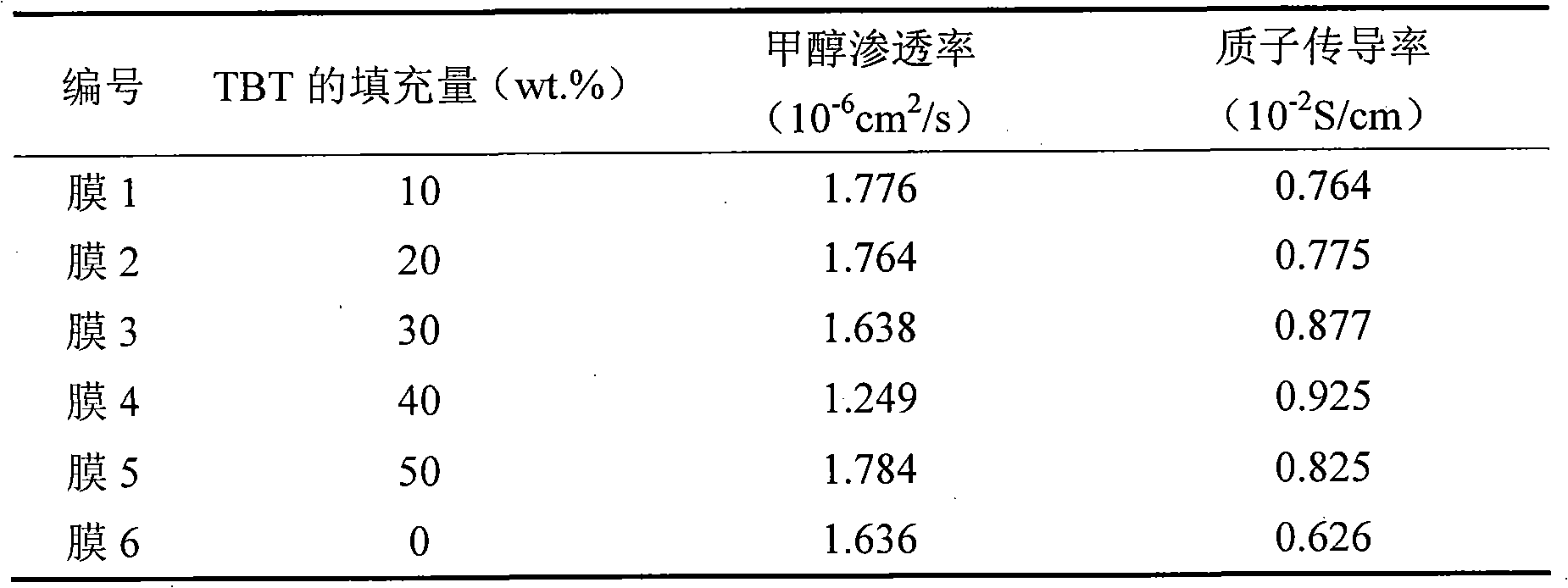

[0014] 0.7 g of sulfonated polyetheretherketone (SPEEK) was weighed and dissolved in 5 g of N,N-dimethylformamide (DMF), stirred at room temperature for 12 hours to obtain a SPEEK casting solution. At room temperature, 0.07 g of butyl titanate and 0.041 g of acetylacetone were mixed and added to 2 g of DMF, and stirred for 3 h, and then 0.0037 g of water with pH=1 was slowly added and stirred for 10 h to obtain a yellow transparent titanium dioxide sol. Then, 0.0033 g of 3,4-dihydroxyphenylpropionic acid was weighed and added to the obtained titanium dioxide sol to obtain a brownish red solution. Slowly mix the two solutions obtained above and stir at room temperature for 1 hour, filter and stand for degassing, pour the obtained casting solution onto a clean glass plate, and place it in an oven to dry at 60°C for 12 hours. Then heat up to 80°C and dry for 10 hours, and finally anneal at 120°C, remove the film and treat it in 2M sulfuric acid for 12 hours, then rinse with deion...

Embodiment 2

[0016] 0.7 g of sulfonated polyetheretherketone (SPEEK) was weighed and dissolved in 5 g of N,N-dimethylformamide (DMF), stirred at room temperature for 12 hours to obtain a SPEEK casting solution. At room temperature, 0.14 g of butyl titanate and 0.082 g of acetylacetone were mixed and added to 2 g of DMF, and stirred for 3 h, and then 0.059 g of water with pH=1 was slowly added and stirred for 10 h to obtain a yellow transparent titanium dioxide sol. Then, 0.0066 g of 3,4-dihydroxyphenylpropionic acid was weighed and added to the obtained titanium dioxide sol to obtain a brownish red solution. Slowly mix the two solutions obtained above and stir at room temperature for 1 hour, filter and stand for degassing, pour the obtained casting solution onto a clean glass plate, and place it in an oven to dry at 60°C for 12 hours. Then heat up to 80°C and dry for 10 hours, and finally anneal at 120°C, remove the film and treat it in 2M sulfuric acid for 12 hours, then rinse with deioni...

Embodiment 3

[0018] 0.7 g of sulfonated polyetheretherketone (SPEEK) was weighed and dissolved in 5 g of N,N-dimethylformamide (DMF), stirred at room temperature for 12 hours to obtain a SPEEK casting solution. At room temperature, 0.21 g of butyl titanate and 0.123 g of acetylacetone were mixed and added to 2 g of DMF, and stirred for 3 h, then slowly added 0.089 g of water with pH=1 and continued stirring for 10 h to obtain a yellow transparent titanium dioxide sol. Then 0.0099 g of 3,4-dihydroxyphenylpropionic acid was weighed and added to the obtained titanium dioxide sol to obtain a brownish red solution. Slowly mix the two solutions obtained above and stir at room temperature for 1 hour, filter and stand for degassing, pour the obtained casting solution onto a clean glass plate, and place it in an oven to dry at 60°C for 12 hours. Then heat up to 80°C and dry for 10 hours, and finally anneal at 120°C, remove the film and treat it in 2M sulfuric acid for 12 hours, then rinse with deio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com