Resin composition and production method of plastic product of resin composition

A technology of resin composition and kneader, which is applied in the field of manufacturing resin composition and its plastic products, can solve the problems of non-environmental protection, low work efficiency, easy to fall off, etc., achieve good environmental protection effect, improve work efficiency, and smooth lines Intermittent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0060] The above-mentioned resin composition is white or light gray. This example illustrates the resin composition of the present invention, its preparation method and the manufacturing method of the product by engraving the product to form black characters or patterns. Wherein the resin composition is proportioned according to the following mass percentages:

[0061] ABS resin 90%

[0062] Phosphorus 8%

[0063] Triphenyl Phosphate 2%

[0064] A method of manufacturing a plastic product includes the following steps:

[0065] (1) Select the materials according to the above formula and put them into the kneader, knead and knead for 40-60 minutes under vacuum, high pressure, and 200-220°C until a uniform soft rubber is masticated;

[0066] (2) masticating the kneaded soft glue with a double-roll mill under a heating condition of 180 to 200° C., pressing the soft glue into a sheet to form a resin composition;

[0067] (3) cooling the flaky rubber block of the resin compositi...

example 2

[0073] The resin composition is proportioned according to the following mass percentages:

[0074] PE resin 50%

[0075] PP resin 25%

[0076] Bromine 5%

[0077] Hexabromobenzene 3%

[0078] Decabromodiphenylethane 1%

[0079] Tetrabromobisphenol A 1%

[0081] A method of manufacturing a plastic product includes the following steps:

[0082] (1) Select the materials according to the above formula and put them into the kneader, knead and knead for 40-60 minutes under vacuum, high pressure, and 200-220°C until a uniform soft rubber is masticated;

[0083] (2) masticating the kneaded soft glue with a double-roll mill under a heating condition of 180 to 200° C., pressing the soft glue into a sheet to form a resin composition;

[0084] (3) cooling the flaky rubber block of the resin composition, and pulverizing to form fine flaky particles;

[0085] (4) take the granule of step (3) as raw material injection molding into telephone set button;...

example 3

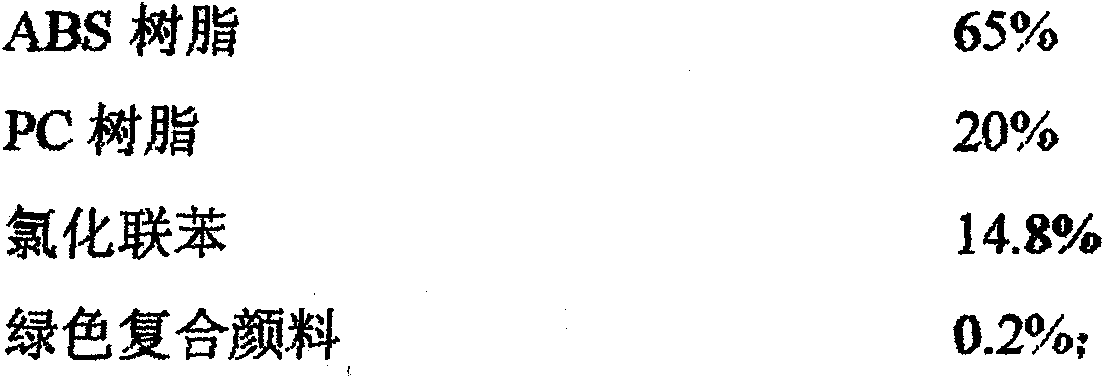

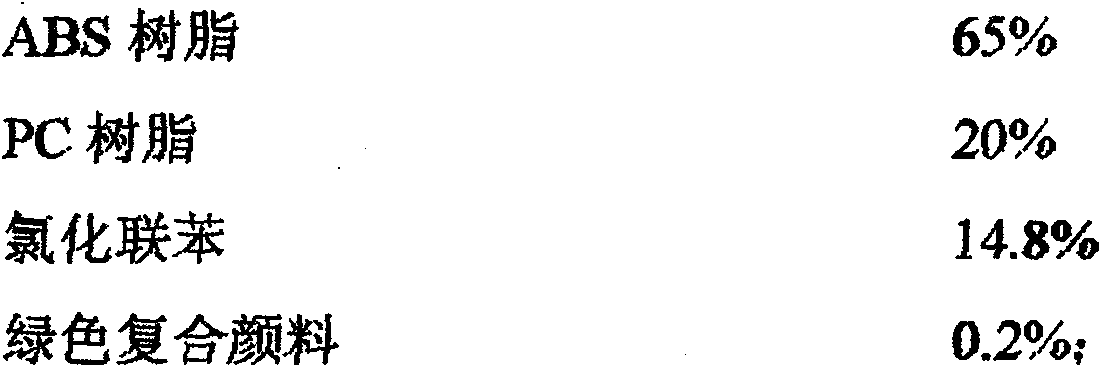

[0088] The resin composition is proportioned according to the following mass percentages:

[0089] PC resin 99.999%

[0090] Phosphorus 0.001%.

[0091] A method of manufacturing a plastic product includes the following steps:

[0092] (1) Select the materials according to the above formula and put them into the kneader, knead and knead for 40-60 minutes under vacuum, high pressure, and 200-220°C until a uniform soft rubber is masticated;

[0093] (2) masticating the kneaded soft glue with a double-roll mill under a heating condition of 180 to 200° C., pressing the soft glue into a sheet to form a resin composition;

[0094] (3) cooling the flaky rubber block of the resin composition, and pulverizing to form fine flaky particles;

[0095] (4) take the granule of step (3) as raw material injection molding into telephone set button;

[0096] (5) Put the phone buttons into the laser engraving machine, and perform laser engraving with a power of 50W and a laser speed of 7Kmm / s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com