Manufacturing technique of high wear-resisting polyurea elastomer spraying layer

A technology of polyurea elastomer and spray coating, which is applied in the direction of polyurea/polyurethane coatings, coatings, liquid injection devices, etc., can solve the problems that the performance of the material formulation system cannot meet the wear-resistant technical indicators, and achieve great social significance. Effect of increased safety, optimum coating elasticity and tear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with specific preparation process embodiment, the fact of the present invention is described in detail

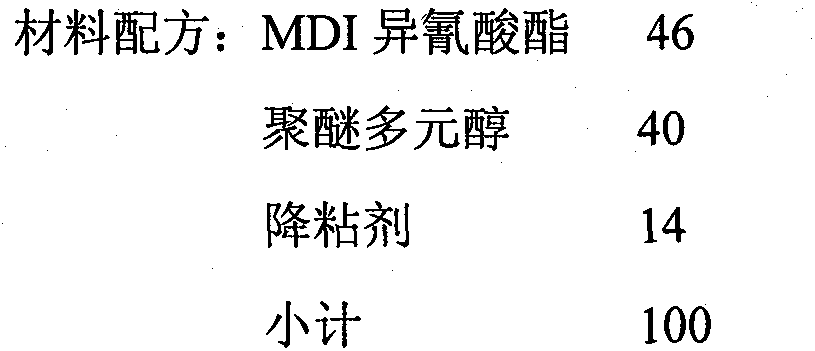

[0037] Step 1: Preparation of Component A

[0038]

[0039] Add 36 parts of mixed MDI isocyanate into a nitrogen-filled reaction kettle and heat it to 60°C, then add 40 parts of mixed polyether polyols that have been dehydrated in high temperature vacuum to the kettle for 1 to 2 hours, and then 70~ At 85°C for 3.5 hours, a semi-prepolymer with an -NCO% of 7-9% can be obtained. After cooling down to 60°C, add 10 parts of liquefied MDI and MDI-50, and 14 parts of viscosity reducer. After measuring, put it into the batching kettle, stir and disperse at high speed for 30 minutes, then pack it in barrels, control the temperature at 40-50°C, measure- The NCO% is 8.2%.

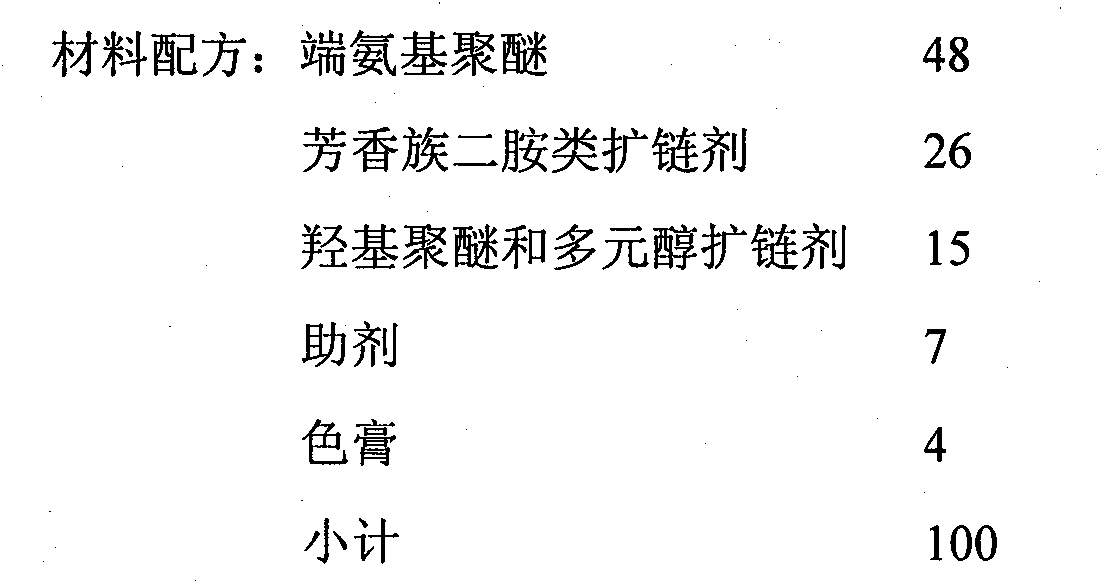

[0040] Step 2: Component B Preparation

[0041]

[0042] Mix 26 parts of diamine chain extender, 48 parts of amino-terminated polyether, 15 parts of hydroxyl polyether and poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com