Digital printing active dye jet ink

A technology of reactive dyes and inkjet inks, which is applied in dyeing, textiles and papermaking, etc. It can solve the problems of not being able to store for a long time, the ink is easy to decompose, and the nozzles are easy to be blocked, and achieve good color fastness and color reproducibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

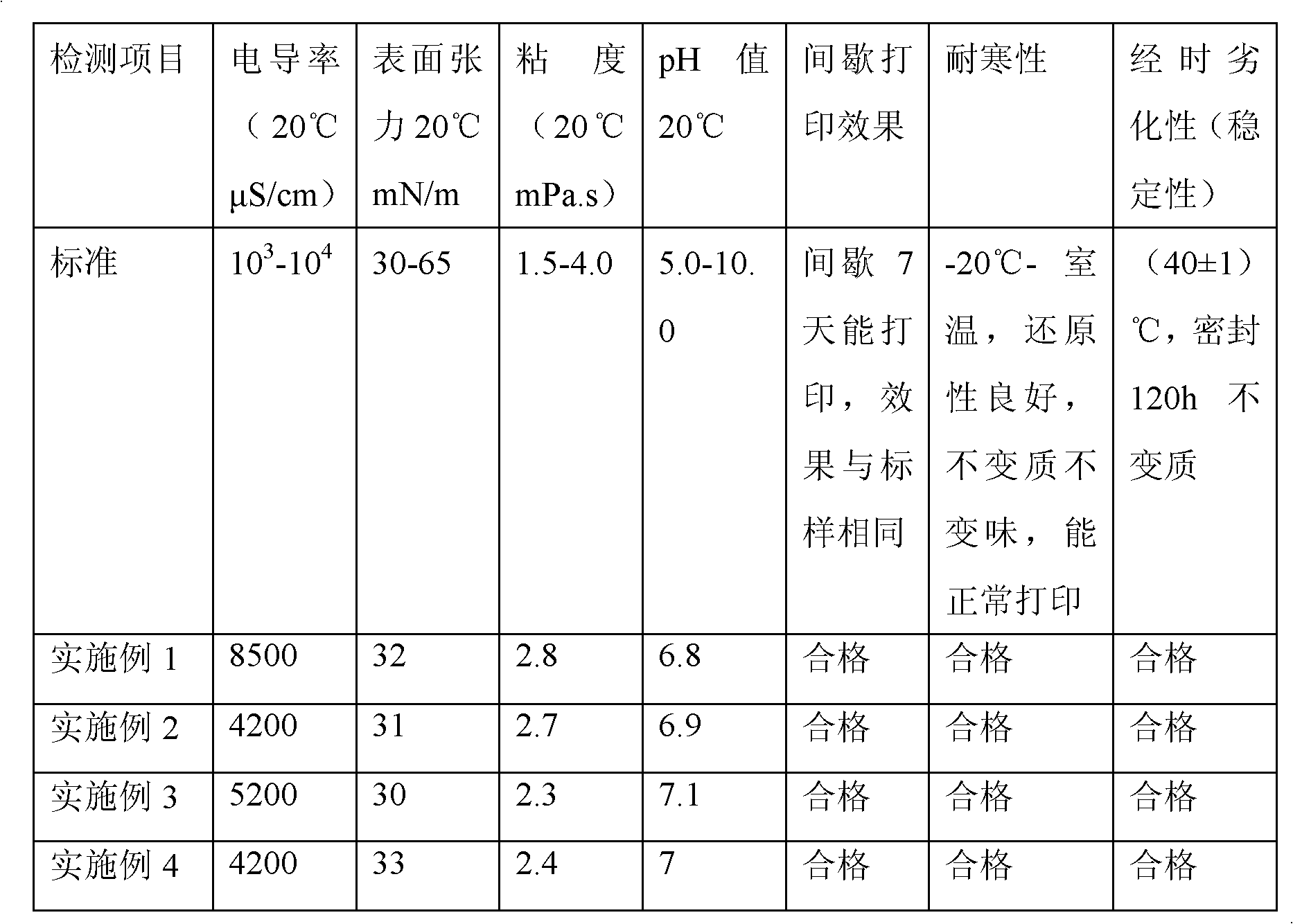

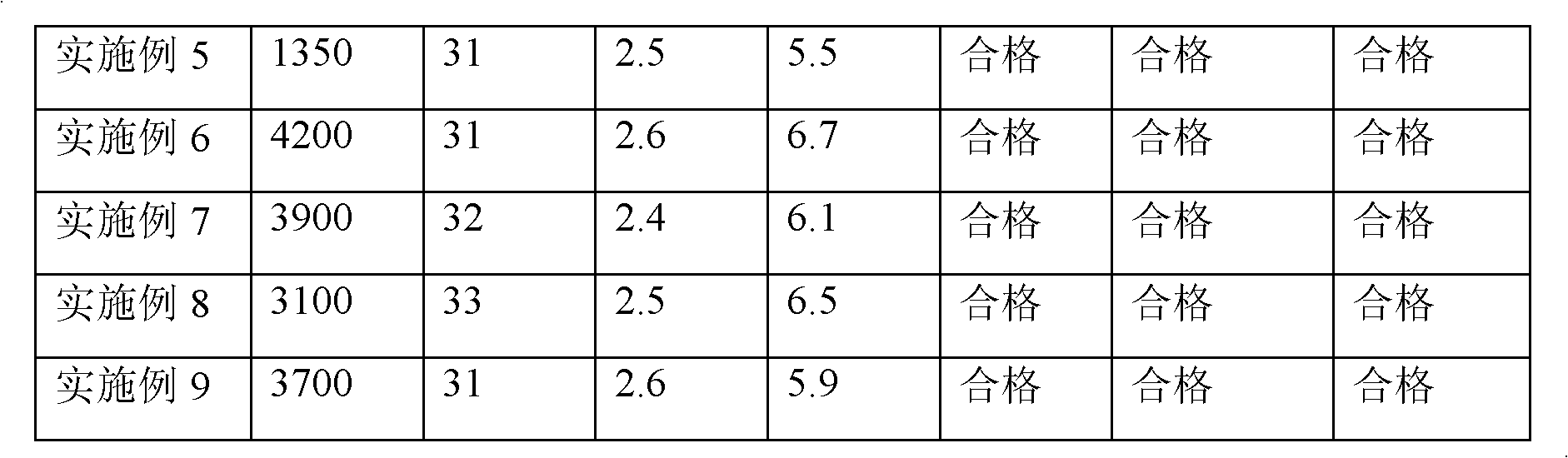

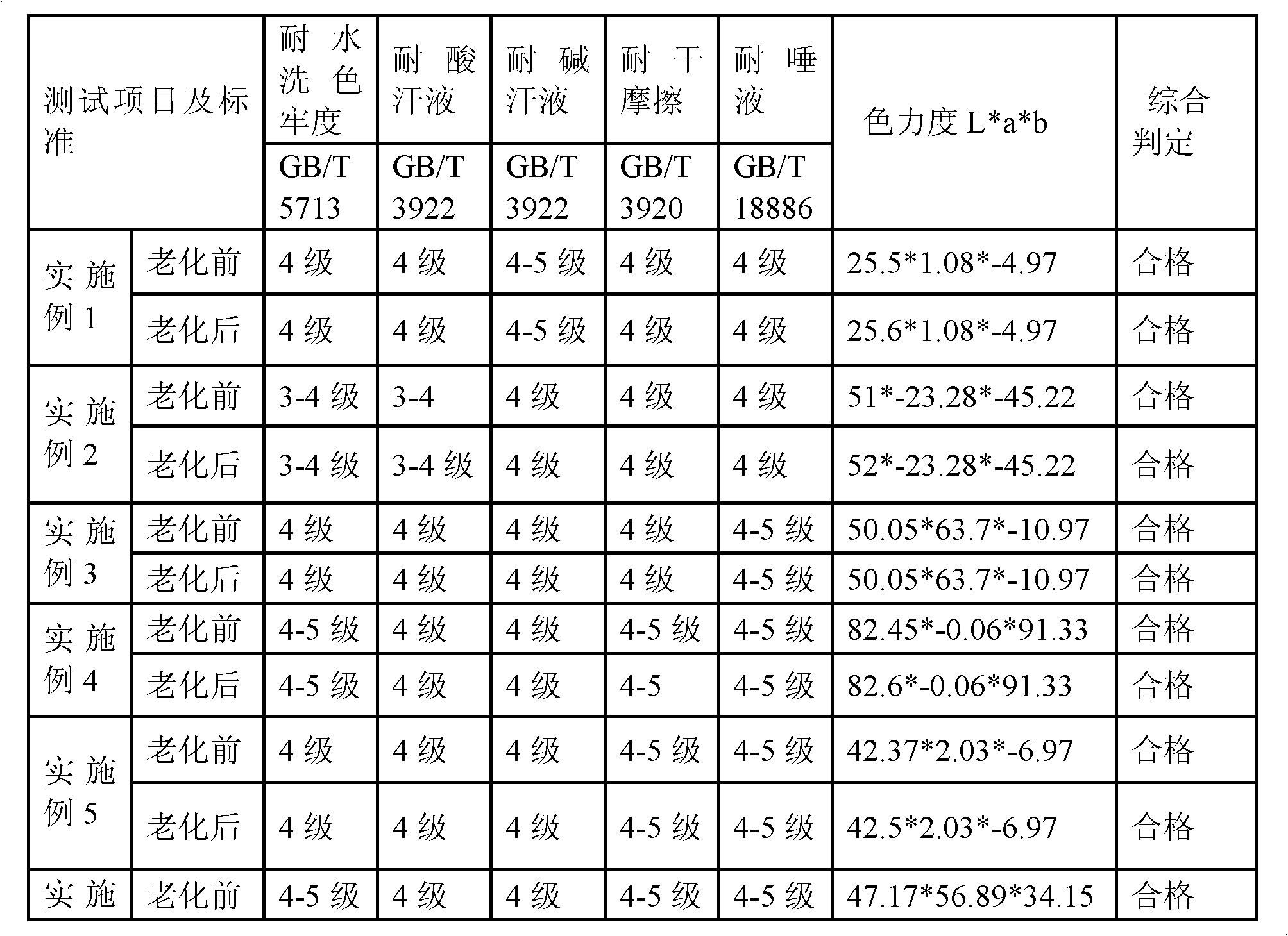

Examples

Embodiment 1

[0020] Digital printing reactive dye inkjet ink, which comprises the following components by weight percentage: C.I. Reactive Black 39 18%, C.I. Reactive Brown 2 1%, C.I. Reactive Brown 11 1%, Diethylene Glycol Ether 5%, Polyethylene Glycol 1000 1%, triethylene glycol 4%, EH-3 surface tension regulator 0.1%, BYK-345 surface tension regulator 0.1%, sodium dihydrogen phosphate 0.05%, disodium hydrogen phosphate 0.05%, 5-chloro-2 -1.5% of methyl-4-isothiazolin-3-one, and the rest is deionized water; the above components are mixed uniformly in proportion and then filtered through a 0.22 micron filter membrane to obtain a digital printing reactive dye inkjet ink. In this embodiment, the EH-3 surface tension regulator produced by Dow Company of the United States and the BYK-345 surface tension regulator produced by BYK Chemical Company are preferred.

Embodiment 2

[0022] Digital printing reactive dye inkjet ink, which comprises the following components by weight percentage: C.I. Reactive Blue 72 3%, C.I. Reactive Blue 14 8%, 1,5-pentanediol 15%, dimethylacetamide 5%, ethyl Glycol benzyl ether 6%, EH-3 surface tension regulator 0.3%, BYK-348 surface tension regulator 0.5%, citric acid 2%, triethanolamine 1%, 5-chloro-2-methyl-4-isothiazole Lin-3-one 0.3%, the rest is deionized water. The above components are uniformly mixed in proportion and then filtered through a 0.22 micron filter membrane to obtain a digital printing reactive dye inkjet ink. In this embodiment, the EH-3 surface tension regulator produced by Dow Company of the United States and the BYK-348 surface tension regulator produced by BYK Chemical Company are preferred.

Embodiment 3

[0024] Digital printing reactive dye inkjet ink, which comprises the following components by weight percentage: C.I. reactive red 245 10%, C.I. reactive red 31 2%, 1,5-pentanediol 10%, triethylene glycol 10%, ethylene glycol Alcohol benzyl ether 5%, BYK-348 surface tension regulator 1.2%, EH-3 surface tension regulator 0.8%, lactic acid 0.5%, triethanolamine 0.3%, 5-chloro-2-methyl-4-isothiazoline- 0.5% of 3-ketone, and the rest is deionized water. The above components are uniformly mixed in proportion and then filtered through a 0.22 micron filter membrane to obtain a digital printing reactive dye inkjet ink. In this embodiment, the EH-3 surface tension regulator produced by Dow Company of the United States and the BYK-348 surface tension regulator produced by BYK Chemical Company are preferred.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com