Preparation method of silver red ceramic pigment

A ceramic pigment, silver red technology, applied in fibrous fillers and other directions, can solve the problems of insufficient pigment, insufficient color strength, and high firing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

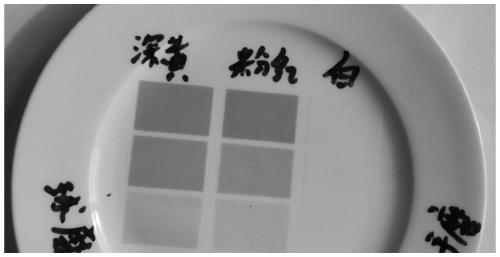

Image

Examples

Embodiment 1

[0039] A preparation method for silver-red ceramic pigments, comprising the following steps: preparation of acid solution: adding 82g of zirconium nitrate and 1.2g of silver nitrate into water, stirring and dissolving; preparation of lye solution: adding 30g of sodium hydroxide and 2g of sodium carbonate into water, stirring and dissolving ;Acid-base titration: drop the acid solution and alkali solution into the water at the same time, the titration rate is 1mL / min, stir while adding, the titration process controls the pH to 7~8, after the titration is completed; continue to stir for 0.5h; Suction filtration, methanol washing, until the conductivity of the cleaning solution is less than 100 μs / cm, then dry in a drying oven at a temperature of 70°C to obtain the raw meal; add the raw meal, potassium bifluoride in an amount of 8% of the raw meal weight, Add oxalic acid in an amount of 1% of the weight of the raw material into a ball mill for ball milling; after ball milling, the ...

Embodiment 2

[0042] A preparation method for silver-red ceramic pigments, comprising the following steps: preparation of acid solution: adding 85.5 g of zirconium nitrate and 0.73 g of silver nitrate into water, stirring and dissolving; preparation of lye solution: adding 31.8 g of sodium hydroxide and 1.2 g of sodium carbonate into water , stir to dissolve; acid-base titration: drop acid and lye into water at the same time, the titration rate is 0.5mL / min, stir while adding, control the pH of the titration process to be 7-8, after the titration is completed; continue to stir for 0.5h ; Suction filter the sediment and wash with absolute ethanol until the conductivity of the cleaning solution is less than 100 μs / cm, then dry it in a drying oven at a temperature of 60°C to obtain the raw meal; add the raw meal to 10% of the weight of the raw meal A certain amount of ammonium bifluoride and 3% dextrin added to the weight of the raw material were added to the ball mill for ball milling; after b...

Embodiment 3

[0045] A preparation method of silver-red ceramic pigment, comprising the following steps: preparation of acid solution: adding 83.76g of zirconium nitrate and 1.46g of silver nitrate into water, stirring and dissolving; preparation of lye solution: adding 31.2g of sodium hydroxide and 2.4g of sodium carbonate into water , stir to dissolve; acid-base titration: drop the acid solution and alkali solution into the water at the same time, the titration rate is 0.8mL / min, stir while adding, the titration process controls the pH to 7-8, after the titration is completed; continue to stir for 1h; Suction filter the sediment and wash with ethylene glycol until the conductivity of the cleaning solution is less than 100μs / cm, then dry it in a drying oven at a temperature of 80°C to obtain the raw meal; add the raw meal to 5% of the weight of the raw meal Sodium bifluoride and urea in an amount of 5% of the weight of the raw material were added to the ball mill for ball milling; after bal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com