A reactive ink for digital printing

A reactive ink, digital printing technology, applied in textiles and papermaking, dyeing and other directions, can solve the problem of wool fabric color strength, color fastness and color reproducibility poor, reduced textile color fastness, phosphate environmental pollution, etc. problems, to achieve significant environmental and economic benefits, to avoid the reduction of color fastness, and to achieve long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

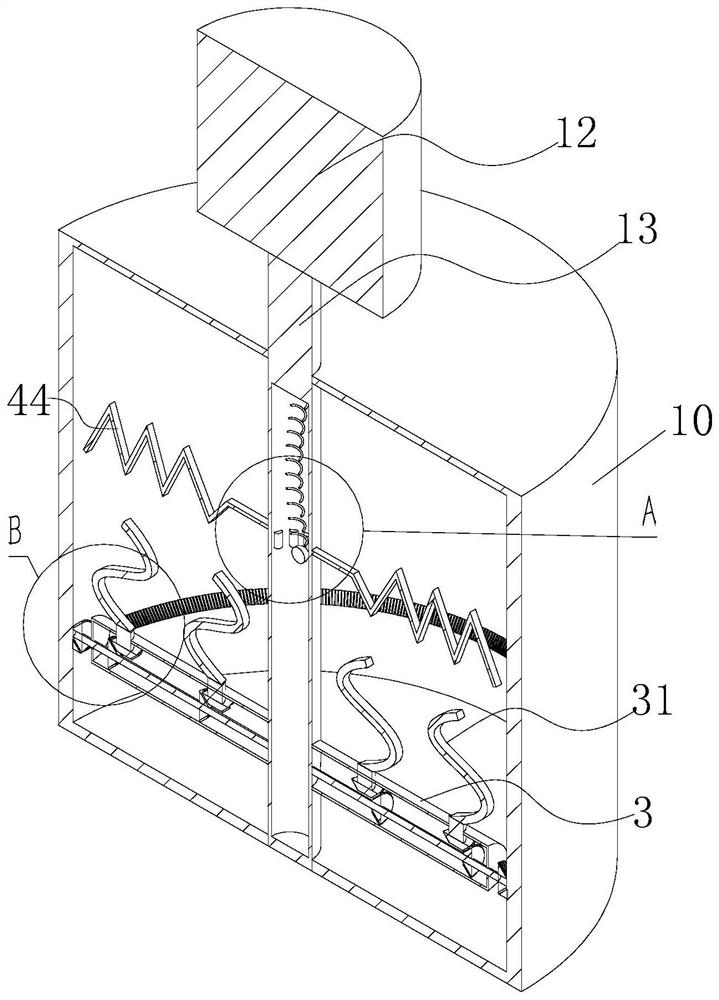

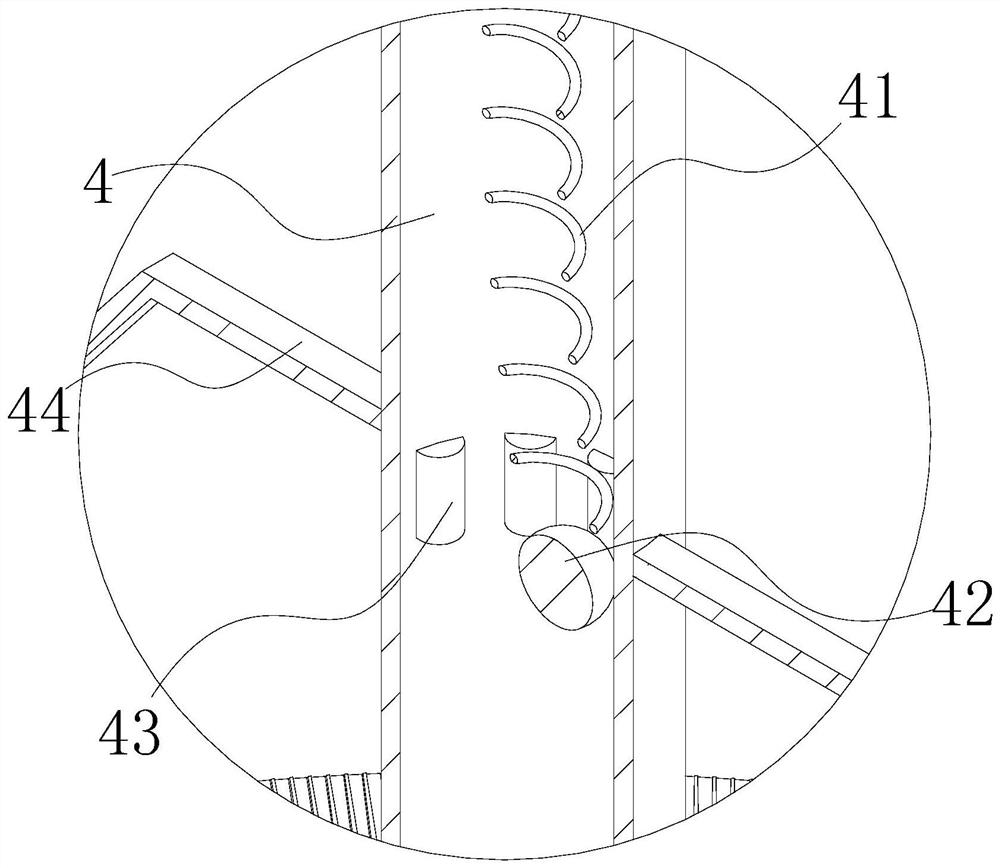

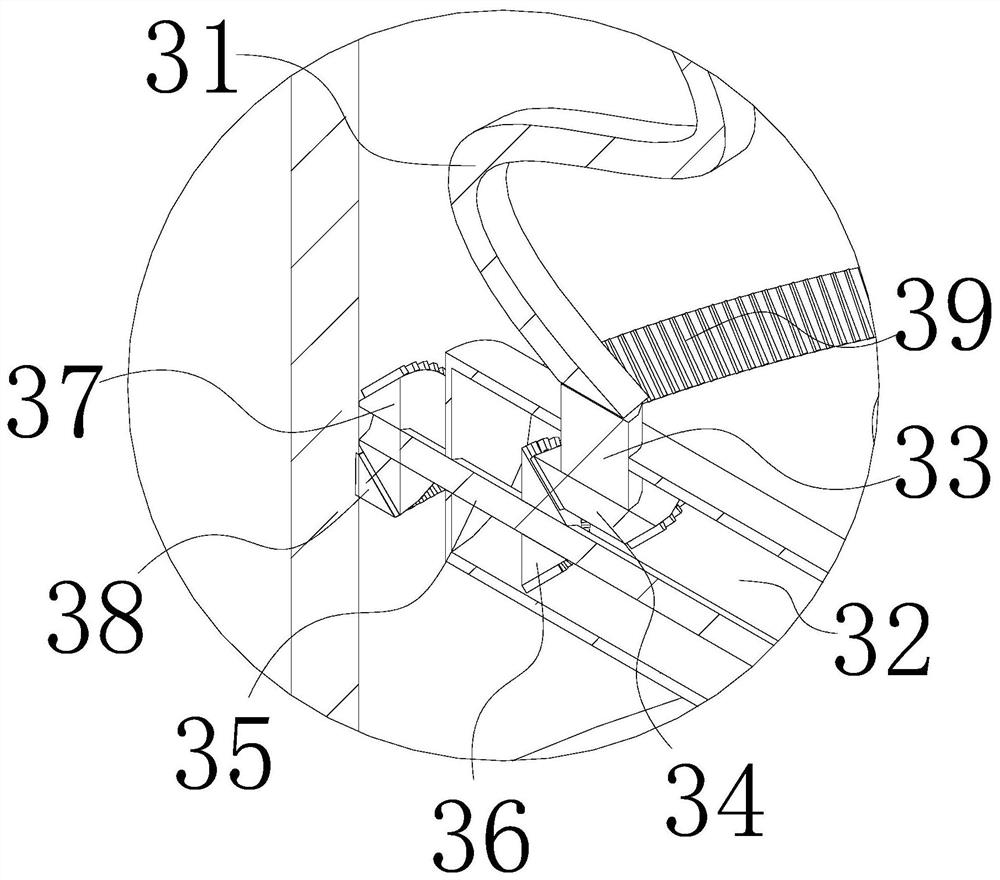

[0030] Reactive dye inkjet ink for digital printing, which includes the following components by weight percentage: 12% reactive black 5, 10% triethylene glycol, 0.5% alkoxylated alcohol, 2% triethanolamine, 0.2% Thiazole fungicides, 7% caprolactam, 1% triethylamine, 2% NP-10, and the rest are deionized water. Put the above components into the mixing equipment according to the corresponding content, stir for 2 hours and mix them evenly, then mature them at 60°C for 24 hours, and filter them with 0.5 micron medium-speed filter paper to obtain the final product digital printing reactive ink; Figure 1-3 As shown, the stirring device includes a stirring tank 10, a stirring shaft 13, a first driving member 12, a stirring rod 3, a deflector 31, a first installation cavity 32, a rotating shaft 33, a first bevel gear 34, a driving shaft 35, The second bevel gear 36, the third bevel gear 37, the annular fixed plate 38, the teeth 39 and the vibrating assembly, the upper and lower ends o...

Embodiment 2

[0032] Digital printing reactive dye inkjet ink, which includes the following components by weight percentage: 15% reactive brilliant red X-BB, 12% triethylene glycol, 1% alkoxylated alcohol, 2% triethanolamine, 0.2% thiazole fungicide, 10% caprolactam, 1% triethylamine, 1.5% NP-10, and the rest are deionized water. Stir the above components according to the corresponding content for 2 hours and mix them evenly, then mature them at 60°C for 24 hours, and filter them with 0.5 micron medium-speed filter paper to obtain the final product digital printing reactive ink.

Embodiment 3

[0034] Reactive dye inkjet ink for digital printing, which includes the following components by weight percentage: 17% of C.L. reactive blue 49, 11% of 1,2 propylene glycol, 1% of alkoxylated alcohol, 2% citric acid, 0.4% thiazole fungicide, 8% caprolactam, 2% triethylamine, 2% NP-10, and the rest are deionized water. Stir the above components according to the corresponding content for 2 hours and mix them evenly, then mature them at 60°C for 24 hours, and filter them with 0.5 micron medium-speed filter paper to obtain the final product digital printing reactive ink.

[0035] detection

[0036] Conductivity (20 ℃, μS / cm), viscosity (20 ℃, nPa s), pH value (20 ℃), liquid dye low temperature stability, printing fluency and storage stability and standard to embodiment 1-3 For comparison, the results are shown in Table 1:

[0037] Table 1

[0038]

[0039] As can be seen from Table 1, the detection results of the reactive inks prepared in Examples 1-3 all meet the standards...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com