Near-infrared vision sensing detection device for large-scale high-temperature forgeable piece

A detection device and near-infrared technology, which are applied in measurement devices, optical devices, electrical radiation detectors, etc., can solve the problems of high misjudgment rate, limited promotion, and high cost of infrared temperature measuring instruments, and achieve low prices and equipment. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

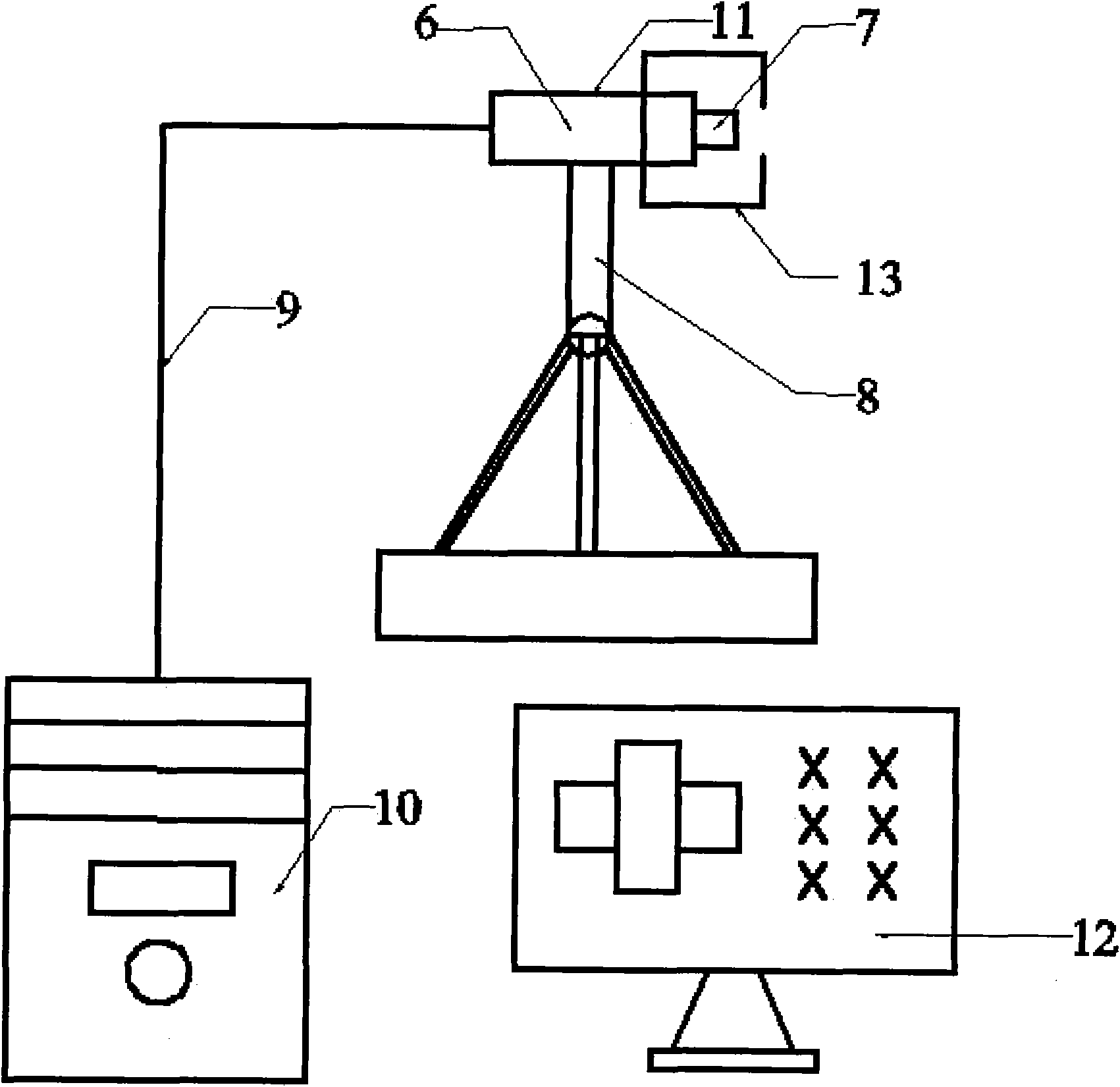

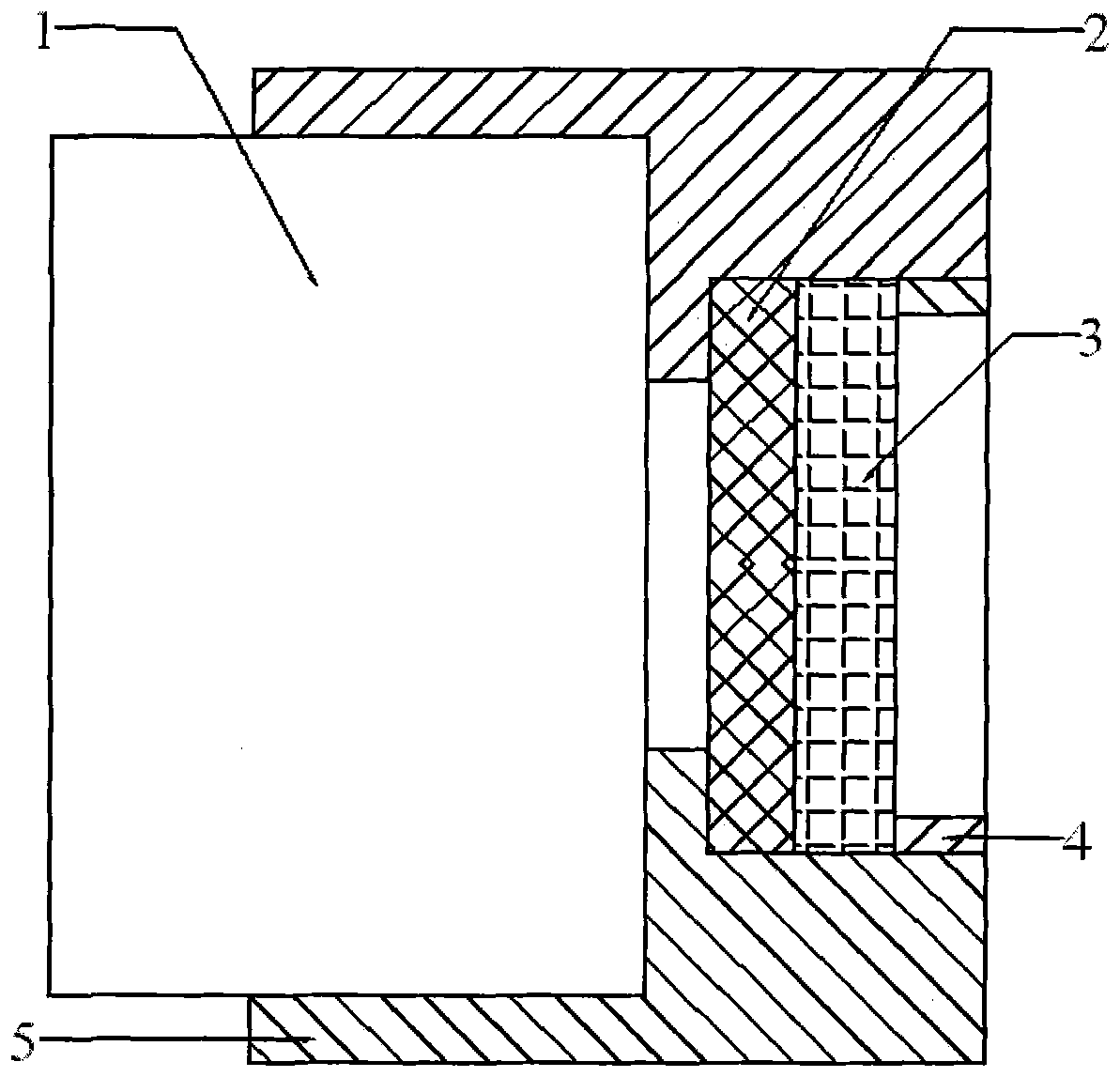

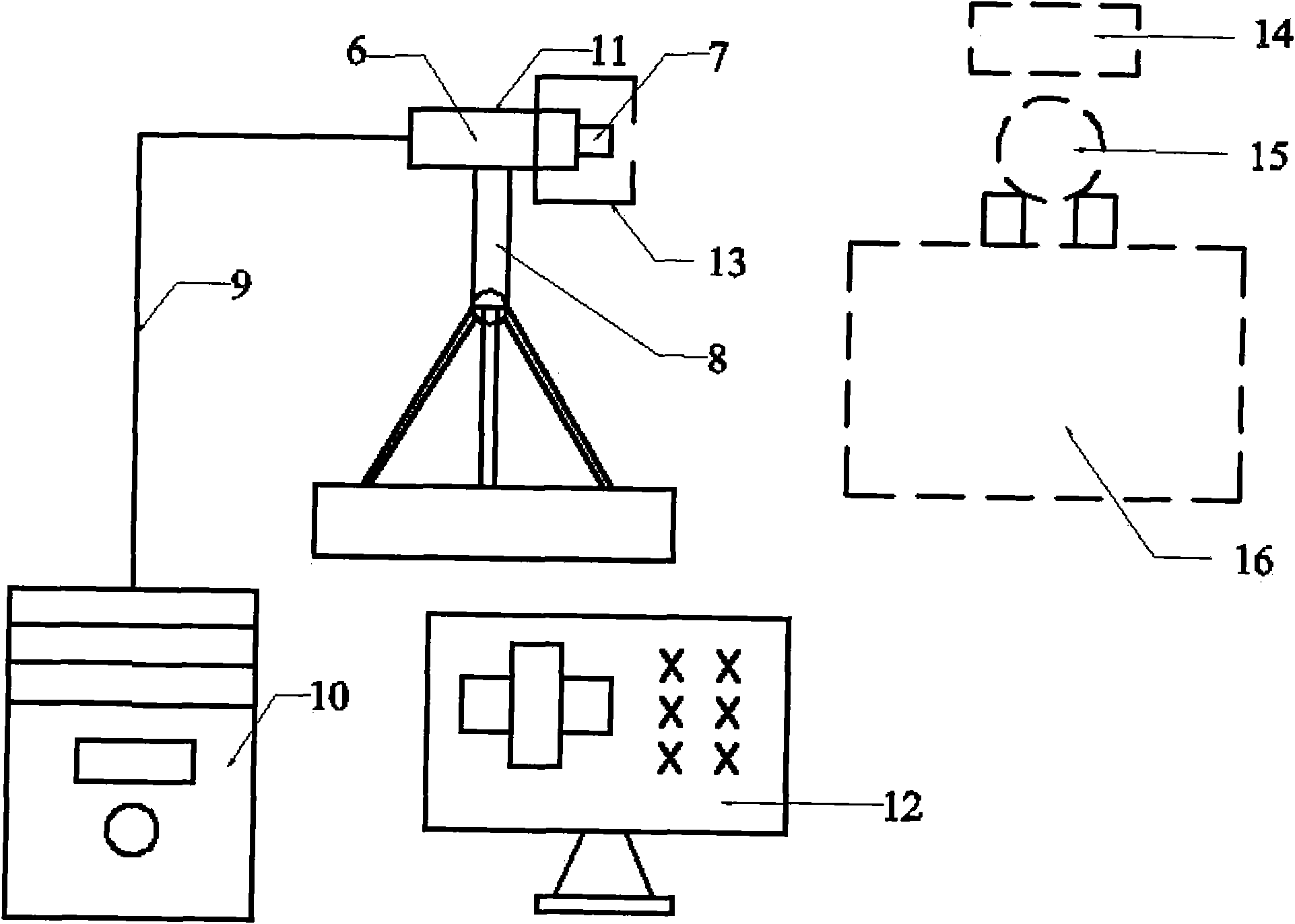

[0010] combine figure 1 and figure 2 , a kind of near-infrared sensing and detecting device for large-scale high-temperature forgings proposed by the present invention, which consists of a megapixel camera (1), a high-pass filter (2), an optical glass sheet (3), a fixed barrel (4), and a lens barrel (5), composed of a near-infrared digital CMOS camera (6), a camera bracket (8), a USB data cable (9), a visual information processing controller (10), a shielding box (11) and a light-shielding structural member (13). combine image 3 , the large-scale high-temperature forging near-infrared sensing detection device of the present invention forms a test system with the large-scale high-temperature forging (15), the forging hammer (14), and the operating platform (16). The present invention consists of a high-pass filter (2), an optical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com