Controllable method for preparing atomic force microscope needlepoint with carbon nano tube

An atomic force microscope and carbon nanotube technology, which is applied in scanning probe microscopy, scanning probe technology, gaseous chemical plating, etc. High-resolution, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

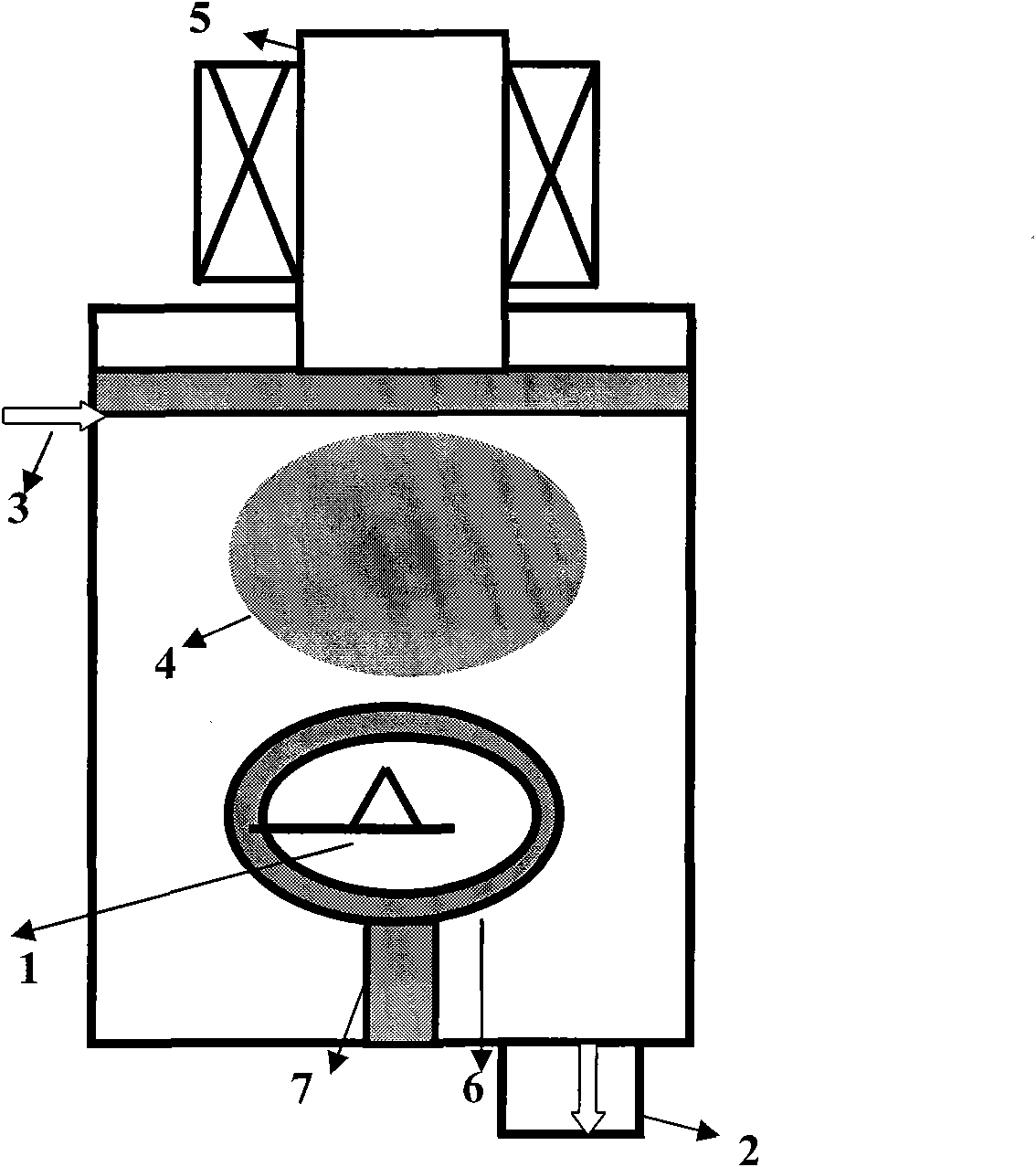

[0021] The invention uses the electrochemical reduction method to deposit nickel nanoparticles of a certain size on the tip of the atomic force microscope, and then uses the PECVD method to grow a single carbon nanotube on the nickel nanoparticle, and develops a process for preparing the tip of the atomic force microscope from the carbon nanotube.

[0022] The technical solutions of the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

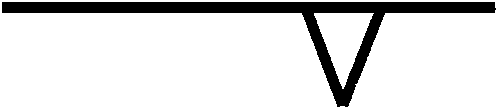

[0023] see figure 1 , figure 1 is a schematic diagram of an atomic force microscope tip. The atomic force microscope tip in the figure is a Si tip. The tip is small in size and light in weight, making it easy to image with an atomic microscope. The length of its tip is tens of micrometers.

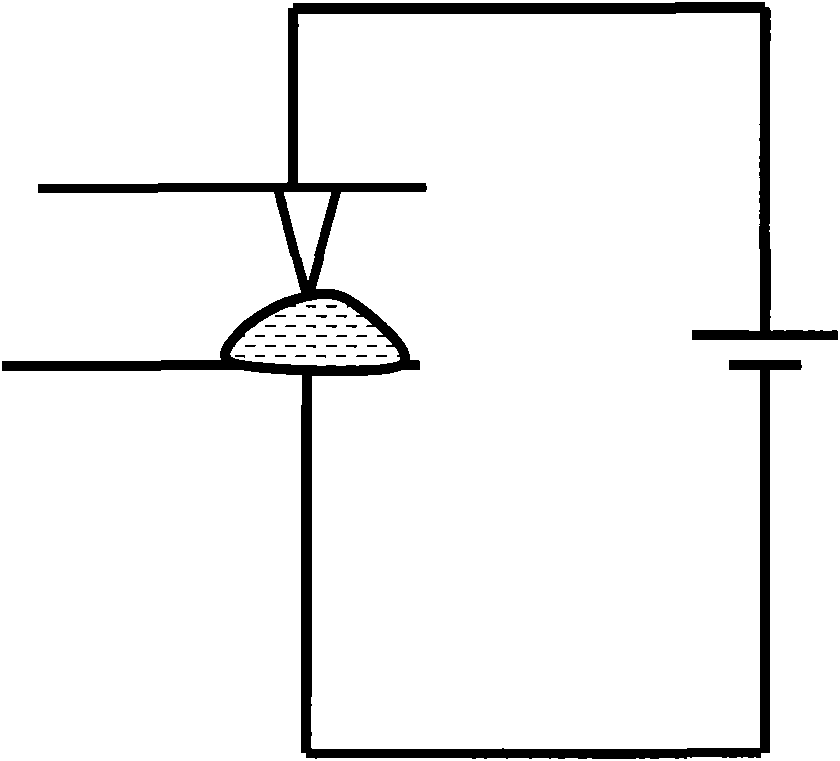

[0024] see figure 2 , figure 2 is a schematic illustration of the deposition of nickel nanoparticles on the tip of an atomic force microscope. The steps of electrochemical re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com