Method for detecting pinhole type growth defect

A pinhole and defect technology, which is applied in the detection field of semiconductor pinhole growth defects, can solve problems such as burning defects, waste of production costs, and no help

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the purpose, technical solution, and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

[0027] In the manufacturing process of semiconductor MOSFET devices, in order to detect the growth of MOSFET devices, a semiconductor silicon substrate is placed as a control piece at the same time, and the grown control piece is used as a sample for failure analysis to reflect the performance of the actually grown MOSFET device. The specific steps of the detection method for pinhole growth defects on the oxide layer of the chip gate are as follows:

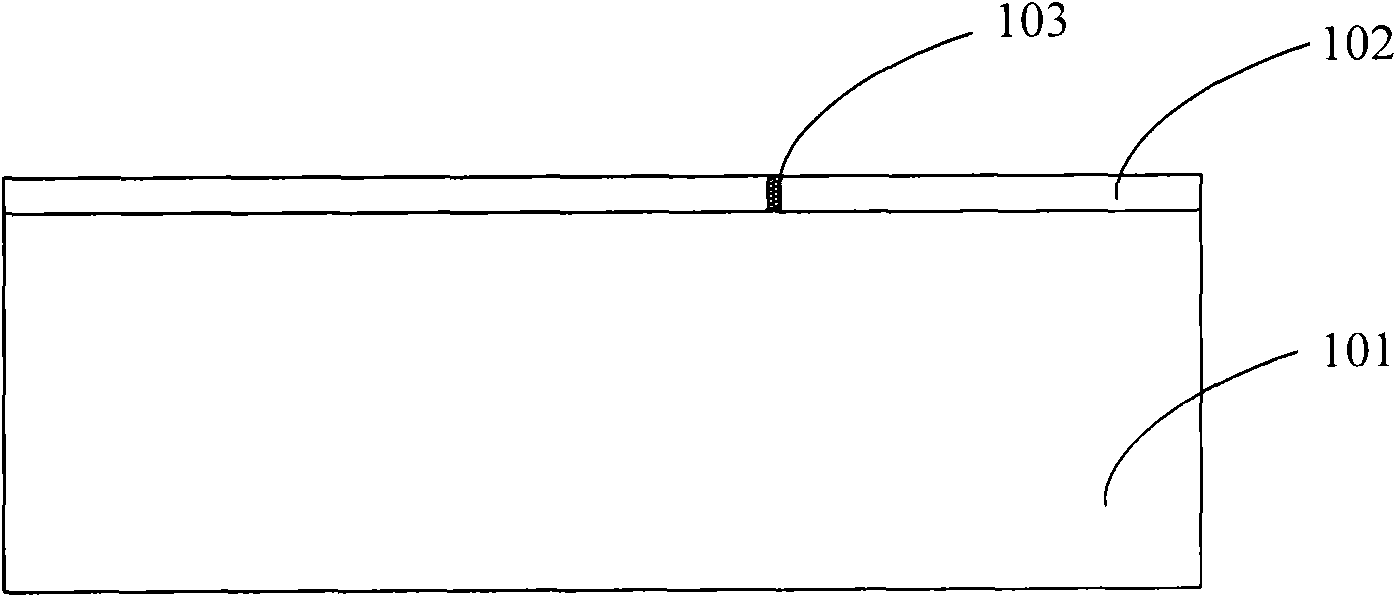

[0028] Step 1, growing a silicon dioxide gate oxide layer 102 on the semiconductor silicon substrate 101, such as figure 1 As shown, there are pinhole growth defects 103 on the gate oxide layer 102;

[0029] In this step, the method for growing the silicon dioxide gate oxide layer 102 is furnace tube gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com