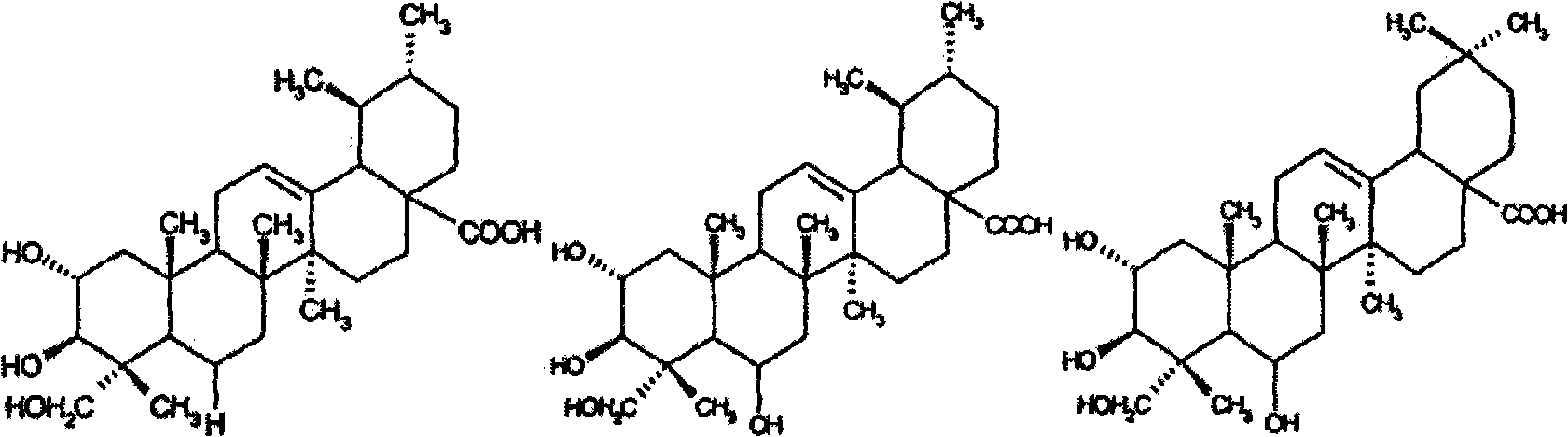

Method for extracting and separating asiaticoside by countercurrent extraction combined with membrane separation

A technology for extracting centella glycosides and countercurrent extraction, which is applied in the field of countercurrent extraction combined with membrane separation, extraction and separation of asiaticosides, can solve the problems of complex procedures, cumbersome operations, and large solvent volumes, and achieve a high degree of operation automation. The filter equipment is simple and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Take Centella asiatica hay (the total glucoside content of Centella asiatica is 1.2%) 100kg and put into countercurrent extractor, heat 600L pure water in liquid storage tank, pure water is input instant heater with pump (pure water is heated to 95 -100°C) after heating, carry out countercurrent extraction of the Centella asiatica raw material in the extraction tank. During the extraction process, the temperature in the extraction tank is controlled at 95-100°C, extract for 90 minutes, and release the extract; add 600L of pure water to the extraction tank , carry out the second countercurrent extraction, the temperature in the extraction tank is controlled at 95-100 ° C, extract for 90 minutes, and release the extract; add 600L pure water to the extraction tank, and perform the third countercurrent extraction, the temperature in the extraction tank is controlled at 95 Extract at -100°C for 90 minutes, release the extract; combine the extracts and filter to obtain 1500 L ...

Embodiment 2

[0025] Take Centella asiatica hay (the total glucoside content of Centella asiatica is 1.2%) 100kg and put into countercurrent extractor, heat 600L pure water in liquid storage tank, pure water is input instant heater with pump (pure water is heated to 95 -100°C) after heating, carry out countercurrent extraction of the Centella asiatica raw material in the extraction tank. During the extraction process, the temperature in the extraction tank is controlled at 95-100°C, extract for 90 minutes, and release the extract; add 600L of pure water to the extraction tank , carry out the second countercurrent extraction, the temperature in the extraction tank is controlled at 95-100 ° C, extract for 90 minutes, and release the extract; add 600L pure water to the extraction tank, and perform the third countercurrent extraction, the temperature in the extraction tank is controlled at 95 Extract at -100°C for 90 minutes, release the extract; combine the extracts and filter to obtain 1500 L ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com