Desulfurization and demercuration method for flue gas

A flue gas and mercury removal technology, applied in the field of environmental pollution control, can solve the problems of insignificant desulfurization effect and high regeneration cost of mercury removal by-products, and achieve the effects of good absorption effect, large specific surface area and strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

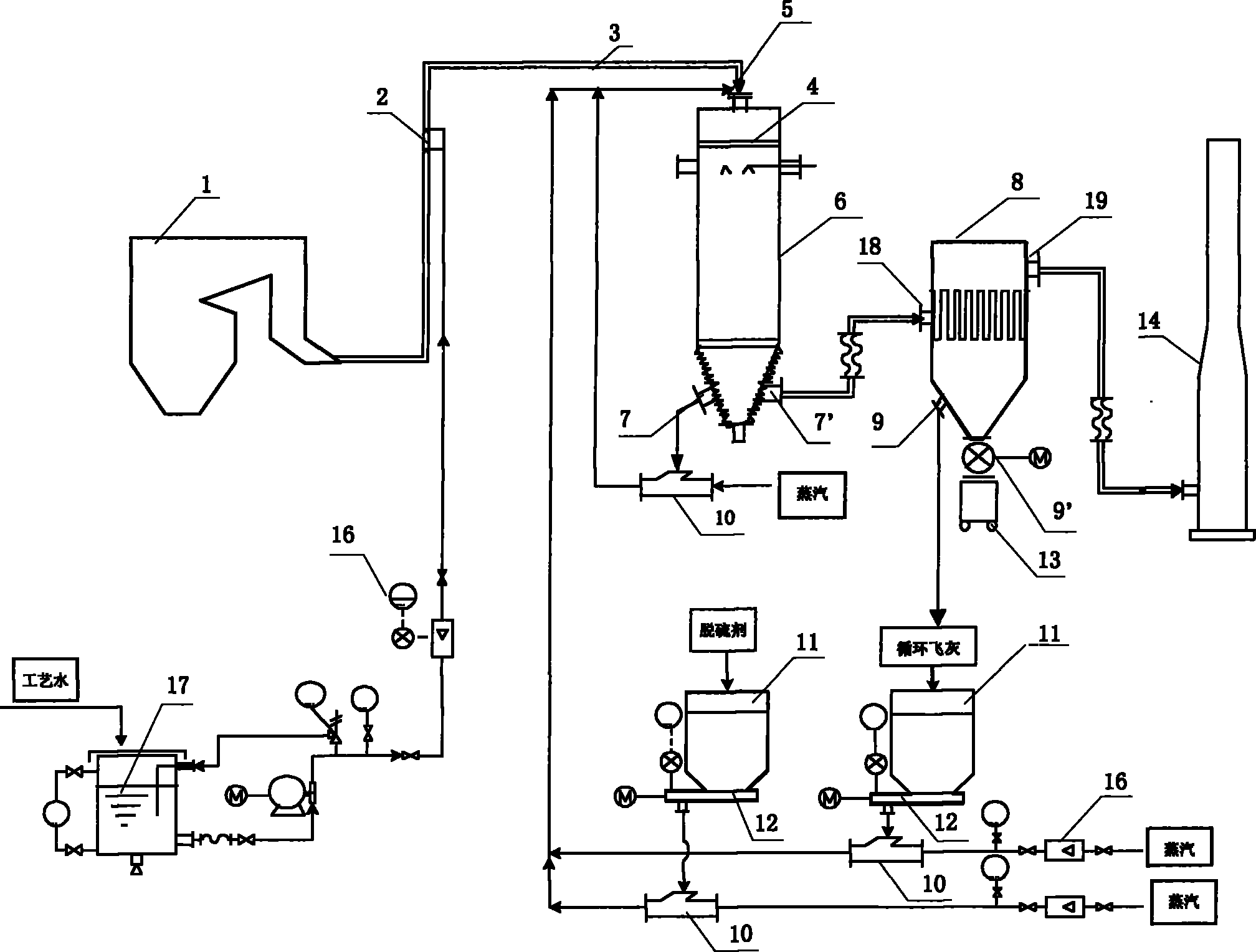

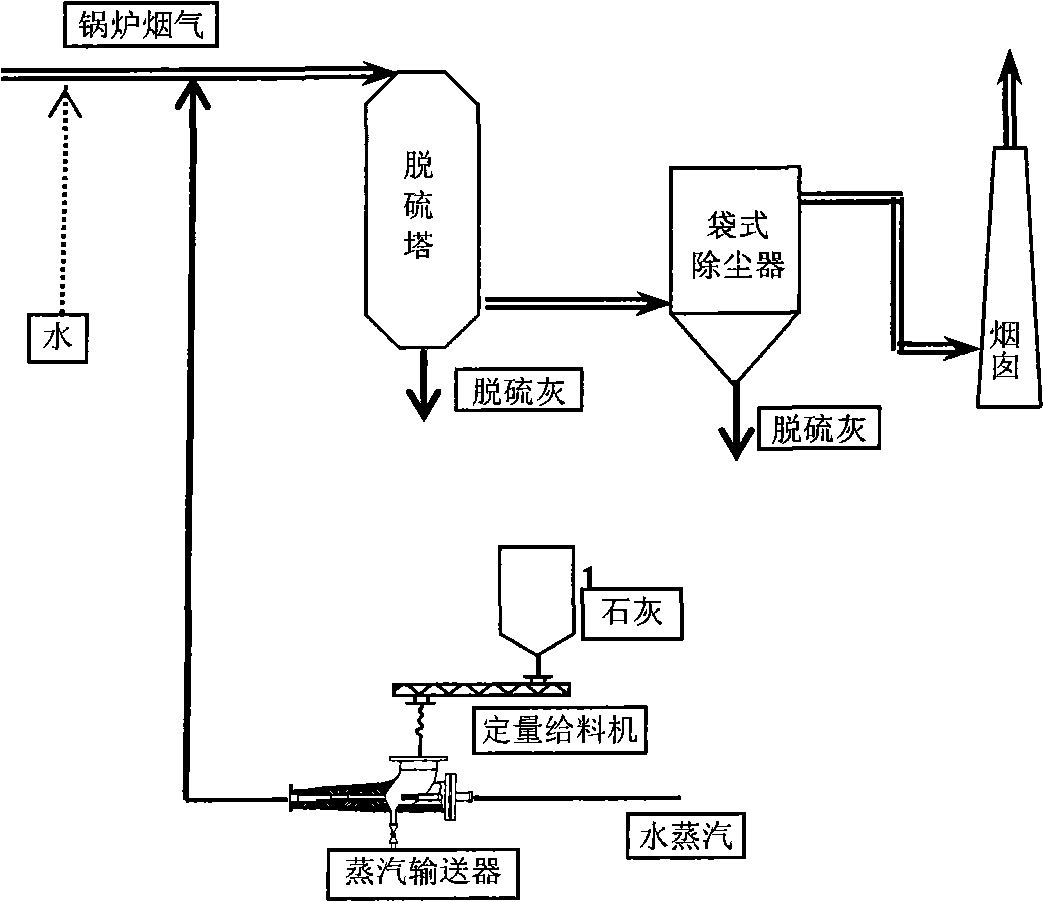

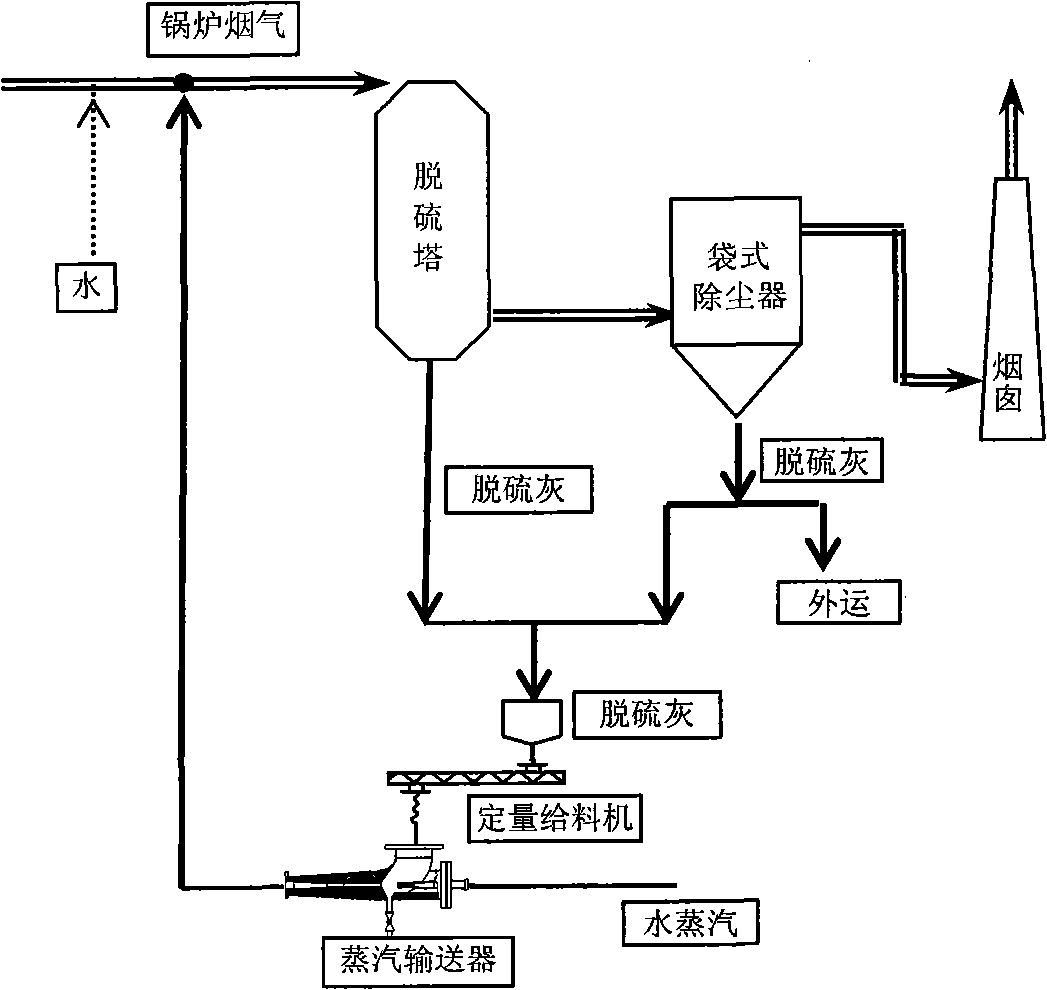

Method used

Image

Examples

Embodiment 1

[0031] A 50MW coal-fired unit boiler, the boiler load is 188t / h, the sulfur content of coal combustion is 0.5%, and the mercury content of coal combustion is 0.11mg / kg. The flue gas temperature at the outlet is 139.9°C, and the flue gas volume is 234000-236000Nm 3 / h, flue gas SO 2 The concentration is 920mg / Nm 3 . Dry flue gas desulfurization and dust removal using steam to transport desulfurizers and auxiliary desulfurizers, the temperature of the flue gas after desulfurization and dust removal is 76-79°C, and the SO 2 The concentration is 89mg / Nm 3 , using this method can remove about 98.6% of the mercury vapor in the flue gas, and the mercury content in the desulfurization ash can reach 1.58mg / kg.

[0032] The physical and chemical properties of the desulfurization ash changed significantly after steam delivery, and a part of CaO was transformed into porous Ca(OH) 2 , improve the adsorption capacity of desulfurization ash to mercury. The BET specific surface area of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com