Adhesive composition

A composition and adhesive technology, applied in the direction of adhesives, non-polymer organic compound adhesives, etc., can solve the problems of difficult resin design, inability to use water, poor environment, etc., and achieve the effect of excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

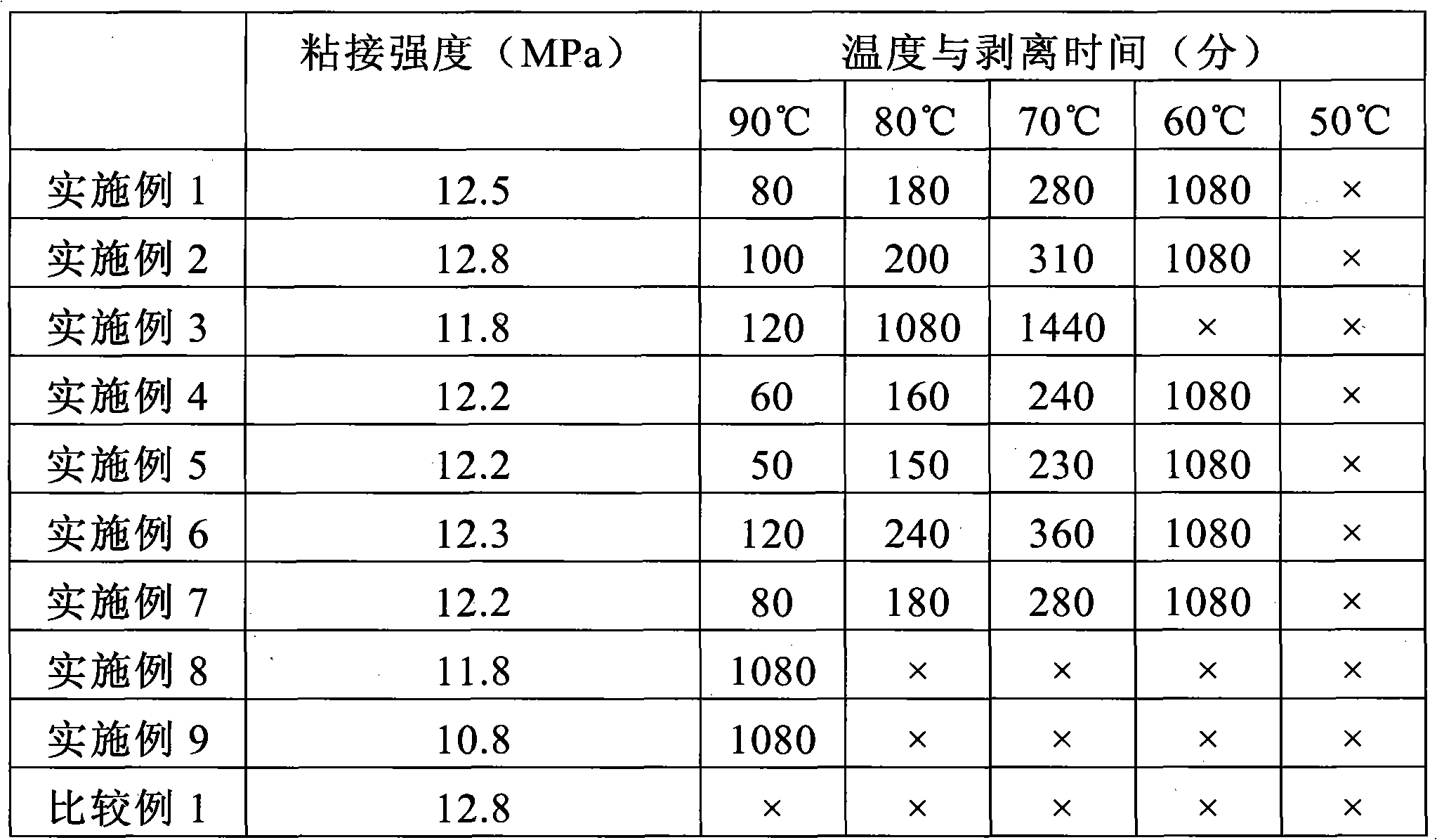

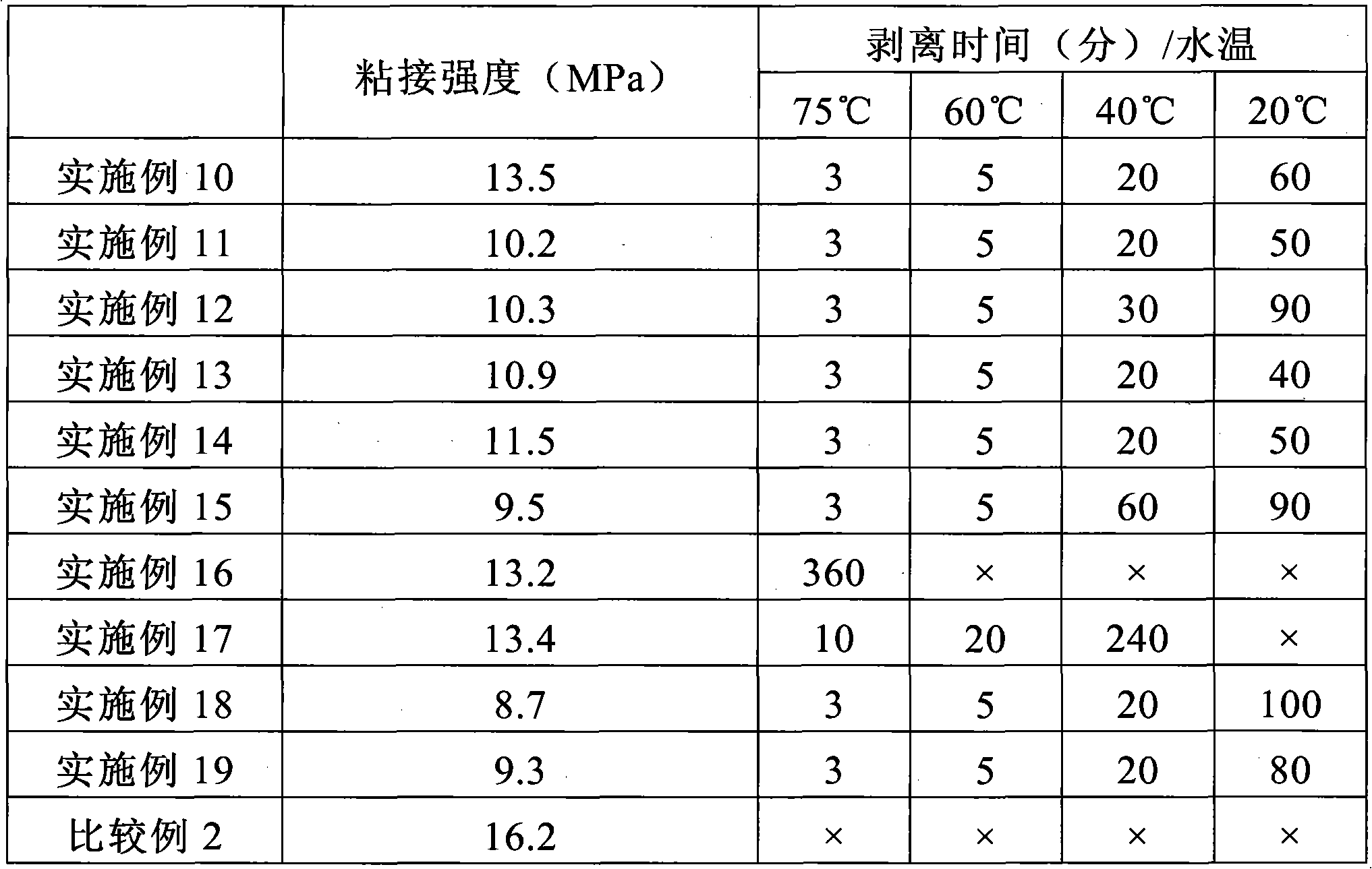

Examples

Embodiment 1

[0043] Firstly, 90 parts by weight of "jER828" (Japan Epoxy Resins (Co., Ltd.); trade name; epoxy equivalent 184-194; specific gravity 1.17; molecular weight about 370) and reactive diluent "YED216" (Japan Epoxy Resins ( Co., Ltd.); trade name; epoxy equivalent 145-165; alkyl diglycidyl ether (alkyl diglycidyl ether)) 8 parts by weight, silane coupling agent "KBM-403" (Shin-Etsu Chemical Co., Ltd.; trade name ; chemical name γ-(2,3-glycidoxy) propyltrimethoxysilane (3-glycidoxypropyltrimethoxysilane)) 2 parts by weight, and " Ecorandom (registered trademark) 1200 " (Asahi Glass (shares) Co., Ltd.); trade name; D50 is 7 to 8 μm) 100 parts by weight, and stirred for 1 hour using a mixer to uniformly mix. Secondly, "RC11" (Japan Epoxy Resins (Co., Ltd.); trade name; modified aliphatic polyamines); amine value (amine value) (from KOHmg / g to 345 to 385)) 60 parts by weight and then further stirred for 5 minutes, that is, the adhesive composition of Example 1 was produced.

Embodiment 2

[0045] Except that "Ecorandom 1200" of Example 1 was replaced with "Cellmic (registered trademark) B-819" (Sankyo Chemical Co., Ltd.; trade name; D50 is 10 μm), the same procedure was carried out as in Example 1, namely The adhesive composition of Example 2 was manufactured.

Embodiment 3

[0047] Except that "Ecorandom 1200" in Example 1 was replaced with "Cellmic 266" (Sankyo Chemical Co., Ltd.; trade name; D50 is 20 μm), the same procedure as in Example 1 was carried out, that is, the product of Example 3 was produced. Adhesive composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com