Processing method for expanding carbon fiber

A technology of carbon fiber filaments and processing methods, applied in the field of fiber processing, can solve the problems of difficulty in improving carbon fiber wettability, low shear strength and rigidity, and insufficient bulkiness of carbon fibers, etc., to achieve easy control, increase in shear strength and rigidity , the effect of high fluffiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

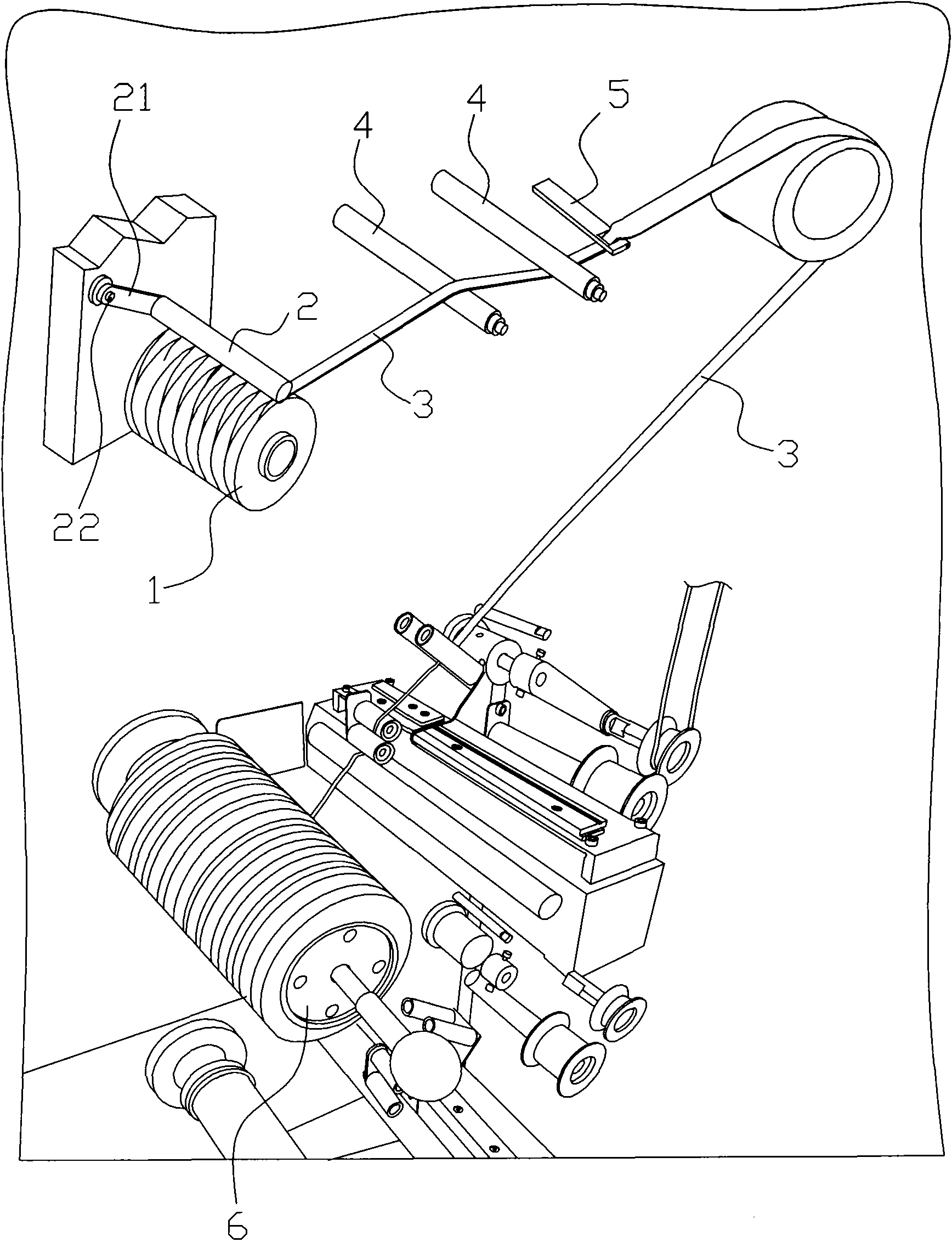

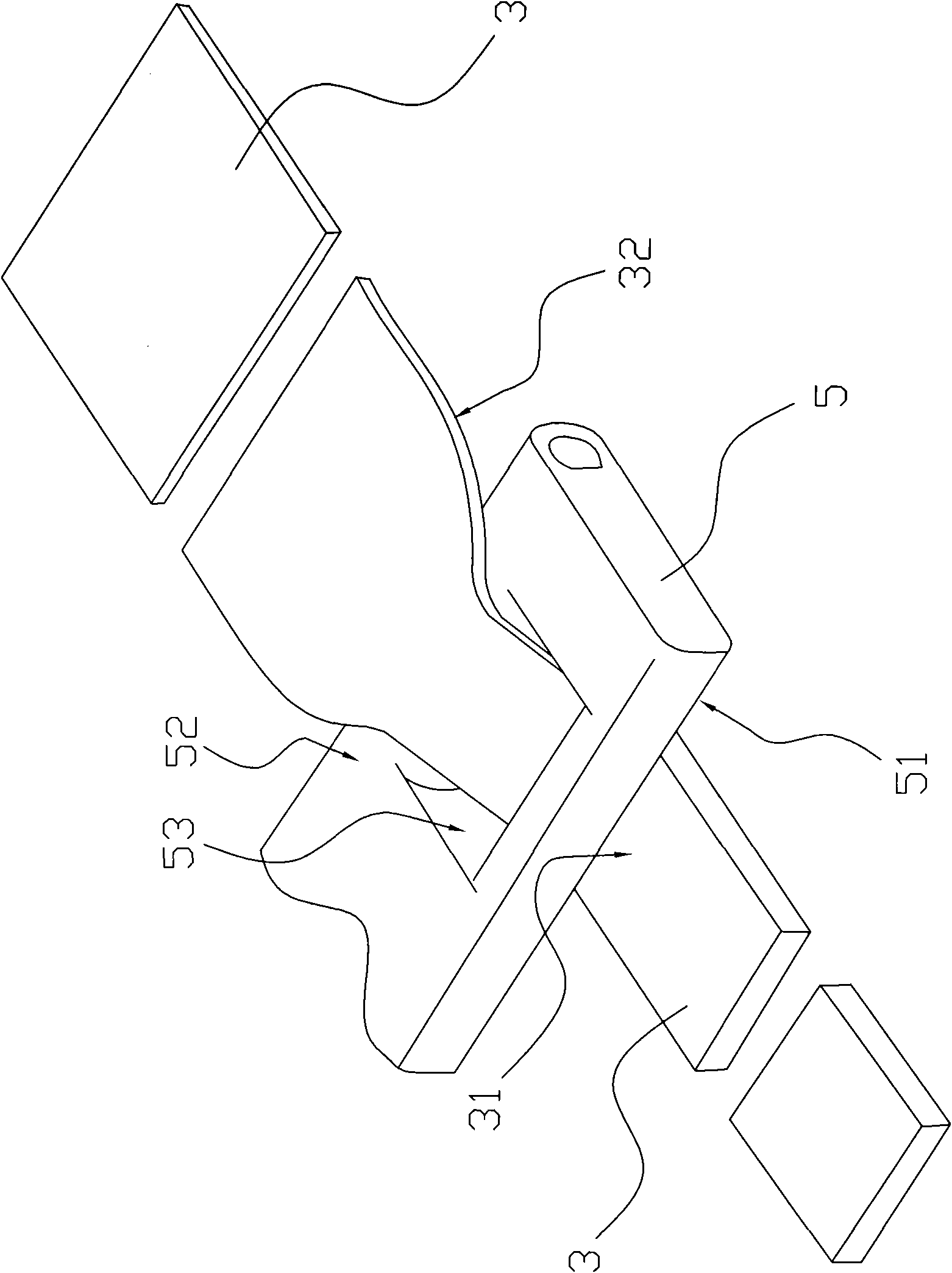

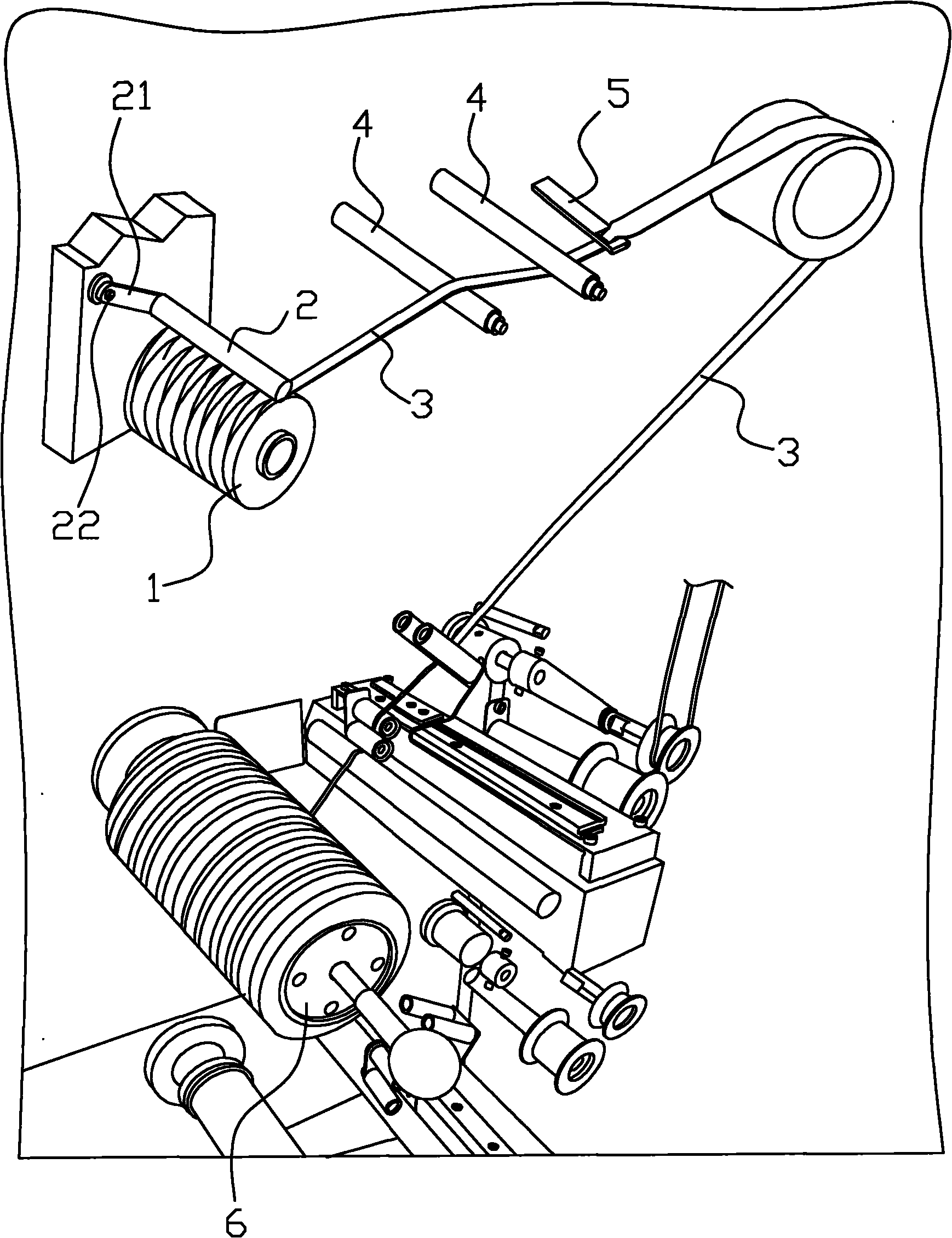

[0015] Such as figure 1 and figure 2 As shown, the expanding processing method of carbon fiber filaments in this embodiment sequentially includes the steps of stretching and stretching the carbon fiber filaments 3 wound on the unwinding reel 1, the step of heating the carbon fiber filaments, the step of widening the carbon fiber filaments, and the winding reel 6 winding step; the step of heating the carbon fiber filaments is: the carbon fiber filaments 3 unrolled on the unwinding drum 1 are wound around two charged metal rollers 4, between the two charged metal rollers 4 in this embodiment The selected voltage is 25-36 volts. A current loop is formed between the carbon fiber 3 and the two metal rollers 4. Due to the internal resistance of the carbon fiber 3, the carbon fiber 3 generates heat to soften the resin on the surface of the carbon ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap