Method for producing reinforced carbon nano pipeline adopting fiber yarns as carriers

A carbon nanotube, carbon nanotube technology, which is applied to conductive layers on insulating carriers, fiber processing, textiles and papermaking, etc., can solve the problems of fracture, slow carbon nanotubes, and insufficient strength of carbon nanotubes. Effects of ergonomics, good electrical conductivity, high tensile strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

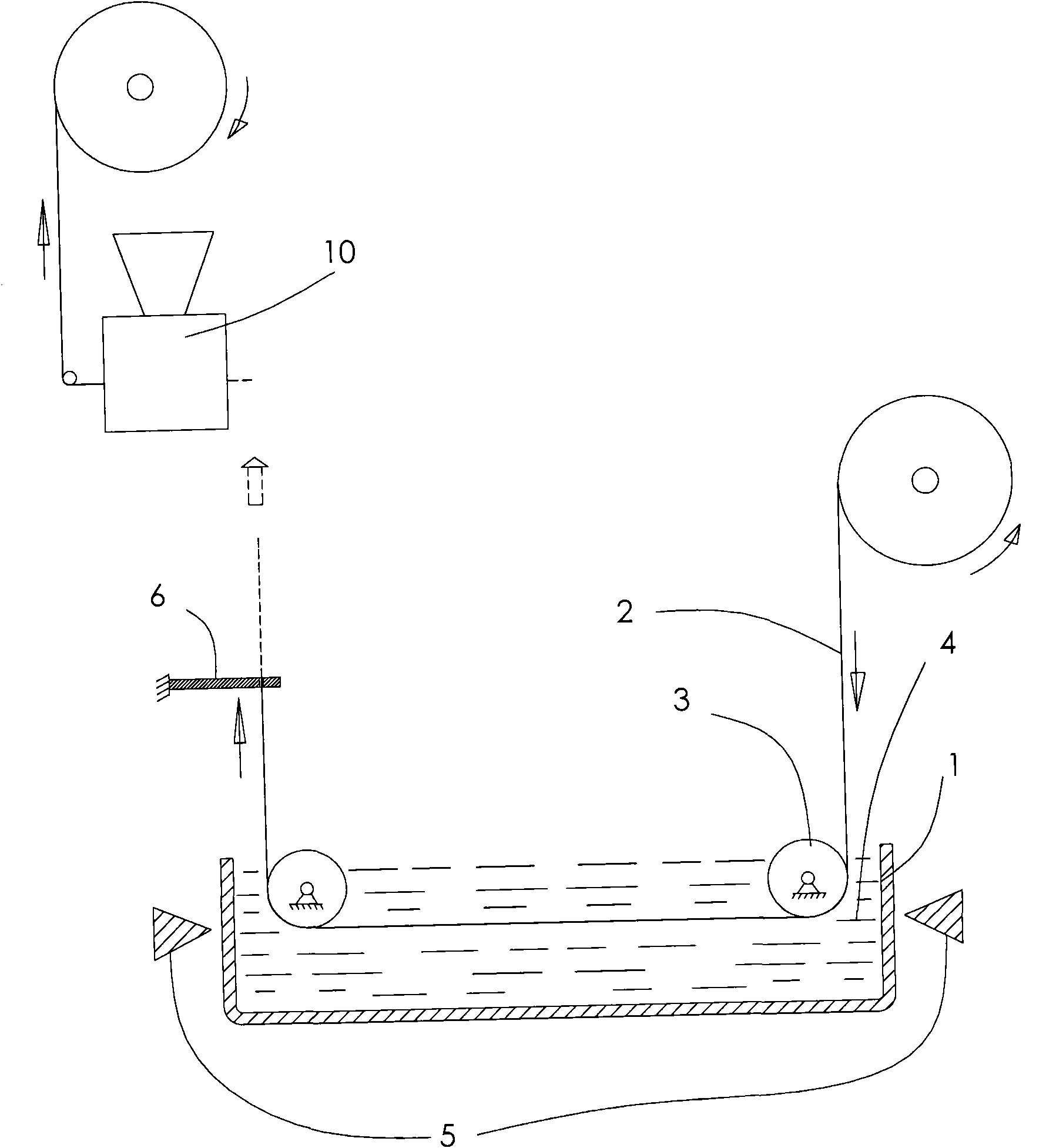

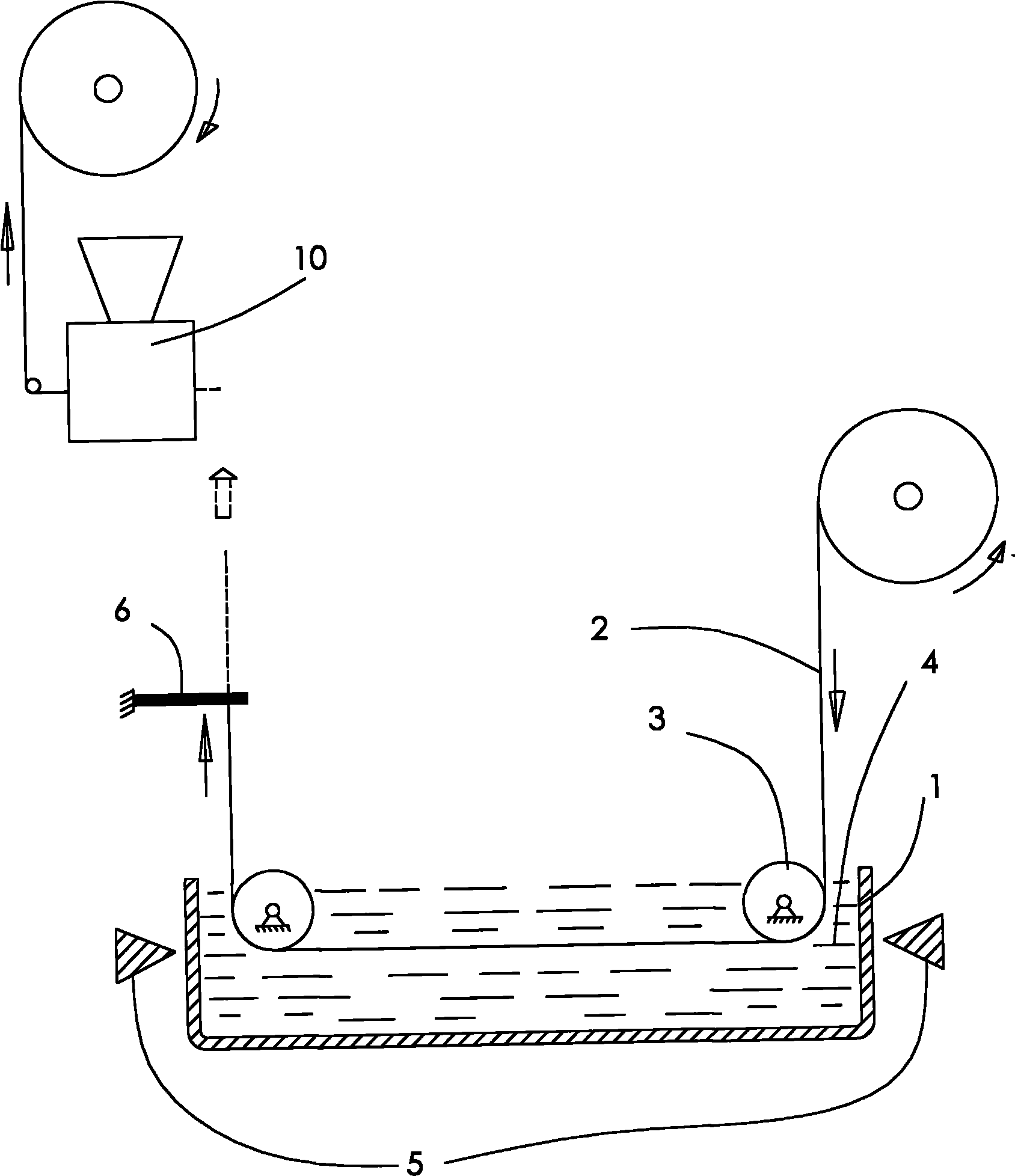

[0024] The manufacturing device of the present invention such as figure 1 As shown, it mainly includes a container 1, a single or multi-strand fiber line 2, a guide wheel 3, a filter plate 6 and a tooling 10 for wrapping polymer wires. A carbon nanotube suspension 4 is built in the container 1, and a tapered pole 5 forming an uneven electric field is placed outside the container 1; the fiber wire 2 is wound on the wire wheel 3 and placed in the carbon nanotube suspension 4 in the container 1 ; The fiber line 2 is parallel to the central axis formed by the tapered poles 5 ; the container 1 , the wire wheel 3 , the filter plate 6 and the polymer wire plastic-coated tooling 10 are arranged in sequence.

[0025] Before manufacturing the carbon nanotube wire of the present invention, in the container 1, the carbon nanotube is dissolved in an organic solv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com