Embedded numerically controlled drill lathe control system and work method

An embedded numerical control and control system technology, applied in the direction of digital control, electrical program control, etc., can solve the problems of inability to meet the multi-functional and open requirements of drilling machines, insufficient utilization of PC resources, and unreasonable structure of the control system. , to achieve the effects of easy maintenance and expansion, improved portability, and clear functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

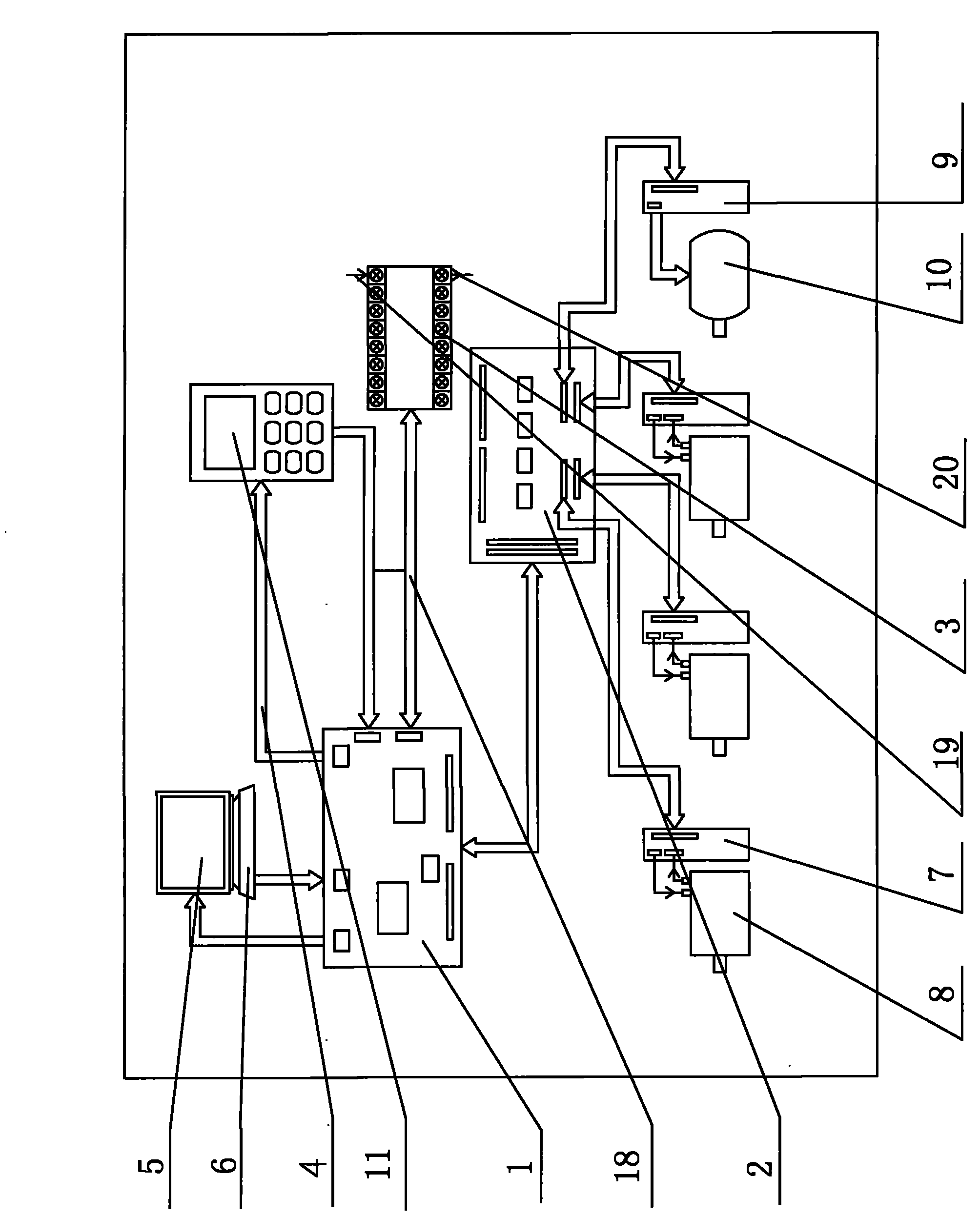

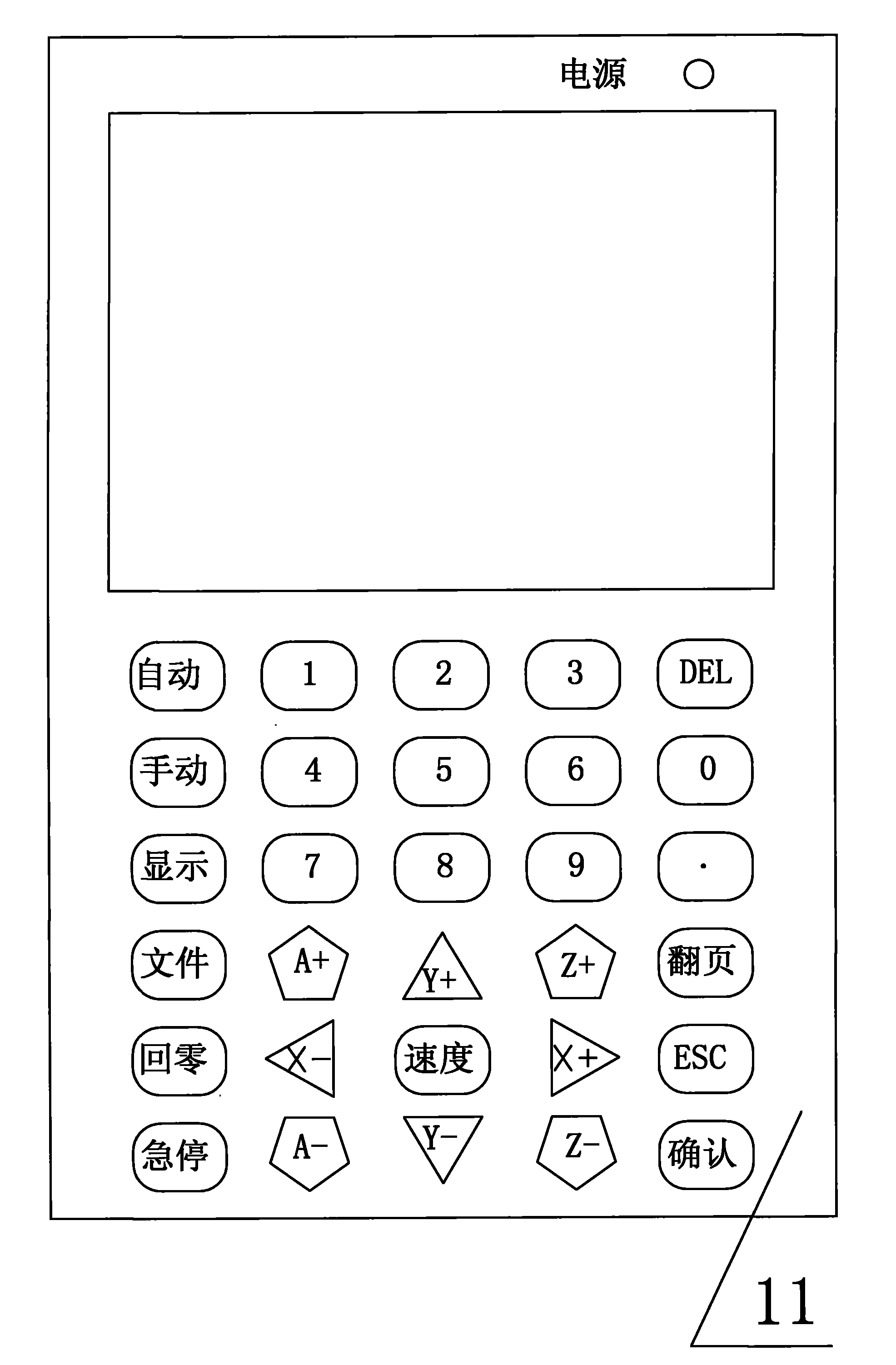

[0020] Embedded CNC drilling machine control system, its composition includes: Gugao embedded motion controller 1, the model of Gugao embedded motion controller 1 is GU-400-EPG-102\128-G, and it is connected to the external terminal board 2 at the same time , single-chip PLC3, interface VGA4 and display 5, described display 5 connects keyboard 6, described external terminal board 2 connects servo motor 8 by servo driver 7, described external terminal board 2 connects drill bit motor 10 by frequency converter 9 , the interface VGA4 is connected to the teaching box 11 .

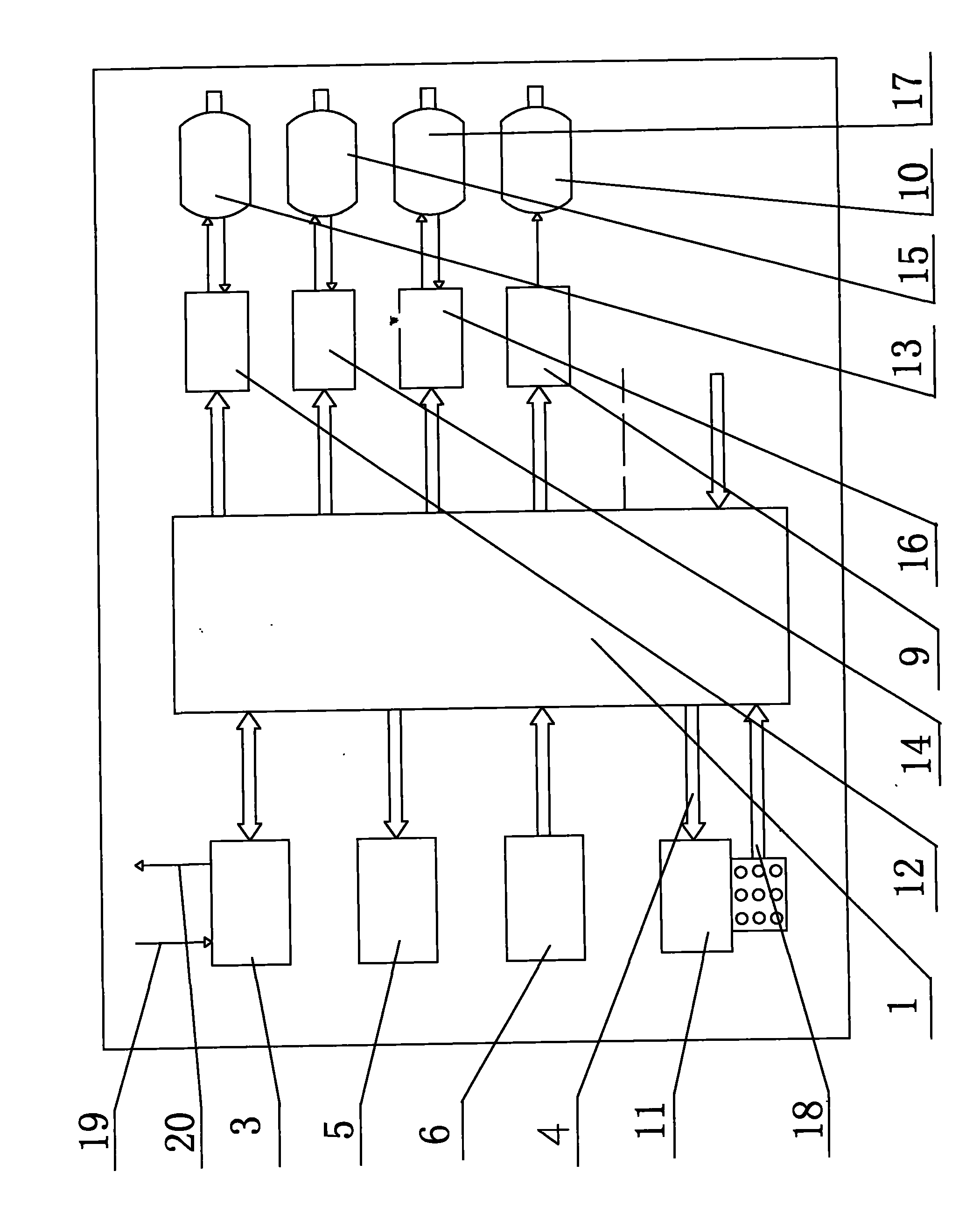

[0021] In the embedded CNC drilling machine control system, the solid high embedded motion controller 1 model GU-400-EPG-102\128-G is connected to the X-axis servo motor 13 through the X-axis servo driver 12, and the solid-state The high embedded motion controller model is 1GU-400-EPG-102\128-G, which is connected to the Y axis servo motor 15 through the Y axis servo driver 14, and the model of the solid high e...

Embodiment 2

[0025] The working method of the embedded numerical control drilling machine control system described in embodiment 1:

[0026] Described numerical control system software, human-computer interaction interface, teaching box driver are all developed on the Win CE operating system platform with Visual c++6.0 programming software in conjunction with Microsoft's MFC class library; Control system human-computer interaction interface includes status display , parameter setting, file management, editing graphics, automatic, manual and diagnostic functions.

Embodiment 3

[0028] A working method of an embedded numerical control drilling machine control system,

[0029] The model of the Gugo embedded motion controller is GU-400-EPG-102\128-G, which controls the X-axis, Y-axis and Z-axis servo motors of the drilling machine in pulse mode, so as to realize the accurate positioning of the drilling machine position. Servo motor works in position mode; Googo embedded motion controller simultaneously controls the frequency converter by sending analog quantity, so as to control the rotation speed of the drill bit; the single-chip PLC is mainly responsible for the control of I / O points, such as the opening of the cold shower, etc. ; Googo's embedded motion controller communicates with the single-chip PLC and the teaching box through RS232, so that all motion control inputs can be completed by the host computer interface and the teaching box, and the processing process can be monitored in real time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com