Embedded control system for carton proofing machine and control method thereof

An embedded control and proofing machine technology, applied in the direction of digital control, electrical program control, etc., can solve the problem of not being able to build an embedded motion control platform, size, cost and operating environment constraints, difficulty in independent operation and miniaturization, etc. problems, to achieve the effect of easy software development, good reliability and scalability, real-time performance and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

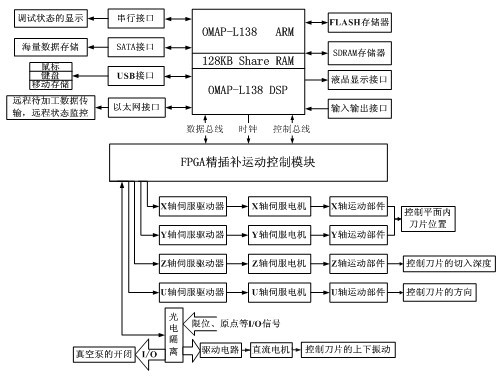

[0027] Such as figure 1 As shown, the hardware structure includes the OMAP-L138 main chip and its surrounding peripherals, as well as the pulse output control and I / O control of FPGA.

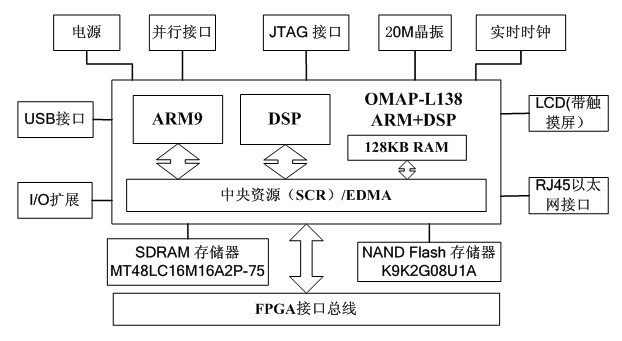

[0028] Such as figure 2 As shown, the peripherals around the OMAP-L138 main chip include NAND Flash memory, SDRAM memory, RJ45 Ethernet interface, LCD, real-time clock, 20M crystal oscillator, JTAG interface, parallel interface, USB interface, I / O expansion, etc.

[0029] The main control board is based on the embedded processor OMAP-L138, which integrates ARM9 and DSP cores. The main task of the ARM part of the processor OMAP-L138 is to realize carton graphics data processing, conversion and compilation of carton NC processing codes, trajectory planning, speed preprocessing calculation, man-machine interface and other tasks, and the DSP part is mainly respon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com