Equipment for removing carbon dioxide from waste gas

A carbon dioxide and exhaust gas technology, applied in the direction of chemical separation, air quality improvement, chemical instruments and methods, etc., can solve the problems of low carbon dioxide removal efficiency, poor biological adaptability, etc., achieve long service life, strong applicability, and reduce membrane fouling the degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

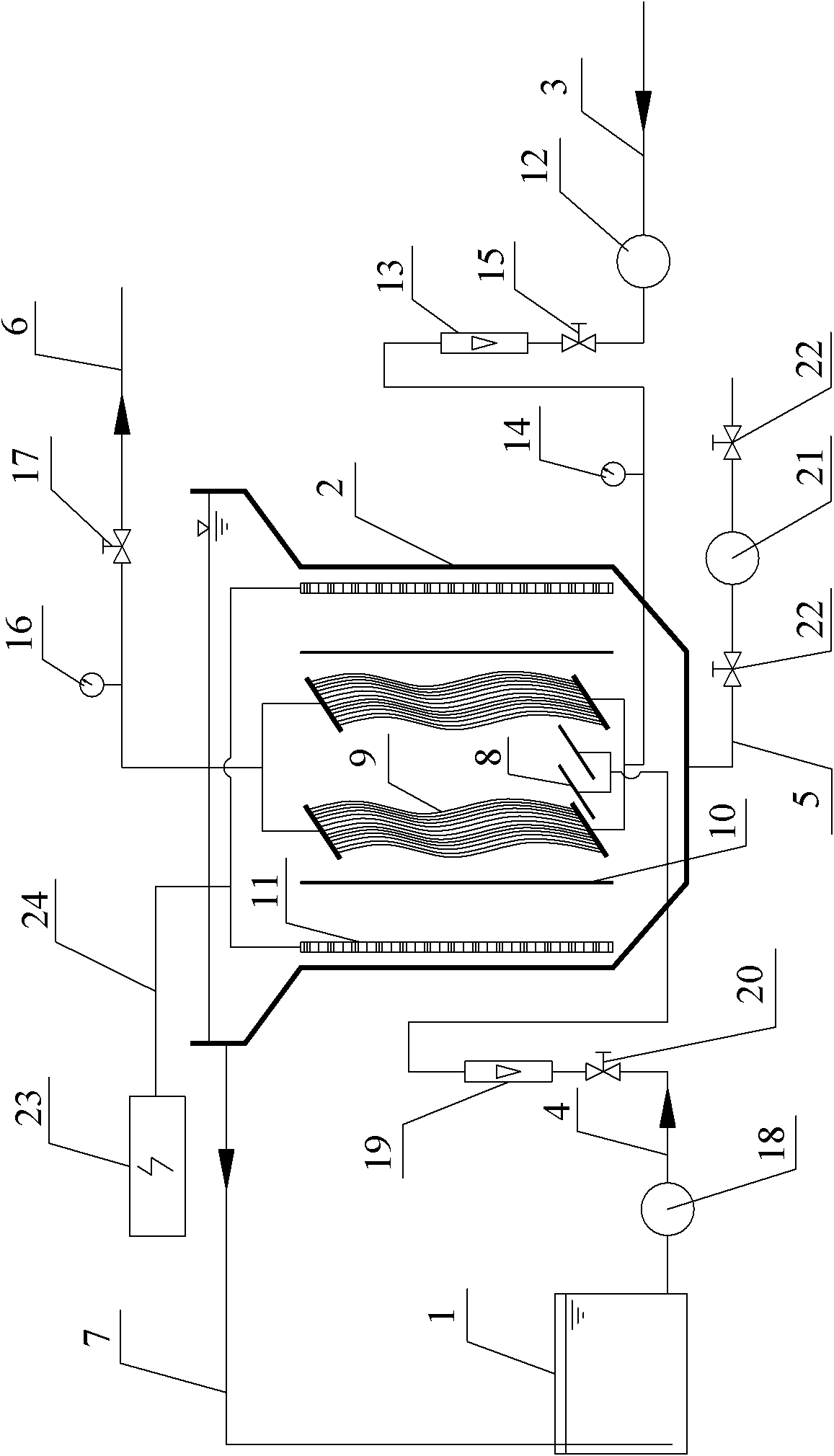

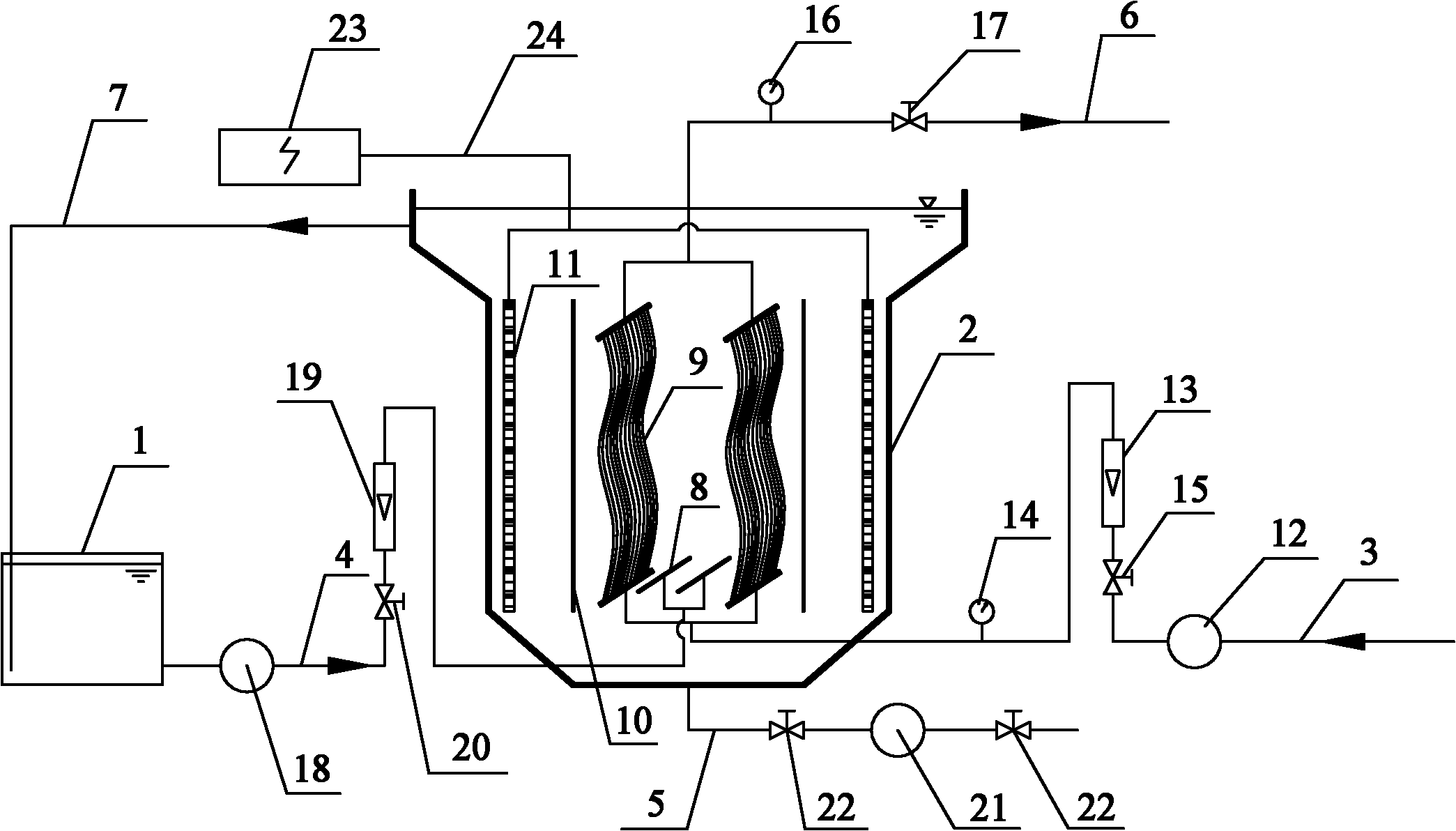

[0030] Such as figure 1 Shown, the present invention comprises algae cultivation water tank 1 and the purification reaction container 2 that is connected with algae cultivation water tank 1, the bottom of described purification reaction container 2 is provided with inlet pipe 3, water inlet pipe 4 and mud discharge pipe 5, and described purification The top of the reaction vessel 2 is provided with an air outlet pipe 6 and a water outlet pipe 7, and the purification reaction vessel 2 is sequentially provided with a water distributor 8, a hollow fiber membrane module 9, a baffle plate 10 and a light source 11 from the inside to the outside; The inlet pipe 3 communicates with the bottom of the hollow fiber membrane module 9 and an inlet pump 12, a gas flow meter 13, an inlet pressure gauge 14 and an inlet valve 15 are installed on the inlet pipe 3; The top of the fiber membrane assembly 9 is connected and is equipped with an outlet pressure gauge 16 and an outlet valve 17 on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com