Low-temperature carbonitriding catalyst and carbonitriding method thereof

A technology of carbonitriding and process method is applied in the field of iron and steel metallurgy treatment, and achieves the effects of low preparation temperature, saving industrialized production, and easy control of process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

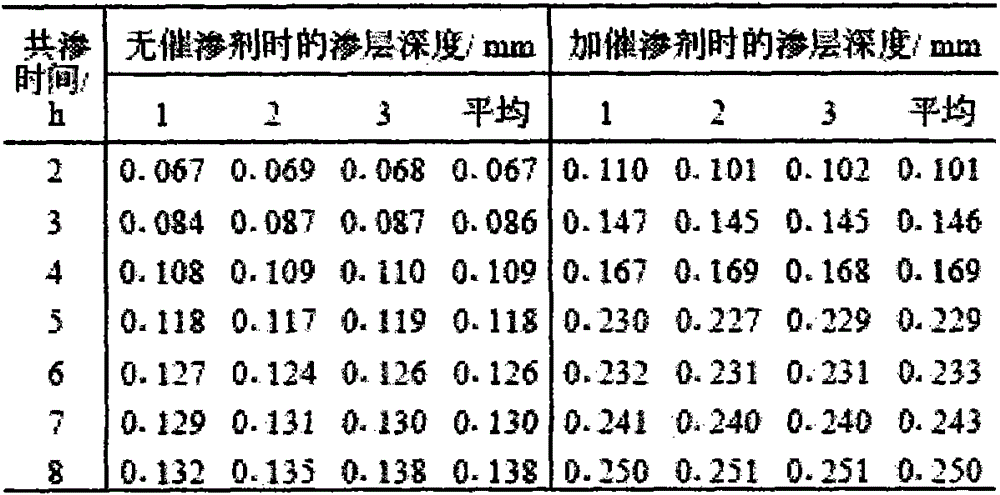

Embodiment 1

[0040]Using ammonium chloride, sponge titanium, rare earth, solid chromate, aluminum powder and quartz sand as raw materials, weigh each raw material in proportion, grind and mix them uniformly to form a catalyst, wherein the catalyst includes 10.6% by weight of chlorine ammonium chloride, 1.8% titanium sponge, 9% rare earth, 0.1% solid chromate, 0.01% aluminum powder, and the rest of the catalyst is quartz sand.

[0041] Mix the catalyst evenly and put it in a stainless steel container with the cleaned 3Cr2W8V steel test workpiece according to the specific gravity of 250:1 and put them into the bottom of the carburizing furnace for composite co-carburizing. It is carried out in the furnace, and the temperature control device is an electronic potentiometer. The test temperature is 500°C, and the test time is (2-8) h. The osmotic agent is [(NH2)2CO+C2H5OH] saturated solution + kerosene, and the amount of osmotic agent added is (70-80) drops / min. Finally, the product was coole...

Embodiment 2

[0047] Using ammonium chloride, sponge titanium, rare earth, solid chromate, aluminum powder and quartz sand as raw materials, weigh each raw material in proportion, grind and mix them uniformly to form a catalyst, wherein the catalyst includes 12% by weight of chlorine ammonium chloride, 2.5% titanium sponge, 10% rare earth, 1% solid chromate, 0.015% aluminum powder, and the rest of the catalyst is quartz sand.

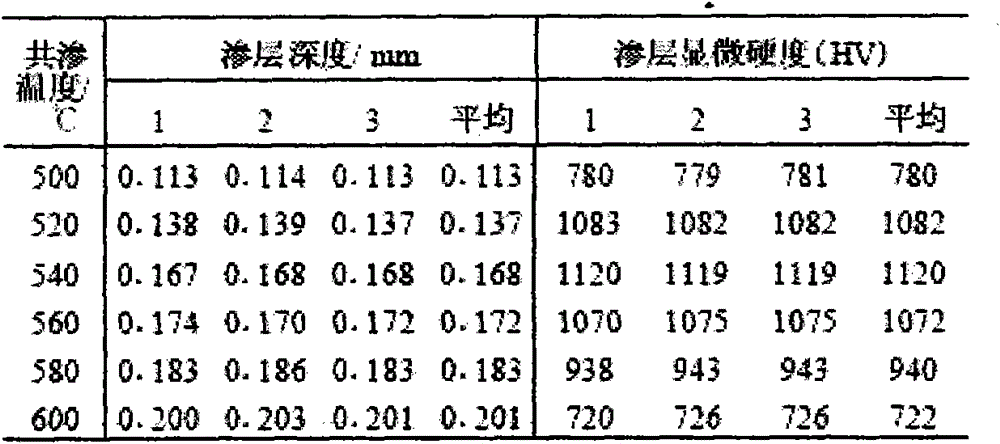

[0048] Mix the catalyst evenly and put it in a stainless steel container with the cleaned 3Cr2W8V steel test workpiece according to the specific gravity of 250:1 and put them into the bottom of the carburizing furnace for composite co-carburizing. It is carried out in the furnace, and the temperature control device is an electronic potentiometer. The test temperature is 500-600°C, and the co-infiltration time is 4 hours. The osmotic agent is [(NH2)2CO+C2H5OH] saturated solution + kerosene, and the amount of osmotic agent added is (70-80) drops / min. Finally, the pro...

Embodiment 3

[0053] Using ammonium chloride, sponge titanium, rare earth, solid chromate, aluminum powder and quartz sand as raw materials, weigh each raw material in proportion, grind and mix them uniformly to form a catalyst, wherein the catalyst includes 10.6% by weight of chlorine ammonium chloride, 1.8% titanium sponge, 9% rare earth, 0.1% solid chromate, 0.01% aluminum powder, and the rest of the catalyst is quartz sand.

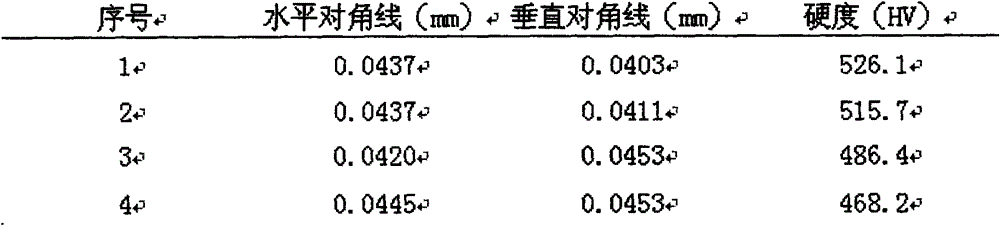

[0054] Mix the catalyst evenly and put it in a stainless steel container with the cleaned 20CrMnTi test workpiece according to the specific gravity of 250:1 and put it into the bottom of the carburizing furnace for composite co-carburizing. The temperature control device is an electronic potentiometer. The test temperature is 540°C, and the co-infiltration time is 4 hours. The osmotic agent is [(NH2)2CO+C2H5OH] saturated solution + kerosene, and the amount of osmotic agent added is (70-80) drops / min. Finally, the product was cooled to room temperature to complete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com