Thermomechanical treatment method for obtaining high-strength and high-toughness magnesium alloy

A deformation heat treatment and magnesium alloy technology, applied in the field of artificial aging treatment to prepare high-strength, high-toughness magnesium alloys, and deformation heat treatment fields, can solve the problems of affecting the processing ability, poor room temperature plasticity, reduced ductility of magnesium alloys, etc., to improve the strength and equipment. Requires simple, ductile effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

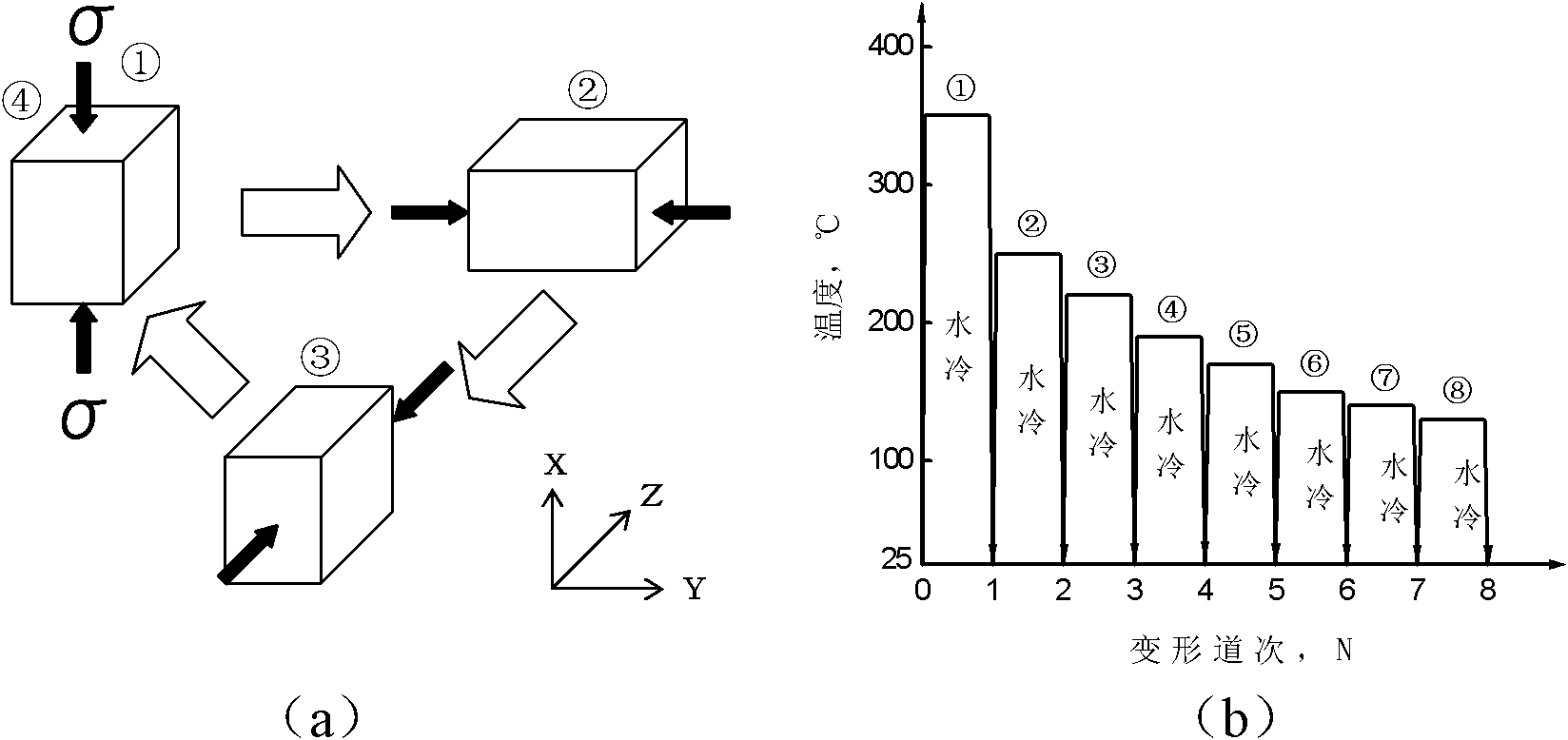

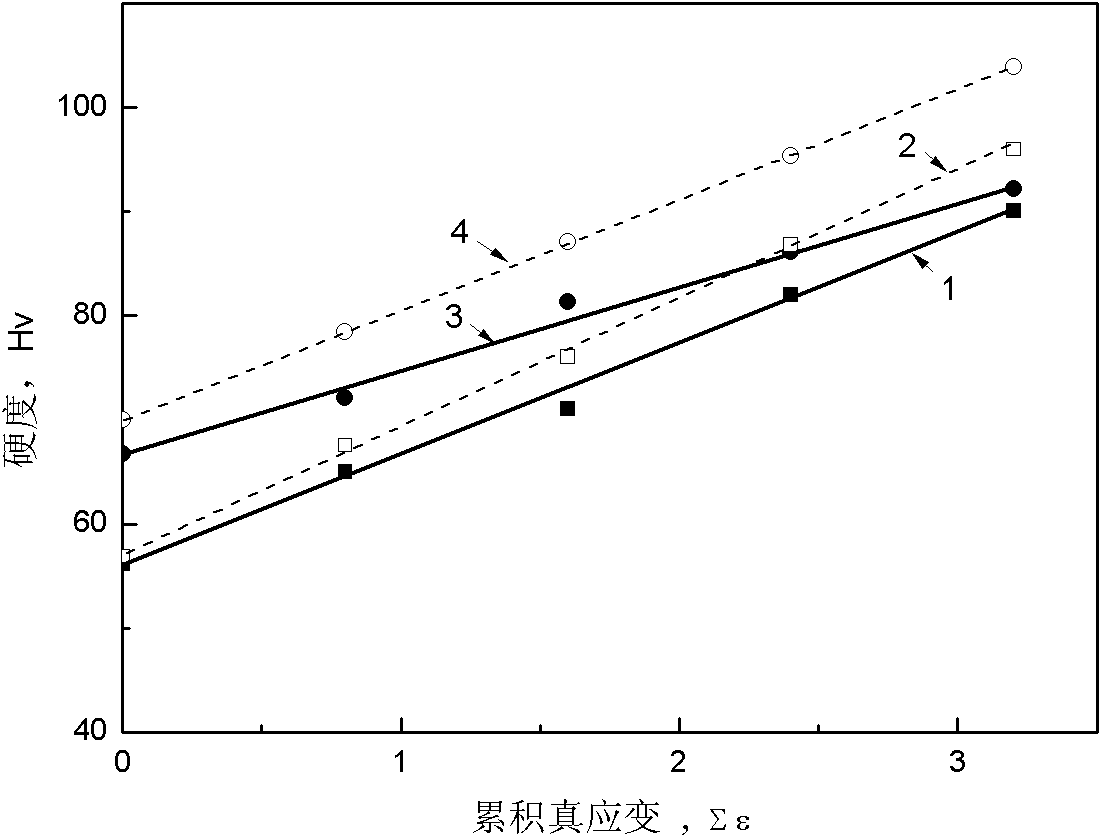

Embodiment 1

[0043] Cut the AZ91 magnesium alloy ingot into rectangular blocks, place it in the furnace, heat it to 400°C for 12 hours, and then quench it with water. After holding it at 380°C for 8 minutes, place the test piece on the lower flat anvil of the hydraulic press, with the X axis as the The compression shaft undergoes compression deformation with a strain rate of 10 -3 the s -1 ; When the true strain in the X direction reaches 0.4, stop the compression and take out the test piece for water quenching, then keep it warm at 260°C for 8 minutes, rotate the test piece 90 degrees, take the Y axis as the compression axis, and compress again. When the true strain reaches 0.4, stop the compression and take out the specimen for water quenching, then keep it warm at 240°C for 8 minutes, rotate the specimen by 90 degrees, and compress again with the Z axis as the compression axis. When the true strain in the Z direction reaches 0.4, stop the compression and take out the specimen for water...

Embodiment 2

[0045] Cut AZ61 magnesium alloy extruded rods into rectangular blocks, heat them in the furnace to 450°C for 2 hours, then water quench and cool them. The axis is the compression axis for compression deformation, and the strain rate is 10 -3 the s -1 ; When the true strain in the X direction reaches 1, stop the compression and take out the specimen for water quenching, then keep it warm at 250°C for 8 minutes, rotate the specimen by 90 degrees, take the Y axis as the compression axis, and compress again. When the true strain in the Y direction reaches 1, stop the compression and take out the specimen for water quenching, then keep it warm at 220°C for 8 minutes, rotate the specimen 90 degrees, and compress it again with the Z axis as the compression axis. When the true strain in the Z direction reaches 1, stop the compression and take out the specimen for water quenching, then keep it warm at 190°C for 8 minutes, rotate the specimen 90 degrees, and take the X axis as the comp...

Embodiment 3

[0047] Cut AZ61 magnesium alloy extruded rods into rectangular blocks, place them in a furnace, heat them to 460°C for 1.5 hours, then water quench and cool them. The axis is the compression axis for compression deformation, and the strain rate is 10 -2 the s -1 ; When the true strain in the X direction reaches 0.8, stop the compression and take out the specimen for water quenching, then keep it warm at 250°C for 8 minutes, rotate the specimen 90 degrees, and compress it again with the Y axis as the compression axis. When the true strain in the Y direction reaches 0.8, stop the compression and take out the specimen for water quenching, then keep it warm at 220°C for 8 minutes, rotate the specimen by 90 degrees, take the Z axis as the compression axis, and compress again. When the true strain in the Z direction reaches 0.8, stop the compression and take out the specimen for water quenching, then keep it warm at 190°C for 8 minutes, rotate the specimen 90 degrees, and take the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com