Method for preparing natural cellulose nonwoven fabric in wet-type meltblown mode

A natural cellulose and cellulose technology, applied in the direction of single-component cellulose rayon, wet spinning, non-woven fabrics, etc., can solve the problems of high cost, high cost, adverse impact on the environment, etc., and achieve manufacturing cost The effect of reducing and shortening the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

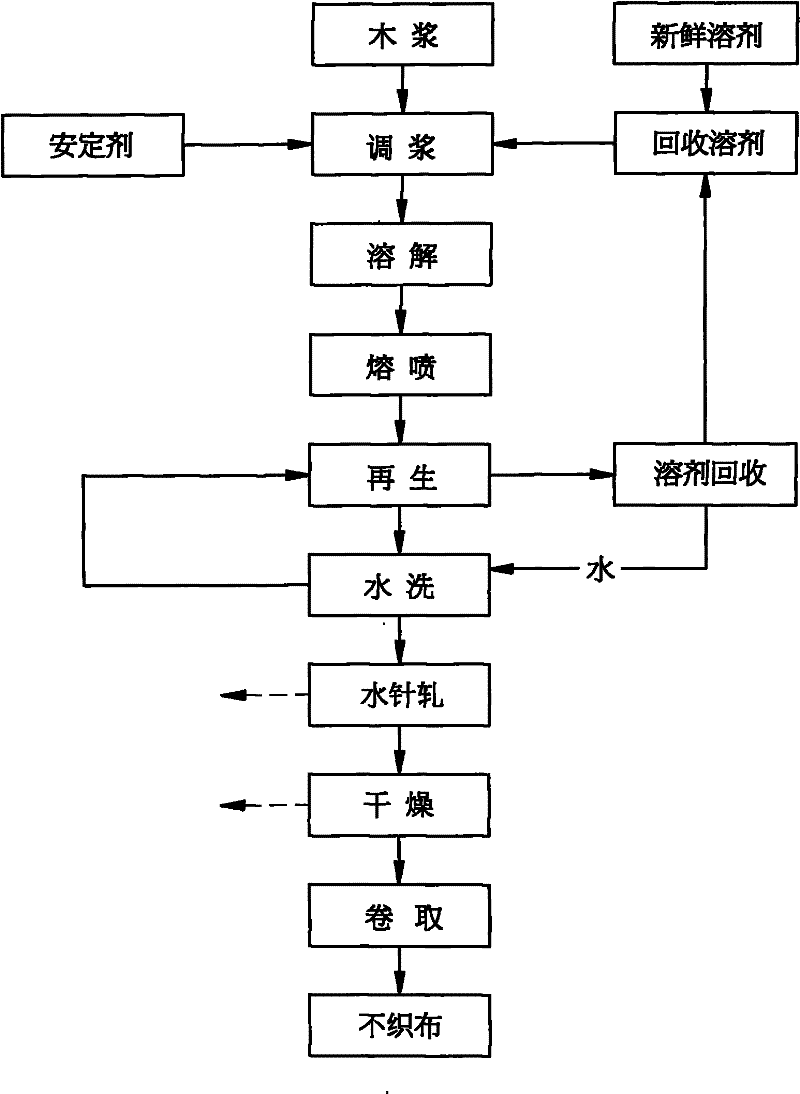

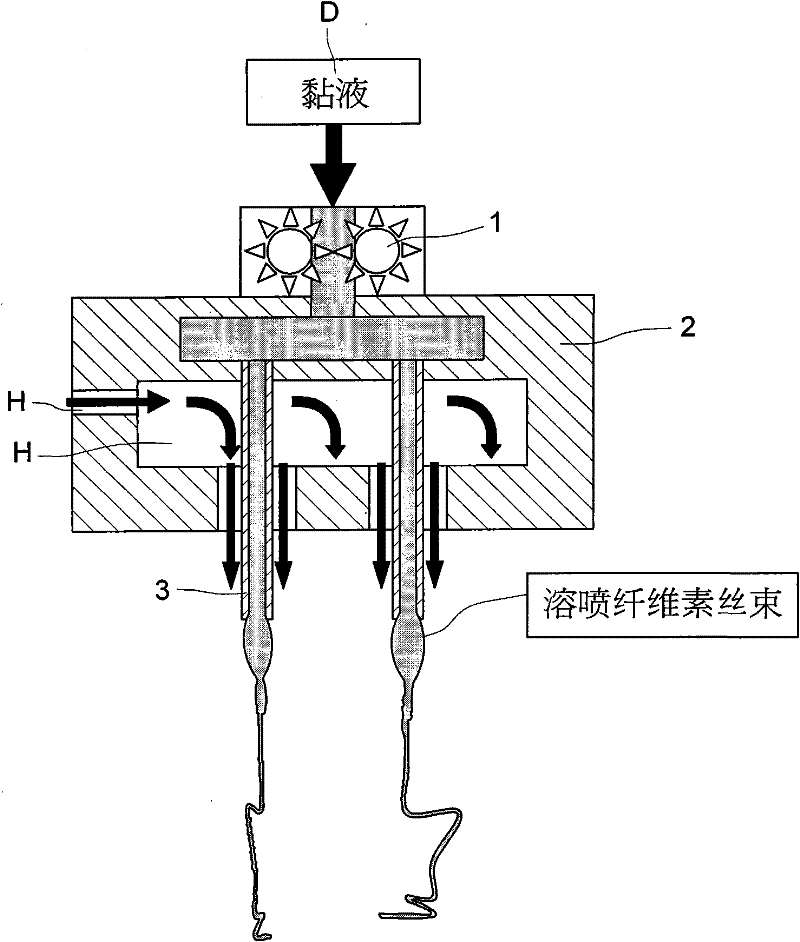

[0030] see Figure 1 to Figure 5 Shown, the present invention uses the method for the preparation of natural cellulose nonwoven fabric of wet type melt-blown mode, and its steps comprise:

[0031] a. Use wood pulp (pulp) as raw material; select long and short fiber wood pulp cellulose with an α-cellulose content of more than 65%, and its cellulose degree of polymerization (DP for short) is between 500 and 1200 ;

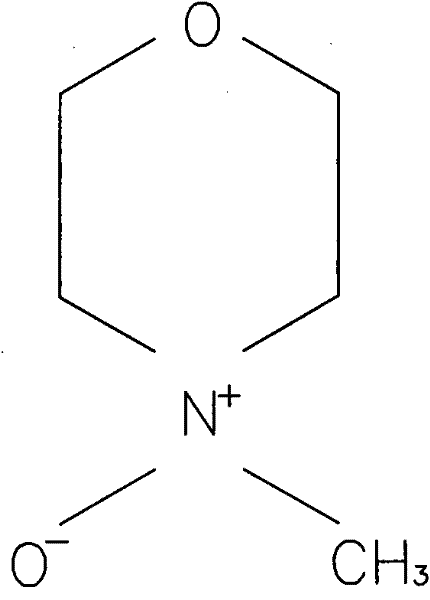

[0032] b. Add methylmorpholine N-oxide (N-methylmorpholine N-oxide, NMMO for short, its chemical structure is as follows figure 2 Shown) and phenyl oxazoline (1,3-phenylene-bis 2-oxazoline, BOX) in wood pulp, make it mix and dissolve into mucus (dope); After the wood pulp cellulose, oxidized methyl marin solvent and phenyloxazole additive are placed together, they are crushed at a high speed at a low temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Base weigh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com