Formation pressure measuring device while drilling

A technology of formation pressure and measuring device, applied in the field of oil drilling, can solve the problems of prolonged drilling operation time and increased drilling cost, and achieve the goal of optimizing drilling fluid density and equivalent circulating density, reducing operation risk and drilling cost, and improving prediction accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The implementation of the present invention will be described below in conjunction with the accompanying drawings.

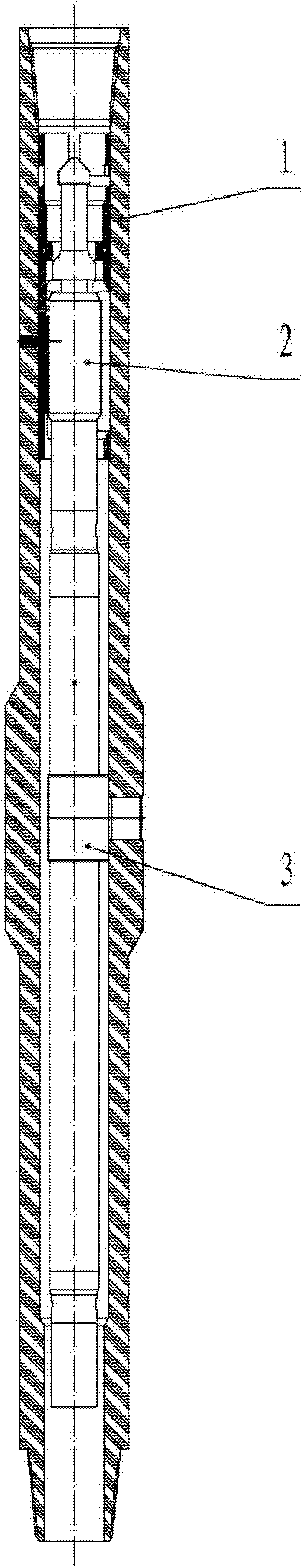

[0015] Such as figure 1 As shown, the formation pressure measurement device while drilling generally includes a measurement drill collar 1 , a mud pulse generator assembly 2 and a formation pressure measurement assembly 3 .

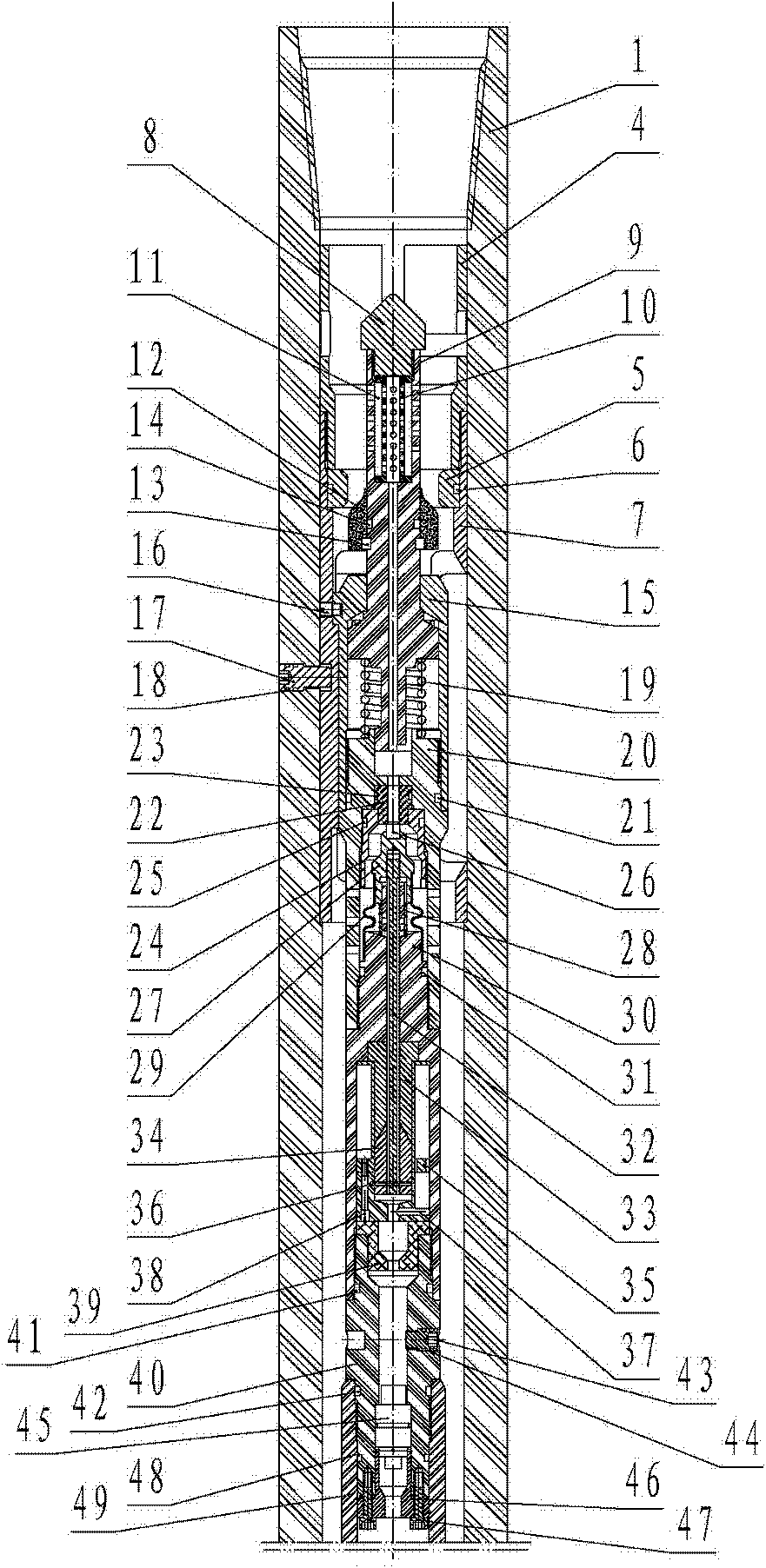

[0016] Such as figure 2 As shown, the mud pulse generator assembly 2 is composed of the main valve outer ring pressure sleeve 4, the main valve outer ring 5, the outer ring sealing ring 6, the directional inner sleeve 7, the pressure guiding piston rod cap 8, the main valve pressure guiding piston rod 9. Filter skeleton 10, filter screen 11, main valve inner ring 12, main valve semi-circular key 13, main valve inner ring sealing ring 14, main valve piston barrel 15, anti-rotation bolt 16, directional bolt 17, directional bolt Sealing ring 18, main valve spring 19, servo valve outer cylinder 20, servo valve outer cylinder sealing r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com