Micro-mechanical CMOS (complementary metal oxide semiconductor) thermopile infrared temperature sensor

An infrared temperature measurement and thermopile technology, applied in electrical radiation detectors, piezoelectric devices/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, etc., can solve the difficulty of protecting wet corrosion substrates It is difficult to guarantee the controllability of corrosion, and the cost of SOI substrates is high, so as to improve the efficiency of infrared utilization, the controllability of the method is excellent, and it is not easy to be damaged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

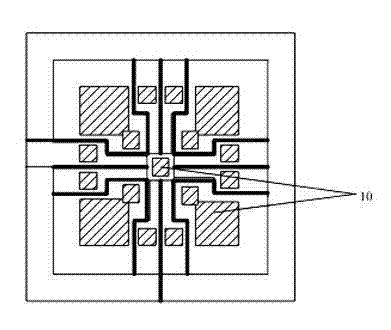

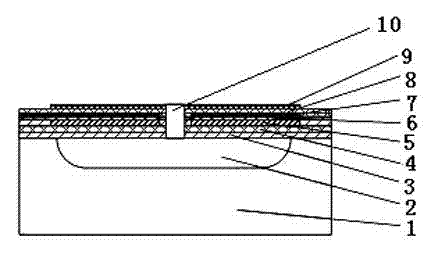

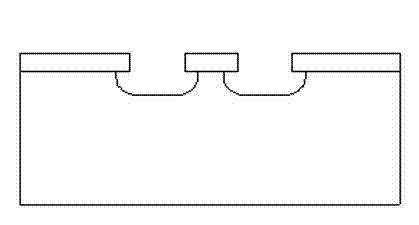

[0045] Such as figure 1 and figure 2 As shown, a micromechanical CMOS thermopile infrared temperature sensor, in order to reduce the heat conduction between the sensitive area of the sensor and the heat sink of the silicon substrate 1, it adopts a bridge structure, including the silicon substrate 1 and the silicon substrate The microbridge on 1, the photosensitive area of the sensor of the microbridge is suspended on the cavity 2 after the silicon substrate is etched, the hot end of the thermopile is located in the central area of the microbridge, and the cold end is located on the heat sink of the silicon substrate 1 , the microbridge includes a support layer made of silicon oxide film 3 and silicon nitride...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com