Sampling method and device

A sampling device and sample technology, applied in the field of gas chromatographic analysis, can solve problems such as laborious, high risk factors, and complex chromatographic flow paths, and achieve the effects of saving adjustment time, ensuring personnel safety, and simplifying chromatographic flow paths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

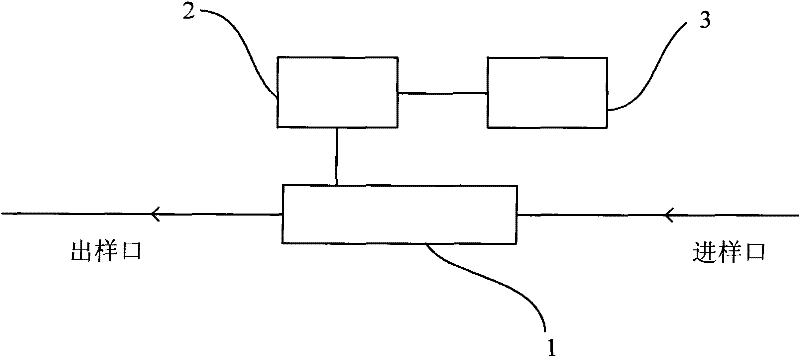

[0057] see figure 1 , a sampling device, comprising a sample inlet, a sample outlet, an enrichment tube 1, a heating element 2 and a temperature control unit 3;

[0058] The enrichment pipe 1 is a section of stainless steel pipe filled with adsorbent; the shape of the enrichment pipe 1 can be, but not limited to, cubic, spherical and barrel-shaped, and this embodiment is barrel-shaped;

[0059] Described adsorbent can be TenaxTA (2,6 diphenyl p-phenylene ether polymer resin) or TenaxGR (2,6 diphenyl p-phenyl ether polymer resin+30% graphite) or Carbotrap (graphitized carbon black) or Carbotrap C ( Graphitized carbon black) or Carboxen569 (carbon molecular sieve) or CarbosieveSIII (carbon molecular sieve); Present embodiment is TenaxTA;

[0060] The heating element 2 can be an independent heating device, or the enrichment tube itself, and the heating element 2 can be heated by energizing it; in this embodiment, the heating element 2 is an independent heating device;

[0061] ...

Embodiment 2

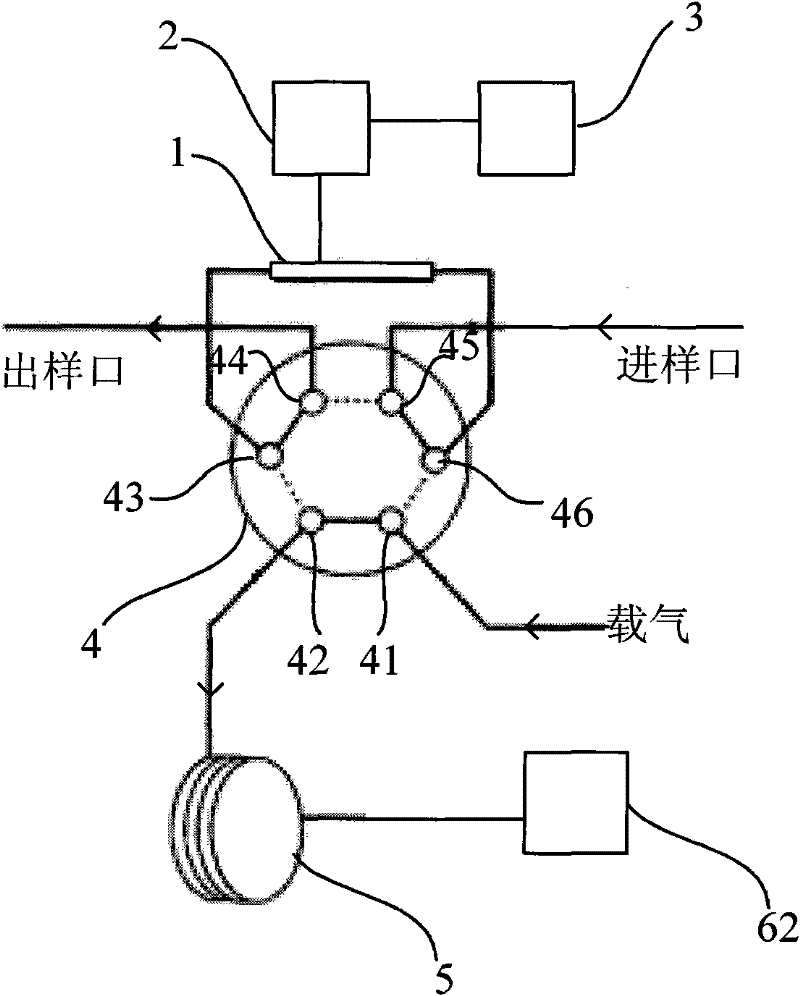

[0071] see figure 2 , a sampling device, different from the sampling device described in embodiment 1: the sampling device also includes a chromatographic analysis unit, and the chromatographic analysis unit includes a valve 4, a chromatographic column 5 and a chromatographic detector 62;

[0072] The valve 4 can be a six-way valve, an eight-way valve or a ten-way valve, etc., and it is a six-way valve in this embodiment; the valve 4 has six interfaces 41, 42, 43, 44, 45, 46;

[0073] The interface 45 is connected with the sample inlet; the interface 44 is connected with the sample outlet;

[0074] When the valve 4 is in the sampling position, the port 41 communicates with the port 42, the port 43 communicates with the port 44, and the port 45 communicates with the port 46; the carrier gas flows into the six-way valve through the port 41, directly flows out from the port 42, and reaches the chromatographic column 5; The sample to be measured flows into the enrichment tube 1 ...

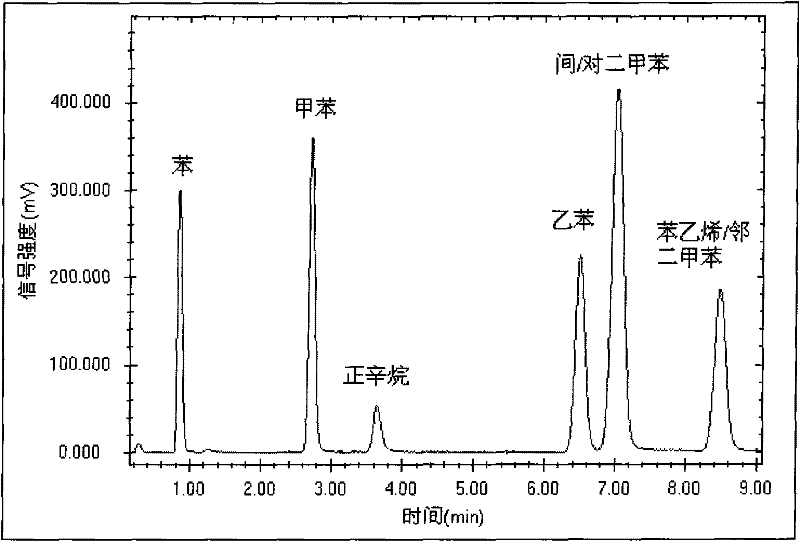

Embodiment 3

[0088] see Figure 4 , a sampling device, different from the sampling device described in embodiment 1 is:

[0089] The temperature control unit 3 is a sequential heating control unit; when setting the heating temperature of the enrichment pipe 1, the temperature duration can be set at the same time;

[0090] The sampling device also includes a detector 63; the detector 63 is connected to the sample inlet through the valve 7; the flow path formed by the valve 7 and the detector 63 is a bypass;

[0091] The detector 63 can be a thermal conductivity detector (Thermal Conductivity Detector, TCD) or a hydrogen flame ionization detector (Flame Ionization Detector, FID) or an electron capture detector (Electron Capture Detector, ECD) or a flame photometric detector ( Flame Photometric Detector, FPD) or Nitrogen-phosphorus detector (Nitrogen-phosphorus detector, NPD) or mass spectrometer detector (Mass Spectrometer Detector, MSD), this embodiment is MSD.

[0092] When the sample to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com