Antiager for Chinese yam beverage, Chinese yam beverage and method for preparing Chinese yam beverage

An anti-aging agent and yam technology are applied in the fields of anti-aging agent for yam beverage, preparation of yam beverage, and yam beverage, which can solve the problems of reduced digestion and absorption rate, poor appearance and taste of yam beverage, etc., and reduce the speed of water separation. , Broaden the market scope, improve the effect of easy aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

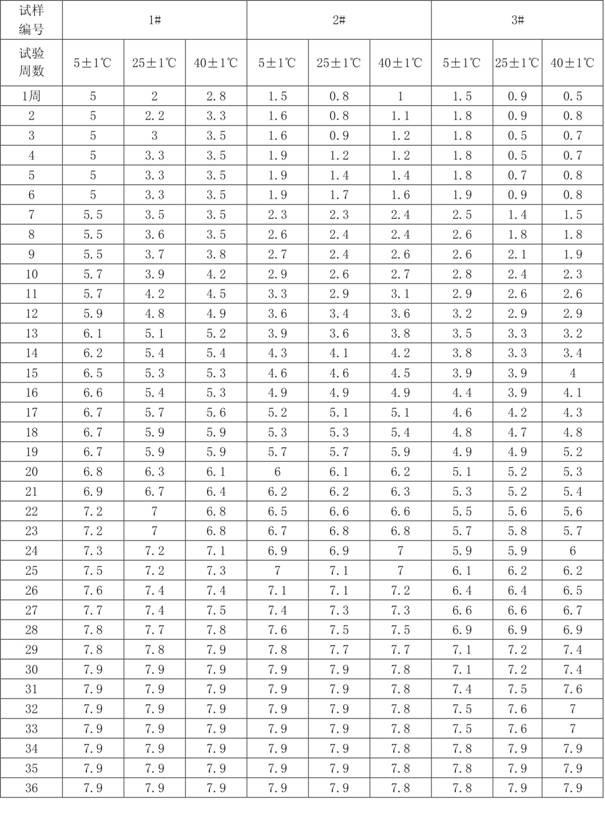

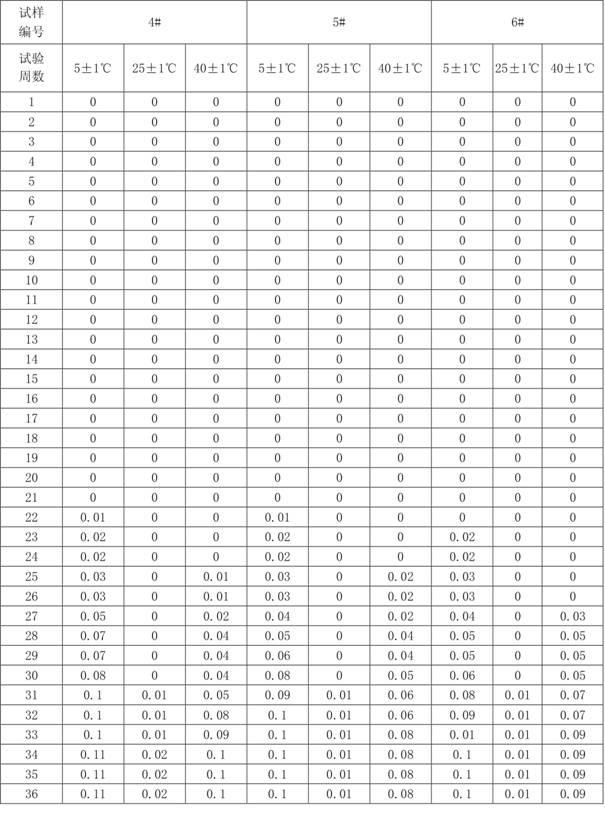

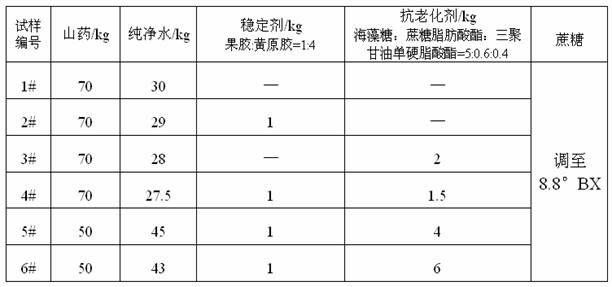

Image

Examples

Embodiment 1

[0015] The antiaging agent for yam beverage consists of 0.5 part of trehalose, 0.02 part of sucrose fatty acid ester and 0.01 part of triglycerol monostearate in parts by weight.

[0016] A yam drink is made from the following raw materials: 5kg yam, 90kg water, 0.5kg trehalose, 0.02kg sucrose fatty acid ester, 0.01kg triglycerol monostearate and an appropriate amount of sucrose; the preparation steps are:

[0017] After cleaning and sorting the yams in turn, steam them at 80°C for 30 minutes; add 10kg of water to make a pulp after cooking, pass through a 100-mesh sieve, and prepare the obtained filtrate: add trehalose, sucrose fatty acid ester, triglycerol monostearate Ester and remaining 80kg water are mixed homogeneously, and the brix degree of beverage is adjusted to 1.5 ° BX with sucrose.

[0018] After preparation, the yam drink is homogenized (55°C, 25mpa), degassed (65°C, -0.05mpa) and filled (80°C) in sequence, and then the filled yam drink is placed at 121~125°C Ste...

Embodiment 2

[0021] The antiaging agent for yam beverage consists of 1 part of trehalose, 0.1 part of sucrose fatty acid ester and 0.3 part of triglycerol monostearate in parts by weight.

[0022] A kind of yam beverage, is made from following raw material: 60kg yam, 60kg water, 1kg trehalose, 0.1kg sucrose fatty acid ester, 0.3kg tripolyglycerol monostearate, 0.1kg pectin and appropriate amount of sucrose; Its preparation steps for:

[0023] After cleaning and sorting the yams in turn, steam them at 100°C for 5 minutes; add 30kg of water to make a pulp after cooking, pass through a 60-mesh sieve, and prepare the obtained filtrate: add trehalose, sucrose fatty acid ester, triglycerol monostearate Ester, pectin and remaining 30kg water are mixed homogeneously, and the brix degree of beverage is adjusted to 5 ° of BX with sucrose.

[0024] After preparation, the yam drink is homogenized (50°C, 40mpa), degassed (85°C, -0.08mpa) and filled (80°C) in sequence, and then the filled yam drink is ...

Embodiment 3

[0026] The antiaging agent for yam beverage consists of 5 parts of trehalose, 0.8 part of sucrose fatty acid ester and 0.6 part of tripolyglycerol monostearate in parts by weight.

[0027] A kind of yam beverage, is made from following raw materials: 95kg yam, 90kg water, 5kg trehalose, 0.8kg sucrose fatty acid ester, 0.3kg tripolyglycerol monostearate, 0.2kg pectin, 0.4kg xanthan gum and An appropriate amount of sucrose; its preparation steps are:

[0028] After cleaning and sorting the yams in turn, steam them at 90°C for 10 minutes; add 40kg of water to make a pulp after cooking, pass through a 120-mesh sieve, and prepare the obtained filtrate: add trehalose, sucrose fatty acid ester, triglycerol monostearic acid Ester, pectin, xanthan gum and remaining 50kg water are mixed homogeneously, and the brix degree of drink is adjusted to 8 ° of BX with sucrose.

[0029] After preparation, the yam drink is homogenized (85°C, 25mpa), degassed (50°C, -0.03mpa) and filled (80°C) in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com