Preparation method of low-acid and high-quality ginkgo leaf extractive

A technique for ginkgo biloba leaves and extracts, which is applied in the field of preparation of low-acid and high-quality ginkgo biloba extracts, can solve problems such as adverse reactions, cumbersome extraction process, uncontrolled extraction, etc., and achieves fewer extraction process steps, high enrichment extraction rate, Reasonable effect of the process route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

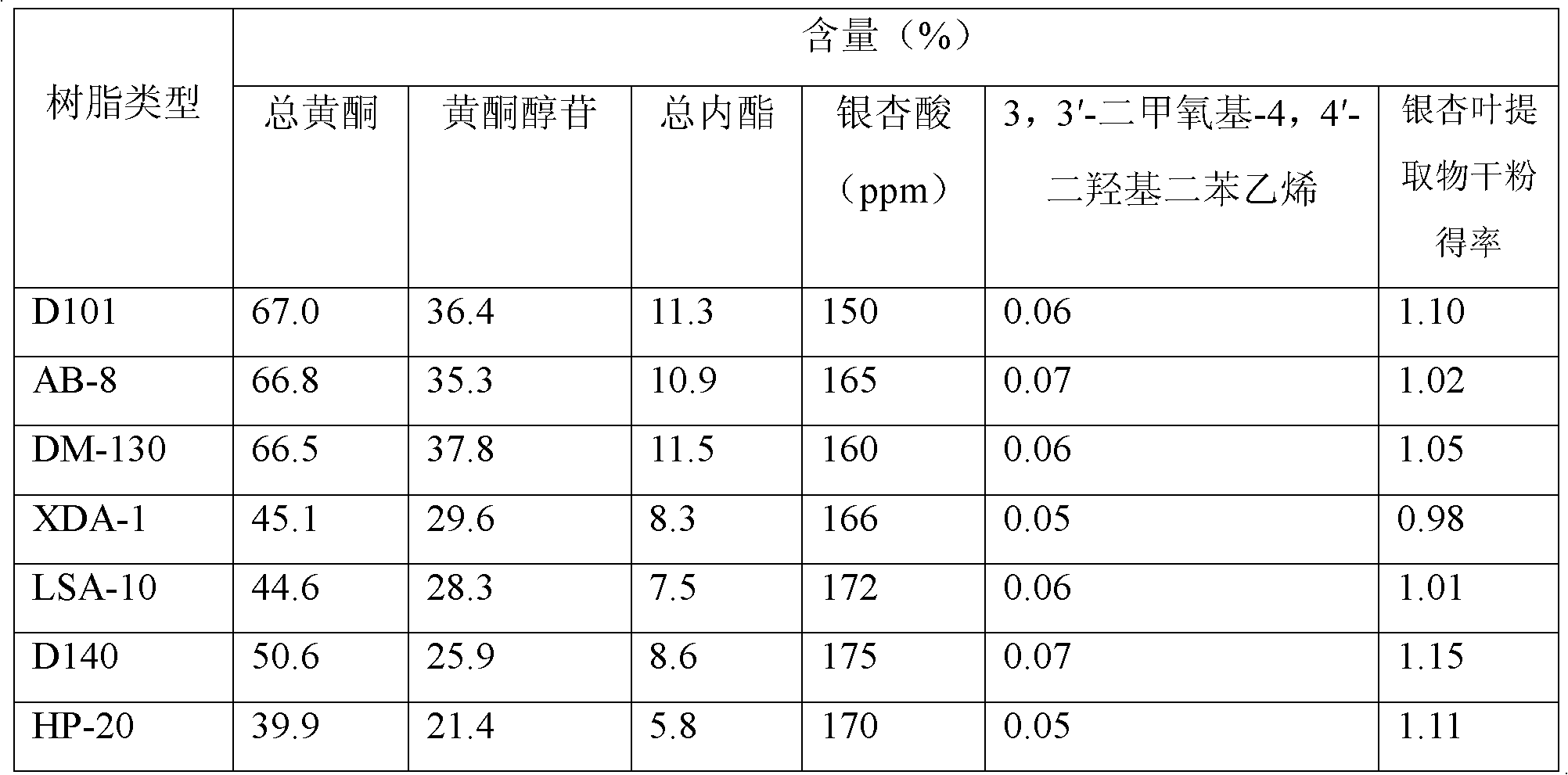

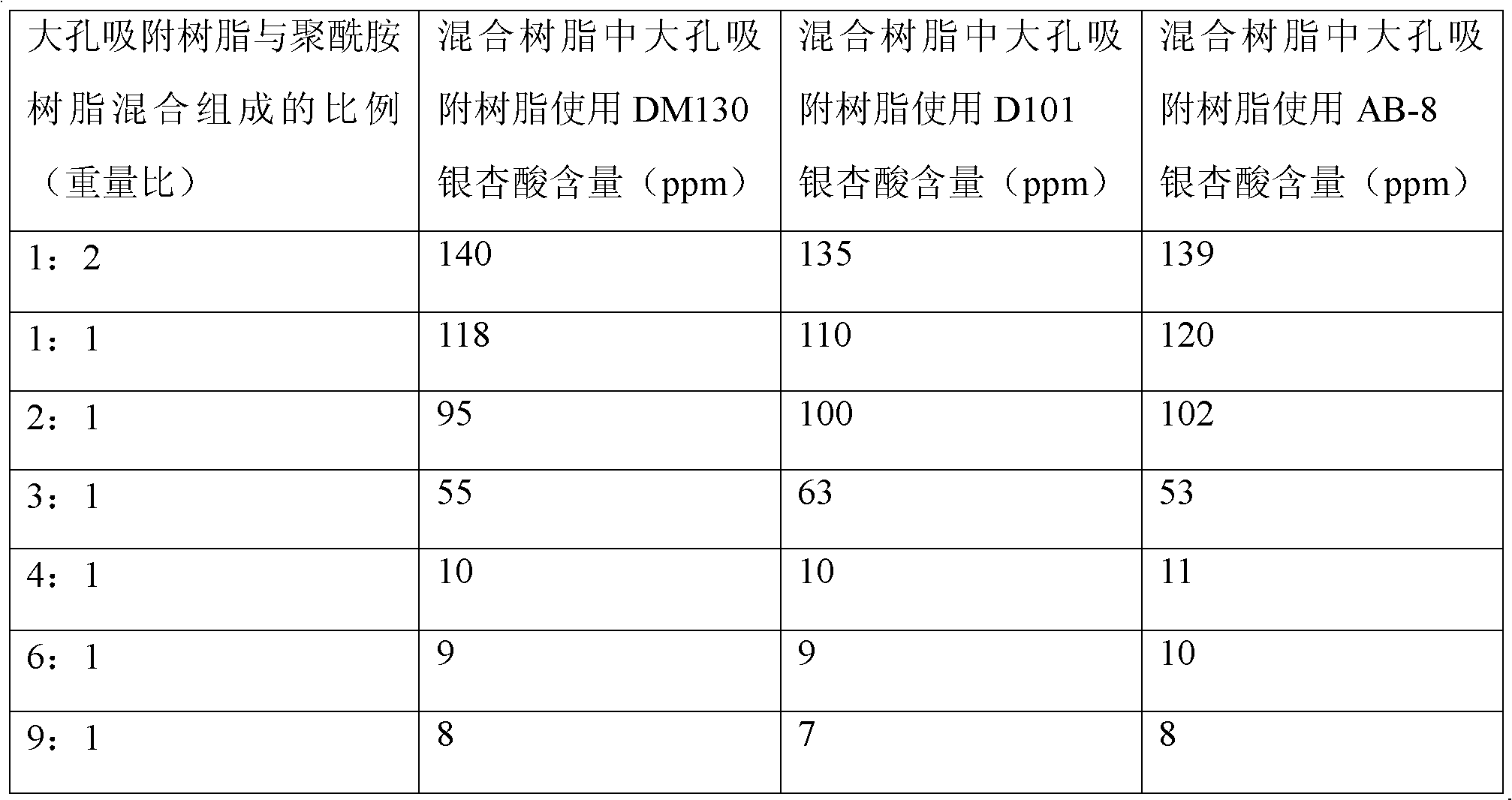

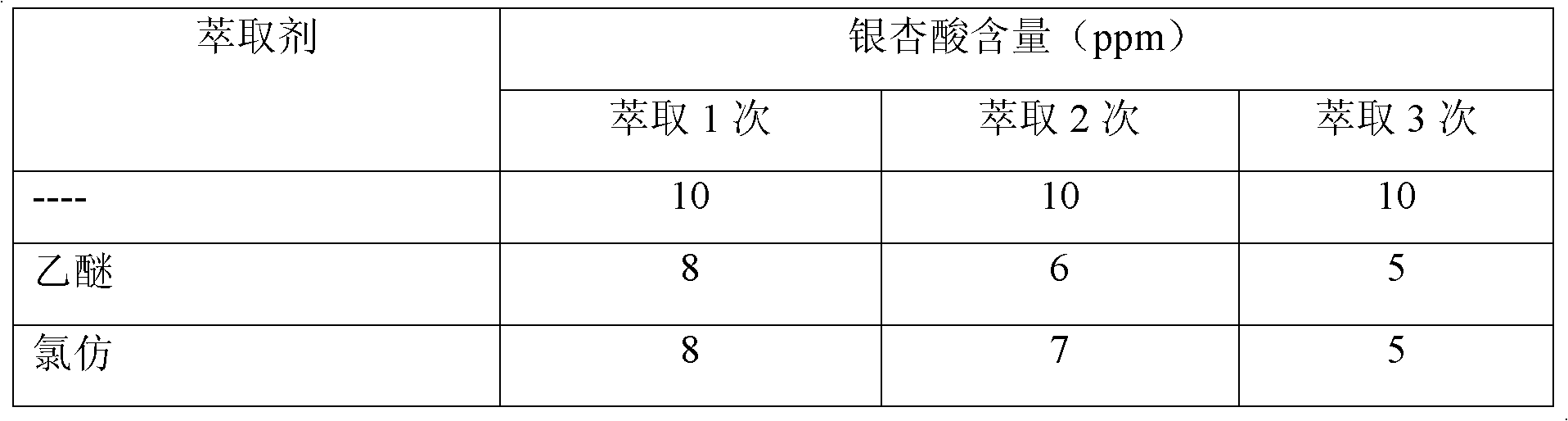

Embodiment 1

[0032]1 kg of dried ginkgo leaves, crushed to pass through a 20-mesh sieve, reflux extracted three times with 70% ethanol by mass percentage, added alcohol 14 times the weight of dried ginkgo leaves for the first time, extracted for 1 hour, added the weight of dried ginkgo leaves for the second and third times respectively 12. Extract 8 times the amount of alcohol for 1.5 hours, combine the extracts, filter, recover ethanol under reduced pressure, and concentrate to a thick paste (relative density 1.15 at 60°C). Add water in an amount 3 times the weight of the dried ginkgo leaves, stir well, put it in a cold storage at 4°C for 48 hours, and centrifuge to obtain a supernatant. With the ratio of adding 2ml supernatant per gram of resin, pass through the ion exchange column composed of mixed resin (wherein the column packing ratio of macroporous adsorption resin DM130 and polyamide resin is 9:1), and the column diameter-height ratio is 1: 6. First wash with 4 times the column vo...

Embodiment 2

[0034] Dried ginkgo leaves 5kg, crushed to pass through a 20 mesh sieve, reflux extracted three times with 80% ethanol by mass percentage, added 12 times the weight of dry ginkgo leaves for the first time, extracted for 2 hours, and 10 and 6 times the amount for the second and third times respectively , were extracted for 1.5 hours, the combined extracts were filtered, ethanol was recovered under reduced pressure, and concentrated to a thick paste (relative density at 60°C was 1.17). Add water 5 times the weight of the leaf, stir well, put it in the cold storage for 24 hours, centrifuge to obtain the supernatant. Add the ratio of 2.5ml supernatant to every gram of resin, pass through the ion exchange column (wherein the packing ratio of macroporous adsorption resin AB-8 and polyamide resin is 8: 1) that has been made up of mixed resin, pack The ratio of column diameter to height is 1:7. First wash with 4 times the column volume of distilled water, then use 6 times the column ...

Embodiment 3

[0036] 50 kg of dried ginkgo leaves were crushed through a 20-mesh sieve, and 85% ethanol was used for reflux extraction three times, the first time adding 13 times the weight of dry ginkgo leaves, extracting for 1.5 hours, the second and third times were respectively 11 and 7 times the amount, All extracts were extracted for 1 hour, the extracts were combined, filtered, ethanol was recovered under reduced pressure, and concentrated to a thick paste (relative density at 60°C was 1.20). Add water 5 times the weight of the leaves, stir well, put it in the cold storage for 48 hours, centrifuge to obtain the supernatant. Add 2ml of supernatant per gram of resin, and pass through the ion exchange column composed of mixed resin that has been treated (the column packing ratio of macroporous adsorption resin D101 and polyamide resin is 9:1), and the column diameter is high. The ratio is 1:5. Wash with 3 times the column volume of distilled water, then use 6 times the column volume of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com