Method of extracting active substances with high content of flavones from ginkgo leaves

A technology with high flavonoid content and active substances, which is applied in the field of extracting active substances with high flavonoid content, can solve the problems of low yield and many impurities in the extraction process of ginkgo biloba, achieve good adsorption-analysis effect, improve extraction rate, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

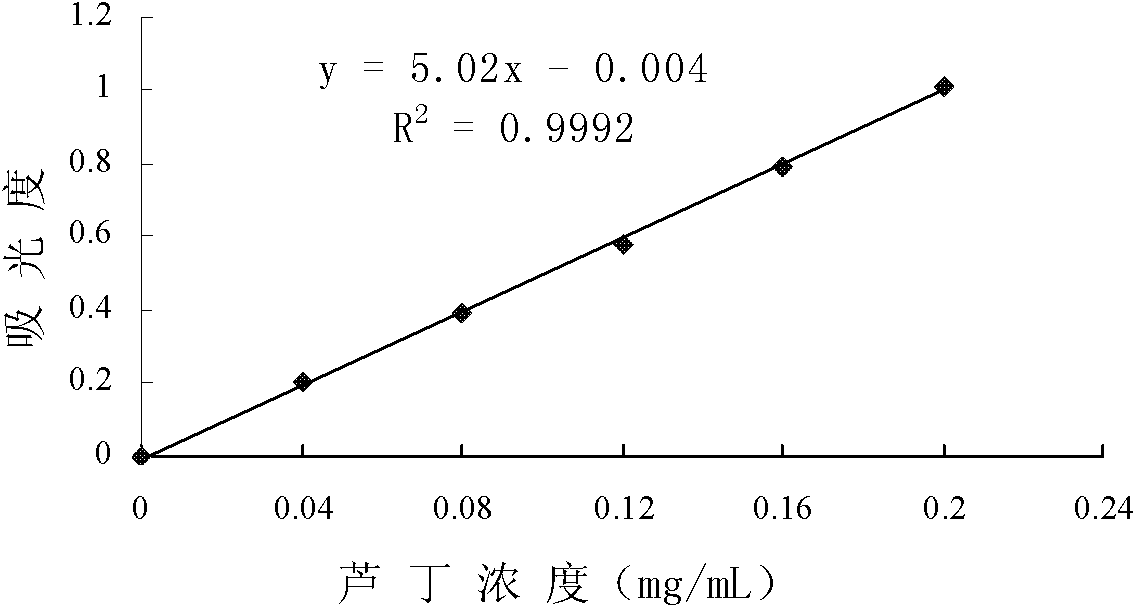

Image

Examples

Embodiment 1

[0035] (1) Ginkgo biloba powder preparation:

[0036] The dried ginkgo leaves are pulverized and passed through a 60-mesh sieve to obtain ginkgo leaf powder.

[0037] (2) Pretreatment of Ginkgo biloba:

[0038] Take 5 g of crushed ginkgo leaf powder, add 20 mL of calcium hydroxide solution with a pH of 8, and place it under a microwave power of 800 W for 3.0 min. The ginkgo leaf suspension after the microwave treatment is placed in a polyethylene bag and an equal volume of 90vt% ethanol solution is added to seal it. Place the sealed polyethylene bag under 300Mpa high pressure for 15 minutes to obtain the pretreatment solution, take it out, let it stand, and set it aside.

[0039] (3) Extraction of ginkgo biloba active substances:

[0040] Add 75vt% ethanol solution to the ginkgo biloba pretreatment solution, the liquid-to-material ratio (volume mL: mass g) is 20:1, adjust the pH to 8, heat and reflux for 60 minutes, let stand, filter, and reflux and extract the residue unde...

Embodiment 2

[0056] (1) Ginkgo biloba powder preparation:

[0057] The dried ginkgo leaves are pulverized and passed through a 60-mesh sieve to obtain ginkgo leaf powder.

[0058] (2) Pretreatment of Ginkgo biloba:

[0059] Take 5 g of crushed ginkgo leaf powder, add 20 mL of calcium hydroxide solution with a pH of 9, and place it under a microwave power of 800 W for 3.0 min. The ginkgo leaf suspension after the microwave treatment is placed in a polyethylene bag and an equal volume of 90vt% ethanol solution is added to seal it. Place the sealed polyethylene bag under 300Mpa high pressure for 15 minutes to obtain the pretreatment solution, take it out, let it stand, and set it aside.

[0060] (3) Extraction of ginkgo biloba active substances:

[0061] Add 75vt% ethanol solution to the ginkgo biloba pretreatment solution, the liquid-to-material ratio (volume mL: mass g) is 20:1, adjust the pH to 8, heat and reflux for 60 minutes, let stand, filter, and reflux and extract the residue unde...

Embodiment 3

[0077] (1) Ginkgo biloba powder preparation:

[0078] The dried ginkgo leaves are pulverized and passed through a 60-mesh sieve to obtain ginkgo leaf powder.

[0079] (2) Pretreatment of Ginkgo biloba:

[0080] Take 5 g of crushed ginkgo leaf powder, add 20 mL of calcium hydroxide solution with a pH of 10, and place it under a microwave power of 800 W for 3.0 min. The ginkgo leaf suspension after the microwave treatment is placed in a polyethylene bag and an equal volume of 90vt% ethanol solution is added to seal it. Place the sealed polyethylene bag under 300Mpa high pressure for 15 minutes to obtain the pretreatment solution, take it out, let it stand, and set it aside.

[0081] (3) Extraction of ginkgo biloba active substances:

[0082] Add 75vt% ethanol solution to the ginkgo biloba pretreatment solution, the liquid-to-material ratio (volume mL: mass g) is 20:1, adjust the pH to 8, heat and reflux for 60 minutes, let stand, filter, and reflux and extract the residue und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com