Reaction device and method for preparing nano zinc oxide

A nano-zinc oxide and reaction device technology, applied in the direction of zinc oxide/zinc hydroxide, nanotechnology, chemical industry, etc., can solve the problems of unstable quality, easy agglomeration, etc., and achieve reduced production costs, small particle size, and narrow distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

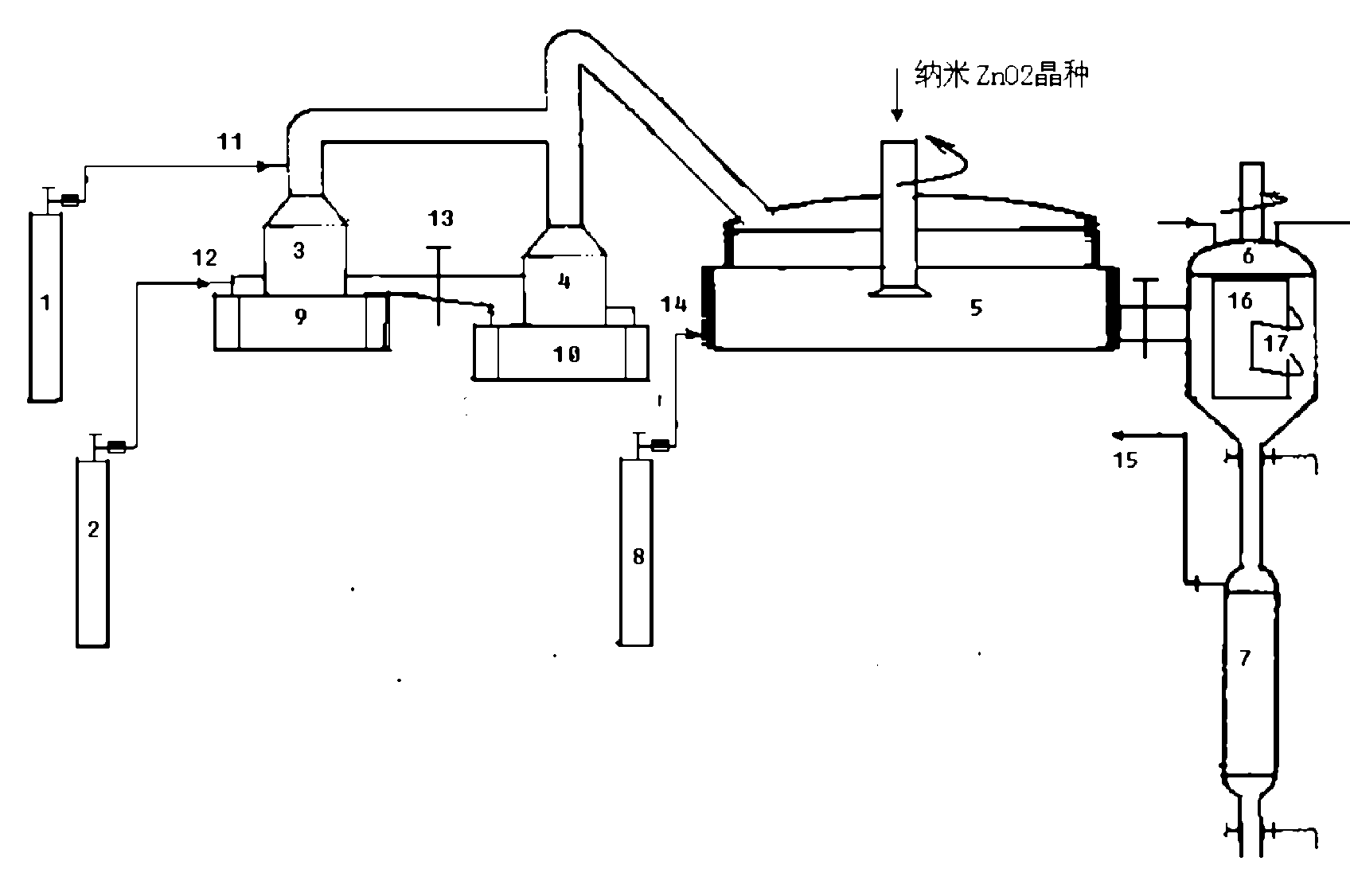

[0082] combined with figure 1 The reaction device of the present invention is described. The device includes a first arc high temperature furnace 3, a second arc high temperature furnace 4, a reactor 5, a rotary drum type extreme cooler 6 and a collector 7 connected in sequence by pipelines. The first arc high temperature The furnace 3, the second electric arc high temperature furnace 4, the reactor 5, the rotary drum type extreme cooler 6 and the collector 7 are airtightly connected to the pipeline respectively; the bottom of the inner cavity of the first electric arc high temperature furnace 3 is provided with a first crucible 9 The bottom of the inner chamber of the first electric arc high temperature furnace 3 is provided with air intake passages 11 and 12 with control valves communicating with the outside world, and the inner chamber bottom of the second electric arc high temperature furnace 4 is provided with a second crucible 10 , a channel 13 with a valve is provided b...

Embodiment 2

[0085] Fill liquid nitrogen into the drum of the drum-type extreme cooler, and start the extreme cooler with a rotating speed of 250r / min. A 23kg weight zinc ingot is placed in the first crucible, and the valve between the first crucible and the second crucible is opened. The device is evacuated to make the vacuum degree 150Pa, and then filled with nitrogen and argon in sequence, and the first crucible is heated to 600°C under the protection of argon, and the molten zinc ingot flows into the second crucible after melting, and is heated to 700°C to obtain Zinc vapor, zinc vapor is filled into the reactor with argon as the carrier gas, and high-purity oxygen is filled from the reactor gas inlet, and the reactor is heated to a temperature of 900°C. The volume flow rate of argon gas is 27 liters / hour, the volume flow rate of high-purity oxygen gas is 100 liters / hour, the volume flow ratio of argon gas and high-purity oxygen gas is 27:100, and nano ZnO is put into the reactor 2Rod...

Embodiment 3

[0087] Fill liquid nitrogen into the drum of the rotary-drum-type ultra-cooler, and start the ultra-cooler at a speed of 175 r / min. A 23kg weight zinc ingot is placed in the first crucible, and the valve between the first crucible and the second crucible is opened. The device is evacuated to a vacuum degree of 200 Pa, and then filled with nitrogen and argon in sequence, and the first crucible is heated to 600°C under the protection of argon, and the melt flows into the second crucible after the zinc ingot is melted, and is heated to 800°C to obtain Zinc vapor, zinc vapor is filled into the reactor with argon as the carrier gas, and high-purity oxygen is filled from the reactor gas inlet, and the reactor is heated to a temperature of 900°C. The volume flow rate of argon gas is 30 liters / hour, the volume flow rate of high-purity oxygen gas is 100 liters / hour, the volume flow ratio of argon gas and high-purity oxygen gas is 30:100, and nano ZnO is put into the reactor 2 Rod-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com