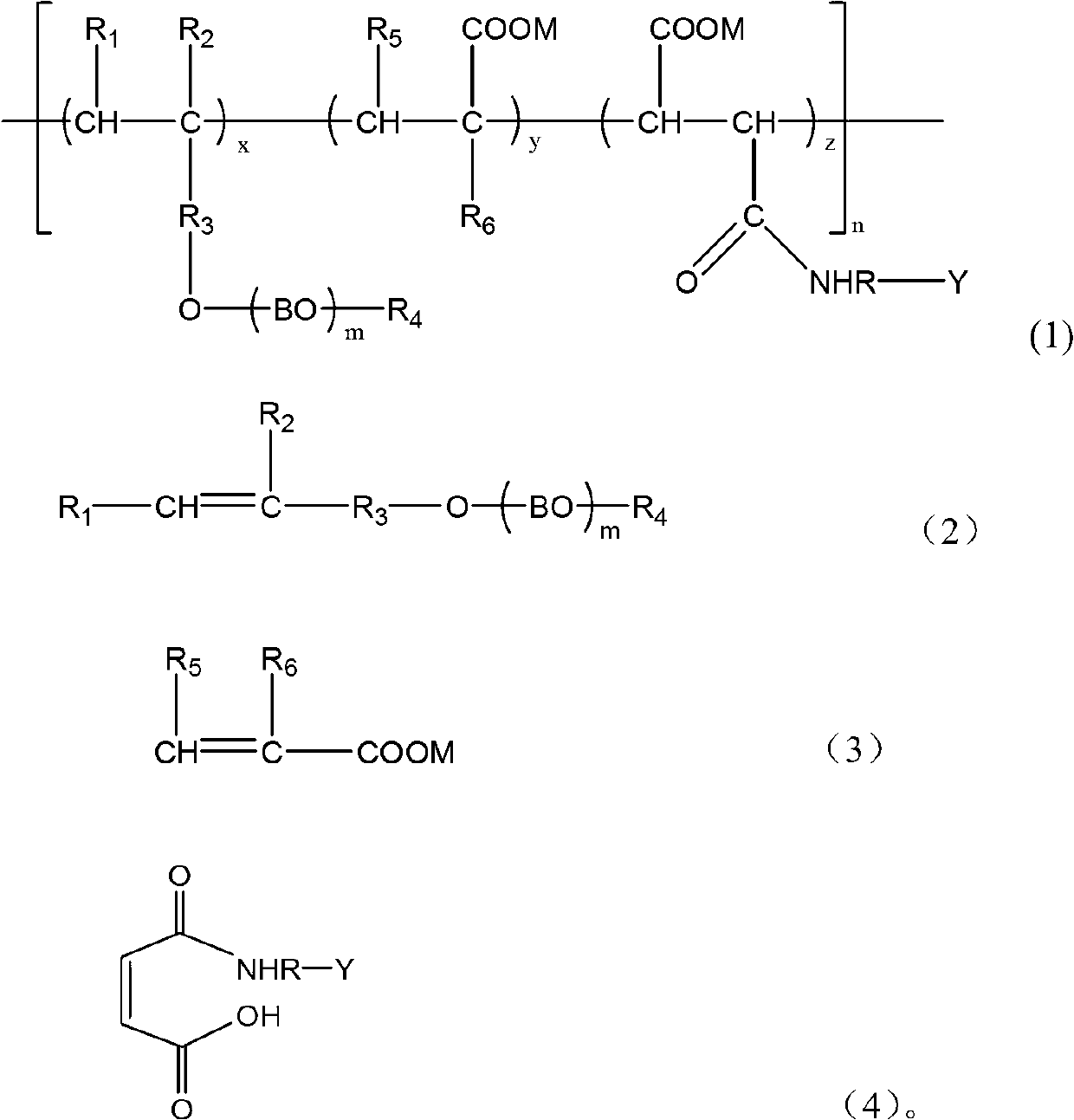

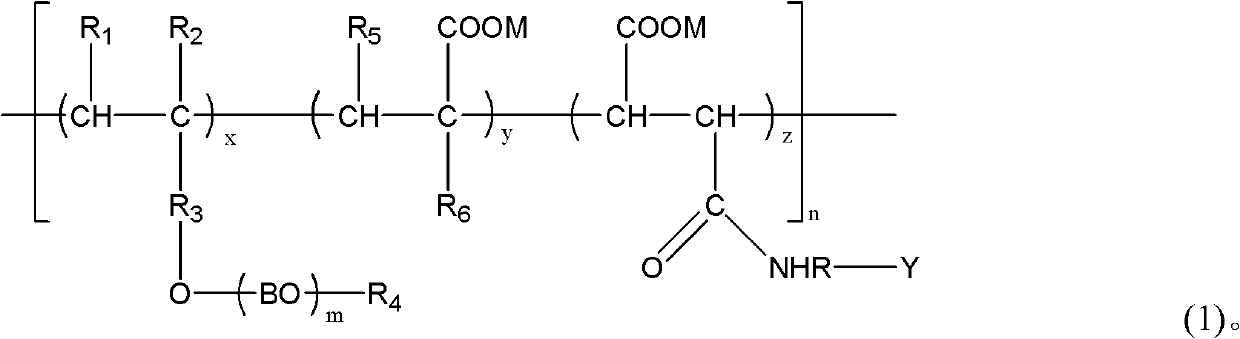

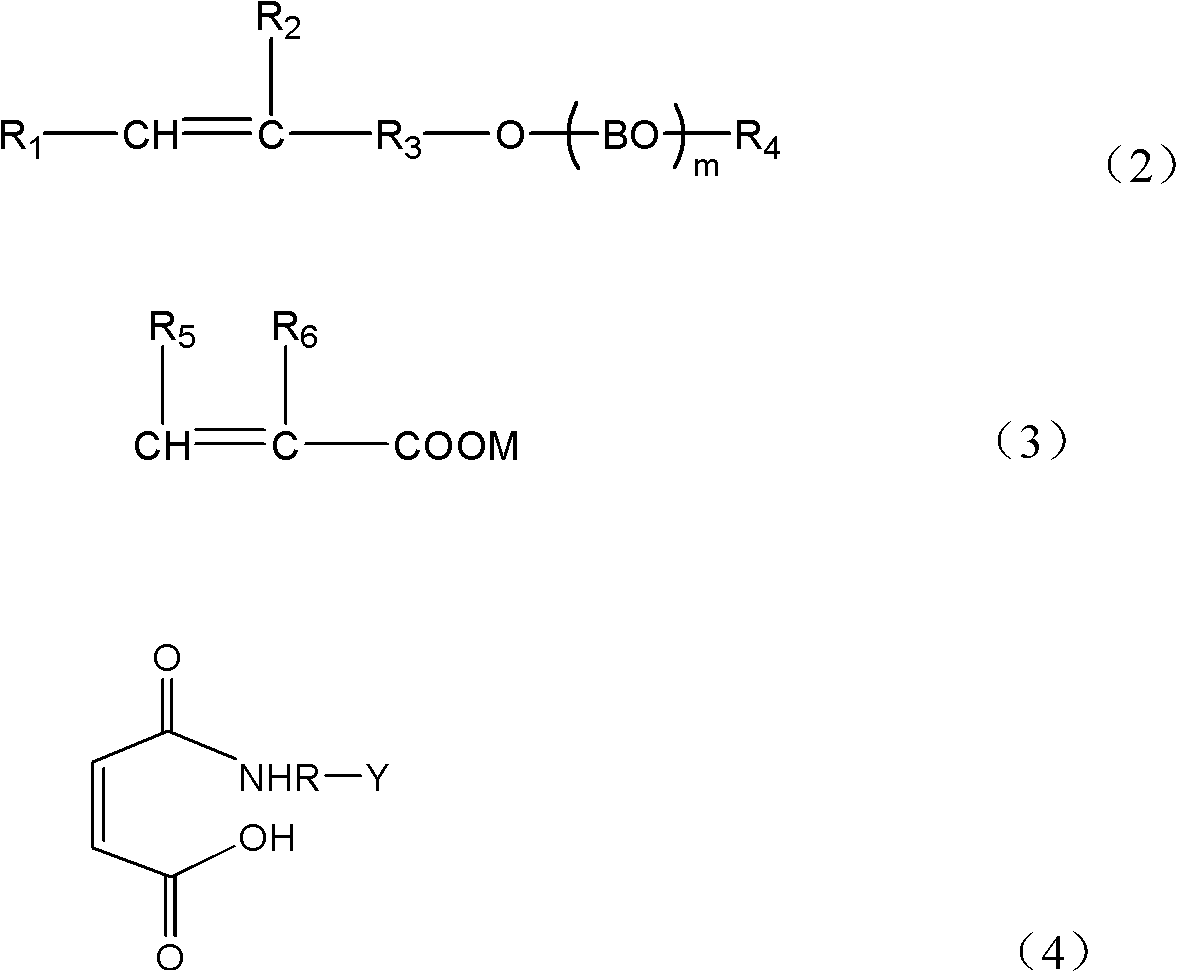

Polycarboxylic acid water reducing agent and preparation method thereof

A technology of polycarboxylic acid series and water reducing agent, used in the field of concrete polycarboxylic acid series water reducing agent, can solve the problems of unsatisfactory product performance, difficult process control, low water reduction rate, etc., and achieves safety and environmental friendliness. , moderate activity, improve the effect of adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Put 240 grams of AL (weight average molecular weight 2400) and 147 grams of water into the reaction kettle, turn on the agitator, slowly heat up to 50°C, add 12.60 grams of hydrogen peroxide solution with a mass concentration of 30%, and wait until the temperature rises to 50°C to stabilize Afterwards, add dropwise the 2# aqueous solution 48.2g that contains 2.0680 gram Vc and 3.7366 gram MPA; After treating that 2# solution is added dropwise 2min, begin to drip the 1# aqueous solution 39.2 grams that contain 19.6 gram MA and 0.92 gram c1, the time for adding is 3 hours. After adding 1# and 2# aqueous solution, keep it at 50°C for 1 hour. Then lower the temperature to below 30°C, and then use 30% sodium hydroxide solution to neutralize to a pH value of 7 to obtain a polycarboxylate water reducer product of the present invention, whose structural formula is shown in formula (5): Weight average molecular weight: 15000~30000.

[0052]

[0053] Wherein, x:y=1:1.5-2.5, ...

Embodiment 2

[0055] Add 240 grams of MAL (weight average molecular weight 2400) and 147 grams of water into the reaction kettle, turn on the stirrer, slowly heat up to 60°C, add 10.95 grams of hydrogen peroxide solution with a mass concentration of 30%, and wait until the temperature rises to 60°C to stabilize Afterwards, 48.2 g of 2# aqueous solution containing 1.7972 g of Vc and 3.2473 g of MPA was added dropwise; the dropping time was 3.5 hours. After 2# was added dropwise for 2 minutes, 39.2 grams of 1# aqueous solution containing 19.6 grams of AA and 4.15 grams of C2 was added dropwise, and the dropping time was 3 hours. After adding 1# and 2# aqueous solution, keep it at 60°C for 1 hour. Then lower the temperature to below 30°C, and then neutralize with 30% sodium hydroxide solution until the pH value is 7, and then obtain a polycarboxylate water reducer product of the present invention, its structure is shown in formula (6): Weight average molecular weight: 20000~35000.

[0056] ...

Embodiment 3

[0059] Add 240 grams of MAL (weight average molecular weight 2400) and 147 grams of water into the reaction kettle, turn on the stirrer, slowly heat up to 60°C, add 10.95 grams of hydrogen peroxide solution with a mass concentration of 30%, and wait until the temperature rises to 60°C to stabilize Afterwards, 48.2 g of 2# aqueous solution containing 1.7972 g of Vc and 3.2473 g of MPA was added dropwise; the dropping time was 3.5 hours. After 2# was added dropwise for 2 minutes, 39.2 grams of 1# aqueous solution containing 19.6 grams of AA and 2.82 grams of C3 was added dropwise, and the dropping time was 3 hours. After the 1# and 2# aqueous solutions are added, keep at 60°C for 1 hour, then cool down to below 30°C, and then neutralize with 30% sodium hydroxide solution to a pH value of 7 to obtain a polycarboxylic acid reducing agent of the present invention. The liquid product has a structure as shown in formula (7): the corresponding weight-average molecular weight: 20,000-3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com