Holmium-ytterbium-doped lithium potassium niobate monocrystal and preparation method thereof

A technology of potassium lithium niobate single crystal, applied in the field of potassium lithium niobate single crystal and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

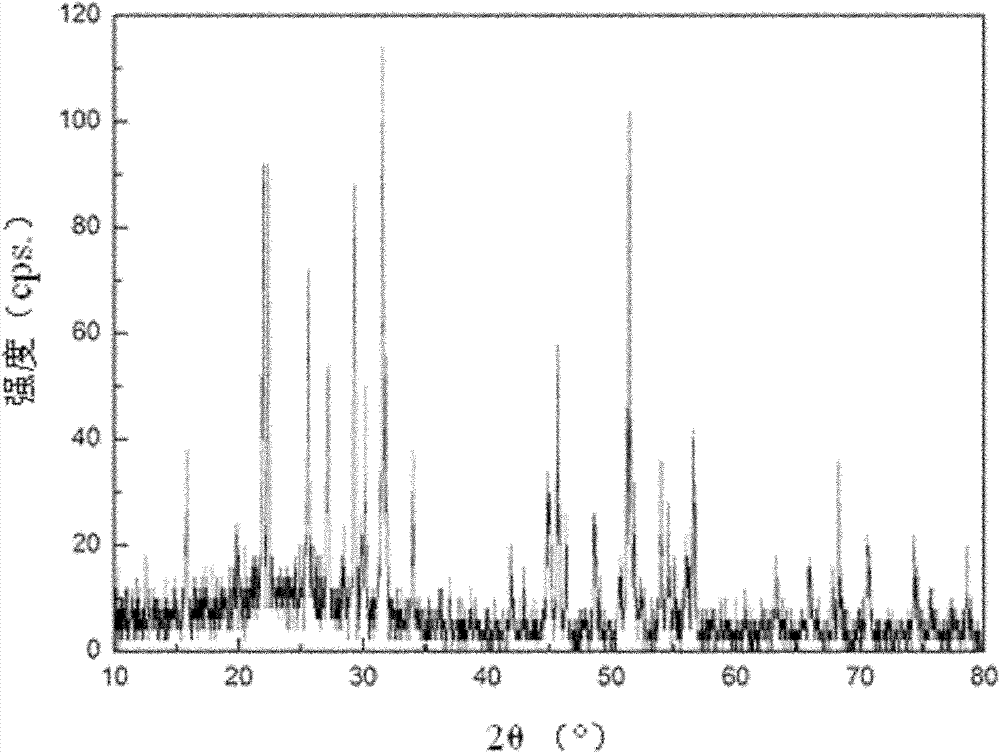

[0010] Embodiment 1: The holmium-ytterbium double doped potassium niobate lithium single crystal of this embodiment is made of ytterbium oxide, holmium oxide, niobium oxide, lithium carbonate and potassium carbonate, wherein the molar ratio of ytterbium oxide to holmium oxide is 1 : 0.5 to 8, the molar ratio of ytterbium oxide to niobium oxide is 1: 1263 to 1428, the molar ratio of ytterbium oxide to lithium carbonate is 1: 571 to 637, and the molar ratio of ytterbium oxide to potassium carbonate is 1: 857 to 957.

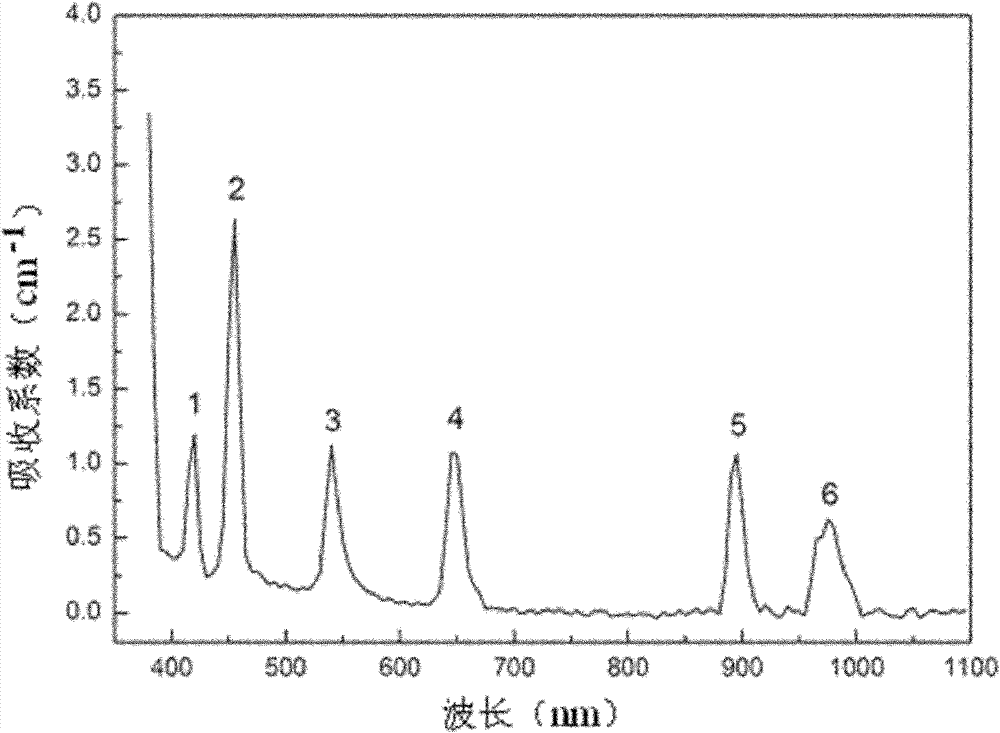

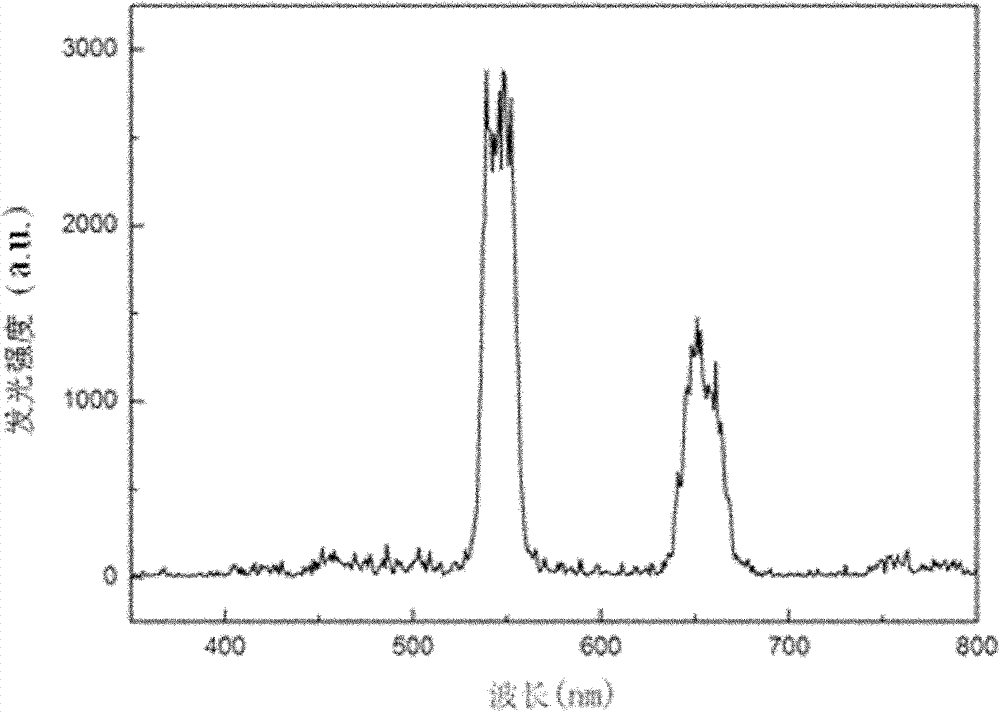

[0011] This embodiment successfully produces a holmium-ytterbium double-doped potassium lithium niobate single crystal that is transparent, uniform in quality, free of growth streaks, and superior in performance by adopting a gradual cooling method. The ultraviolet absorption edge of the crystal is around 380nm, which makes the typical absorption band of holmium in the ultraviolet region less than 380nm impossible to observe, while in its ultraviolet-visible-near-in...

specific Embodiment approach 2

[0012] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the molar ratio of ytterbium oxide to holmium oxide is 1:1 to 7, the molar ratio of ytterbium oxide to niobium oxide is 1:1270 to 1400, and the molar ratio of ytterbium oxide to niobium oxide is 1:1270 to 1400. The molar ratio of lithium carbonate is 1:580-625, and the molar ratio of ytterbium oxide to potassium carbonate is 1:865-950. Others are the same as the first embodiment.

specific Embodiment approach 3

[0013] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the molar ratio of ytterbium oxide to holmium oxide is 1:5, the molar ratio of ytterbium oxide to niobium oxide is 1:914, and the molar ratio of ytterbium oxide to lithium carbonate is 1:914. The ratio was 1:611, and the molar ratio of ytterbium oxide to potassium carbonate was 1:1331. Others are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com