Seamless can, printing plate, cylindrical printer for seamless can, printing method for seamless can, and method for producing seamless can

A technology of curved surface printing and printing methods, which is applied to printing machines, rotary printing machines, printing plates, etc. It can solve the problems of reducing the strength of the coating film, damaging the aesthetics of seamless cans, and easily producing scars, so as to prevent the aesthetics from being affected. The effect of reducing damage, suppressing the generation of wrinkles, and reducing the height difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

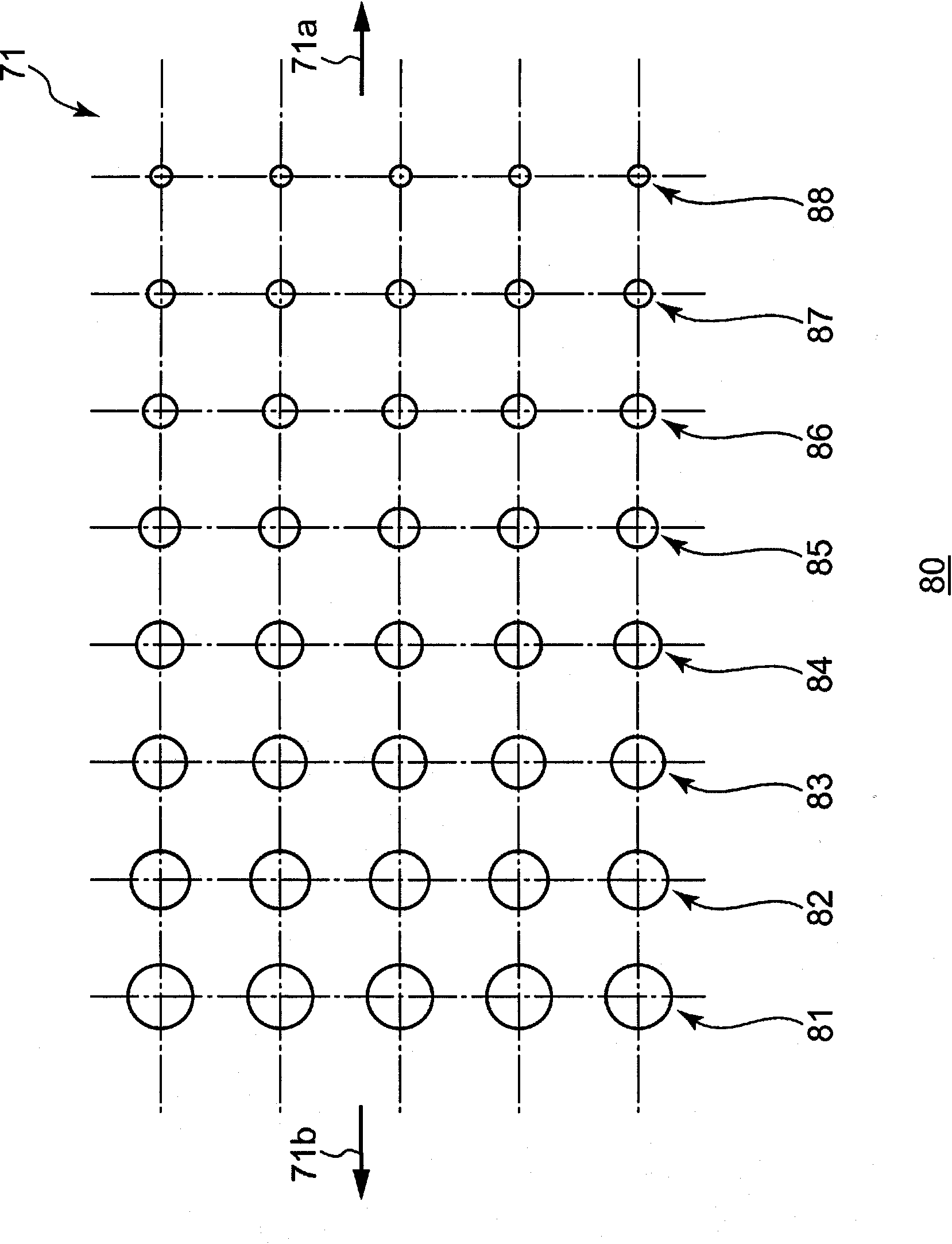

[0152] Using a resin relief plate as a printing plate, and using the above-mentioned resin relief ink, a halftone dot gradation is formed at the printing start part, and a halftone dot gradation is formed at the printing end part, thereby producing a seamless can. As a result of the evaluation, the evaluation of coating film strength was ○ (H), the evaluation of shrinkage wrinkles was ○ (occurrence rate 0%), and the overall evaluation was ○.

Embodiment 2

[0154] A seamless can was produced in the same manner as in Example 1 except that solid printing was performed on the printing start portion of the printing plate. The evaluation results were Δ(F) for coating film strength, Δ for neck-in wrinkle (occurrence rate: 10%), and Δ for overall evaluation.

Embodiment 3

[0156] A seamless can was fabricated in the same manner as in Example 1, except that the printing end portion of the printing plate was solid-printed. The evaluation results were Δ(F) for coating film strength, Δ for neck-in wrinkle (occurrence rate: 14%), and Δ for overall evaluation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com