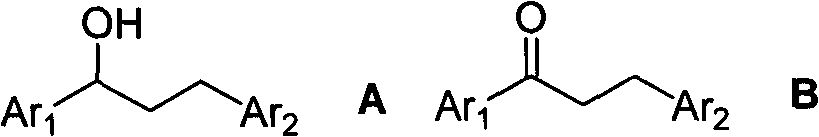

Method for synthesizing 1,3-diphenyl-1-propanol compound

A synthesis method and diphenyl technology are applied in the field of cross-coupling reaction between secondary alcohol and primary alcohol, which can solve the problems of unsuitable obtainment of ligands, the need for special preparation, and the increase of post-processing costs, so as to reduce the difficulty of purification and post-processing. Reduced environmental impact and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Under nitrogen, ferrocene 0.1mmol, 18.6mg, Cs 2 CO 3 1.0mmol, 32.6mg, 1-phenyl-ethanol 10.0mmol, 1.22g and benzyl alcohol 15.0mmol, 1.62g were sequentially added to 6.7mL of anhydrous m-xylene; stirred at 125°C for 8h. Cool to NH 4 Neutralize the reaction solution with a saturated Cl solution, extract it with ethyl acetate, and concentrate the extract in vacuo until there is no ethyl acetate odor; purify it by 100-200 mesh forward silica gel column chromatography, n-hexane: ethyl acetate = 40:1 After elution, the product 1,3-diphenyl-1-propanol 1.55g, 7.3mmol, yield: 73% can be obtained.

Embodiment 2

[0039] Under nitrogen, ferrocene formaldehyde 0.5mmol, 107.0mg, NaOH 2.0mmol, 80.0mg, 1-phenyl-ethanol 10.0mmol, 1.22g and 4-methoxybenzyl alcohol 10.0mmol, 1.38g were added in sequence for 10.0 mL of anhydrous p-xylene; at 130 ° C, stirred for 24h. Cool to NH 4 The reaction solution was neutralized with a saturated Cl solution, extracted with ethyl acetate, and the extract was concentrated in vacuo until there was no ethyl acetate smell. Purified by 100-200 mesh forward silica gel column chromatography, eluting with n-hexane:ethyl acetate=30:1, the product 1-phenyl-3-(4'-methoxyphenyl)-1-propane can be obtained Alcohol 2.33g, 9.6mmol, yield: 96%.

Embodiment 3

[0041] Under nitrogen, ferrocenemethanol 1.0mmol, 216.1mg, KOH 1.5mmol, 84.2mg, 1-(4'-methylphenyl)-ethanol 10.0mmol, 1.36g and 4-chlorobenzyl alcohol 20.0mmol, 2.85 g, successively added to 5.0 mL of anhydrous o-xylene. At 135°C, stir for 12h; cool, add NH 4 Neutralize the reaction solution with a saturated Cl solution, extract it with ethyl acetate, and concentrate the extract in vacuo until there is no ethyl acetate odor; purify it by 100-200 mesh forward silica gel column chromatography, n-hexane: ethyl acetate = 38:1 After elution, the product 1-(4'-methylphenyl)-3-(4'-chlorophenyl)-1-propanol 2.11g, 8.1mmol, yield: 81% can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com