Preparation method for light anti-reflection protective film of space solar cell

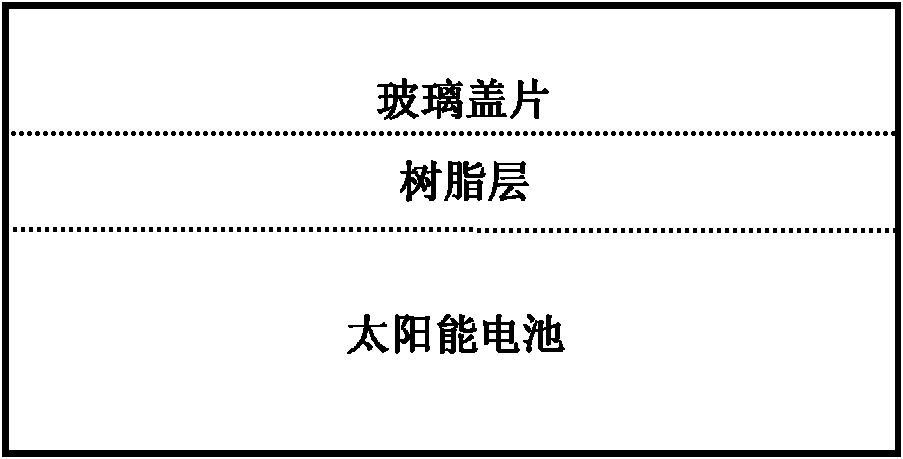

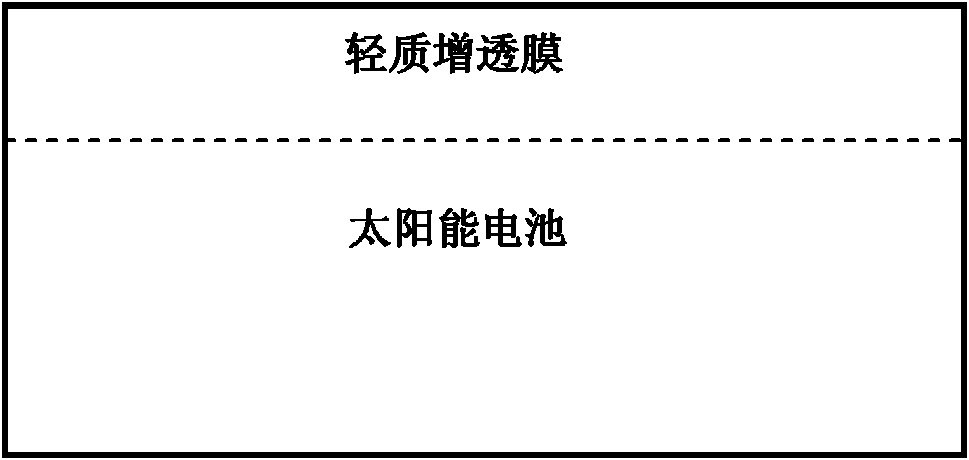

A technology of solar cells and protective films, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems affecting the launch and work cost, efficiency, service life and reliability of space vehicles, reduce the photoelectric conversion efficiency of solar cells, and glass surface Smoothness, light transmittance, etc., to achieve effective physical protection, improve transmittance, and reduce energy consumption in space operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Using ethanol, deionized water and ethyl orthosilicate at a volume ratio of 40:5:9 as raw materials, hydrochloric acid as a catalyst, and PH=2.5 at 65 to carry out hydrolysis polycondensation reaction. Fully stir for 1 hour, and let it stand for 4 hours to prepare for coating;

[0025] The battery substrate was pretreated with hydrofluoric acid and sodium hydroxide respectively, rinsed several times with deionized water, then ultrasonically cleaned in absolute ethanol for 10 minutes, and dried for later use;

[0026] Coat the substrate with a coating machine at room temperature. The coating machine is set at the first section of rotating speed 500 rpm / s, and the time is 8s; the second section of rotating speed is 5000 rpm / s, and the time is 30s; after coating, put it into the In the Furnace, the heating rate is controlled at 8-10°C / min, and the temperature is kept at 110°C for 10 minutes; the temperature is raised to 280°C and held for 10 minutes; the temperature is con...

Embodiment 2

[0028] The hydrolysis polycondensation reaction is carried out at 75° C. with ethanol, deionized water and tetraethyl orthosilicate at a volume ratio of 45:6:12 as raw materials, hydrochloric acid as a catalyst, and pH=3.0. Fully stir for 3 hours, and let it stand for about 8 hours to prepare for coating;

[0029] The battery substrate was pretreated with hydrofluoric acid and sodium hydroxide respectively, rinsed several times with deionized water, then ultrasonically cleaned in absolute ethanol for 20 minutes, and dried for later use;

[0030] Coat the substrate with a coating machine at room temperature. The coating machine is set at the first section of rotating speed 500 rpm / s, and the time is 8s; the second section of rotating speed is 5000 rpm / s, and the time is 30s; after coating, put it into the In the Furnace, the heating rate is controlled at 8-10°C / min, and the temperature is kept at 110°C for 10 minutes; the temperature is raised to 280°C and held for 10 minutes; ...

Embodiment 3

[0032] The hydrolysis polycondensation reaction is carried out at 70° C. with ethanol, deionized water and ethyl orthosilicate at a volume ratio of 42:5:11 as raw materials, hydrochloric acid as a catalyst, and pH=3.0. Fully stir for 2 hours, and let it stand for about 5 hours to prepare for coating;

[0033] The battery substrate was pretreated with hydrofluoric acid and sodium hydroxide respectively, rinsed several times with deionized water, then ultrasonically cleaned in absolute ethanol for 15 minutes, and dried for later use;

[0034] Coat the substrate with a coating machine at room temperature. The coating machine is set at the first section of rotating speed 500 rpm / s, and the time is 8s; the second section of rotating speed is 5000 rpm / s, and the time is 30s; after coating, put it into the In the Furnace, the heating rate is controlled at 8-10°C / min, and the temperature is kept at 115°C for 10 minutes; the temperature is raised to 290°C and held for 10 minutes; the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com