Hollow-fiber membrane and process for production of hollow-fiber membrane

A manufacturing method and silk membrane technology, applied in the field of hollow fiber membranes, can solve the problems of reducing the diameter of double-ring nozzles and unrealistic industry, and achieve the effects of increasing the filling membrane area, low exchange frequency, and reducing energy load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088]15 parts by weight of polysulfone (hereinafter PSf, manufactured by BASF Corporation: ULTRASONE S6010), 7 parts by weight of polyvinylpyrrolidone (hereinafter PVP, manufactured by ISP Corporation K-90: molecular weight 1.2 million), 75 parts by weight of dimethylacetamide ( The following DMAc) and 3 parts by weight of water were dissolved and stirred to prepare a membrane-forming stock solution. The viscosity of the membrane-forming stock solution at 40° C. was 3.4 Pa·s. This film-forming stock solution was discharged from a double-ring nozzle with a peripheral slit width of 0.15 mm kept at 40° C., passed through a predetermined dry length, and was wound up at 36 m / min after coagulation and water washing. In this case, the discharge amount of the membrane-forming stock solution was adjusted so that the thickness of the hollow fiber membrane was 0.07 mm and the outer diameter was 0.36 mm. In addition, the discharge linear velocity in the double ring nozzle obtained by ...

Embodiment 2

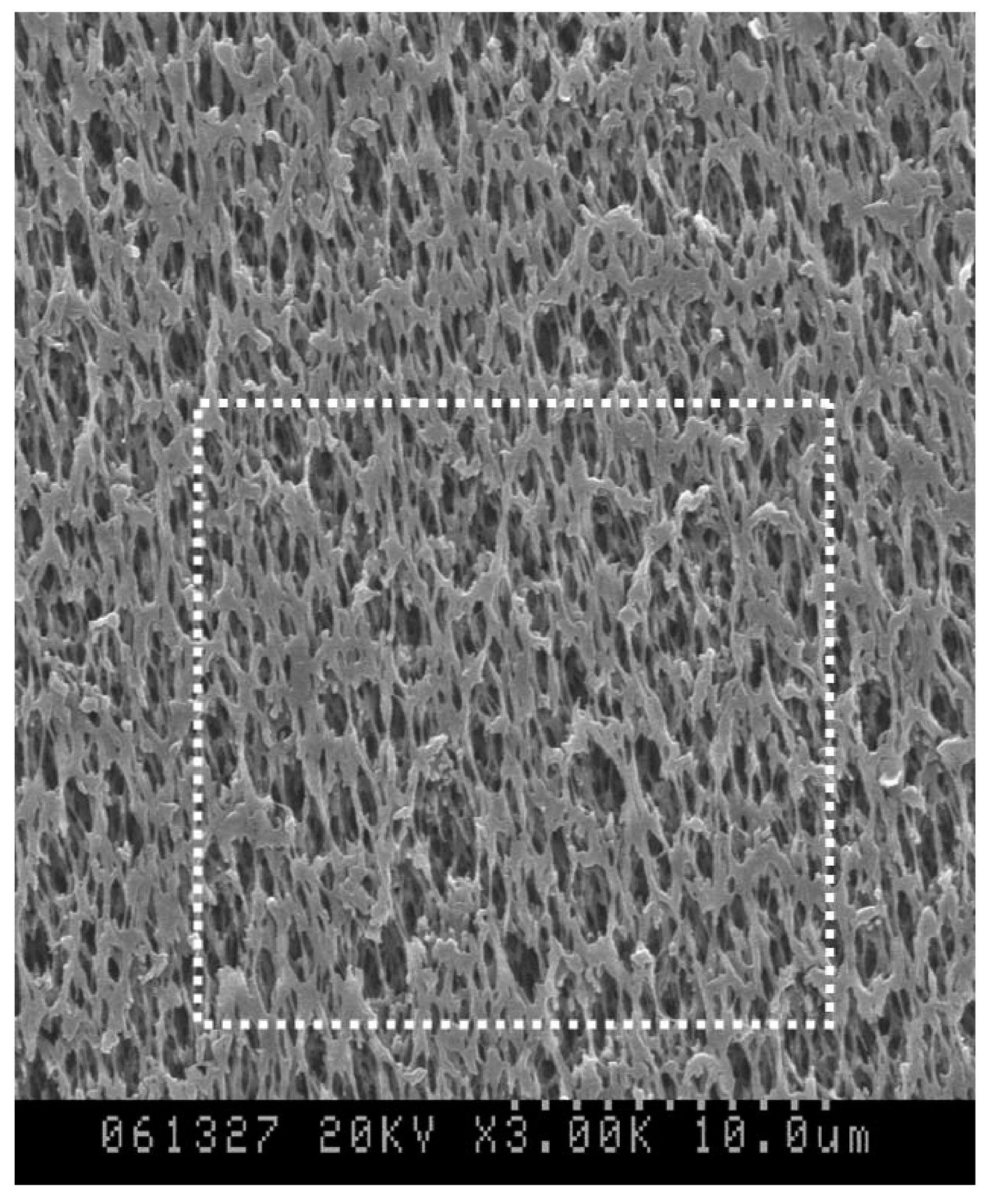

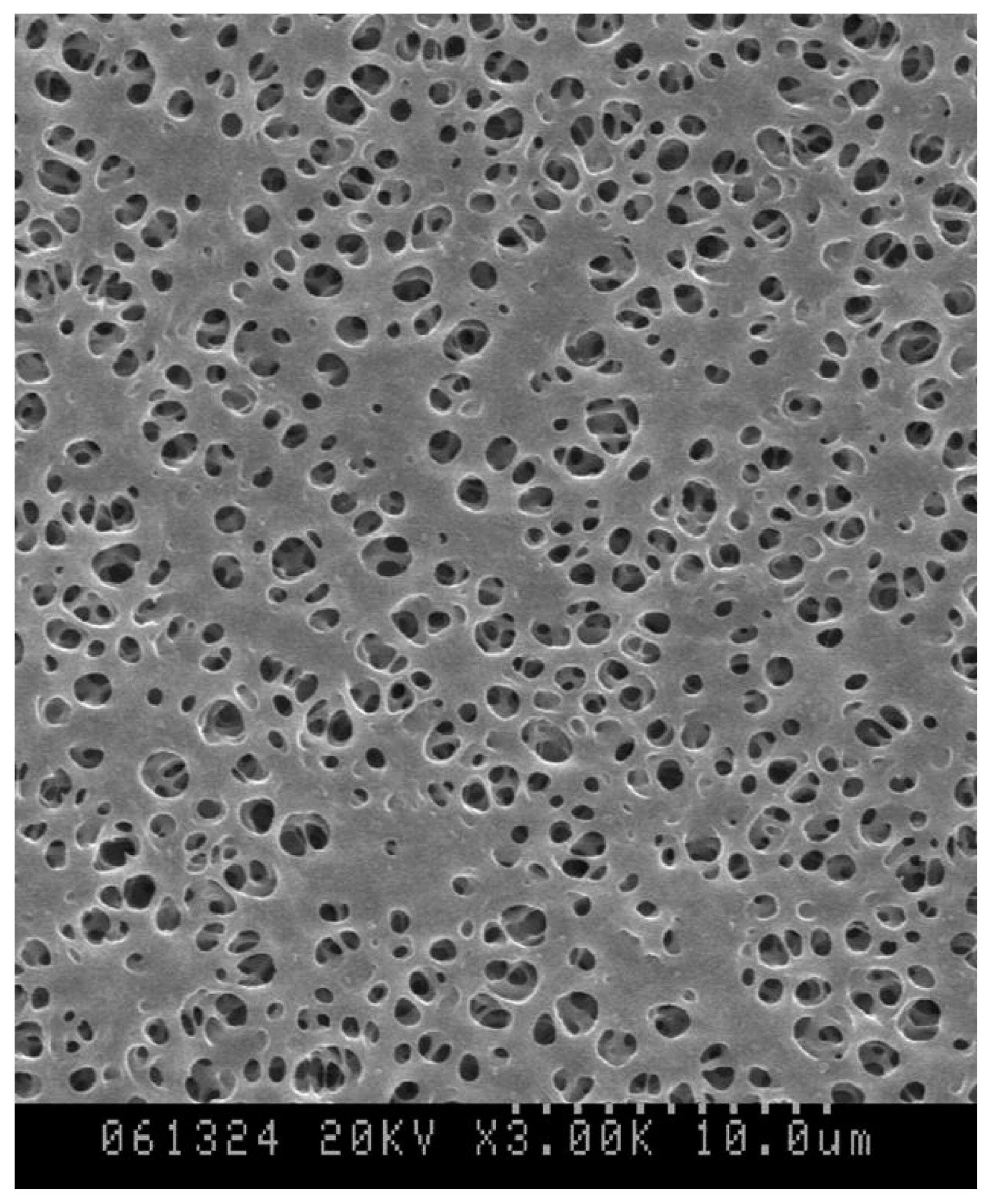

[0093] A hollow fiber membrane was produced by the same method as in Example 1, and the discharge amount of the membrane-forming stock solution was adjusted so that the thickness of the hollow fiber membrane was 0.065 mm and the outer diameter was 0.35 mm. The spinning draft ratio at this time was 7.0. The obtained hollow fiber membrane has an asymmetric structure, and a dense structure is formed on the outer surface. 2-a and 2-b are SEM photographs of the outer surface and inner surface of the film obtained in Example 2. When the porosity was measured based on this, the porosity of the outer surface was 13.7%, the porosity of the inner surface was 17.1%, and no large voids were formed on both surfaces of the film.

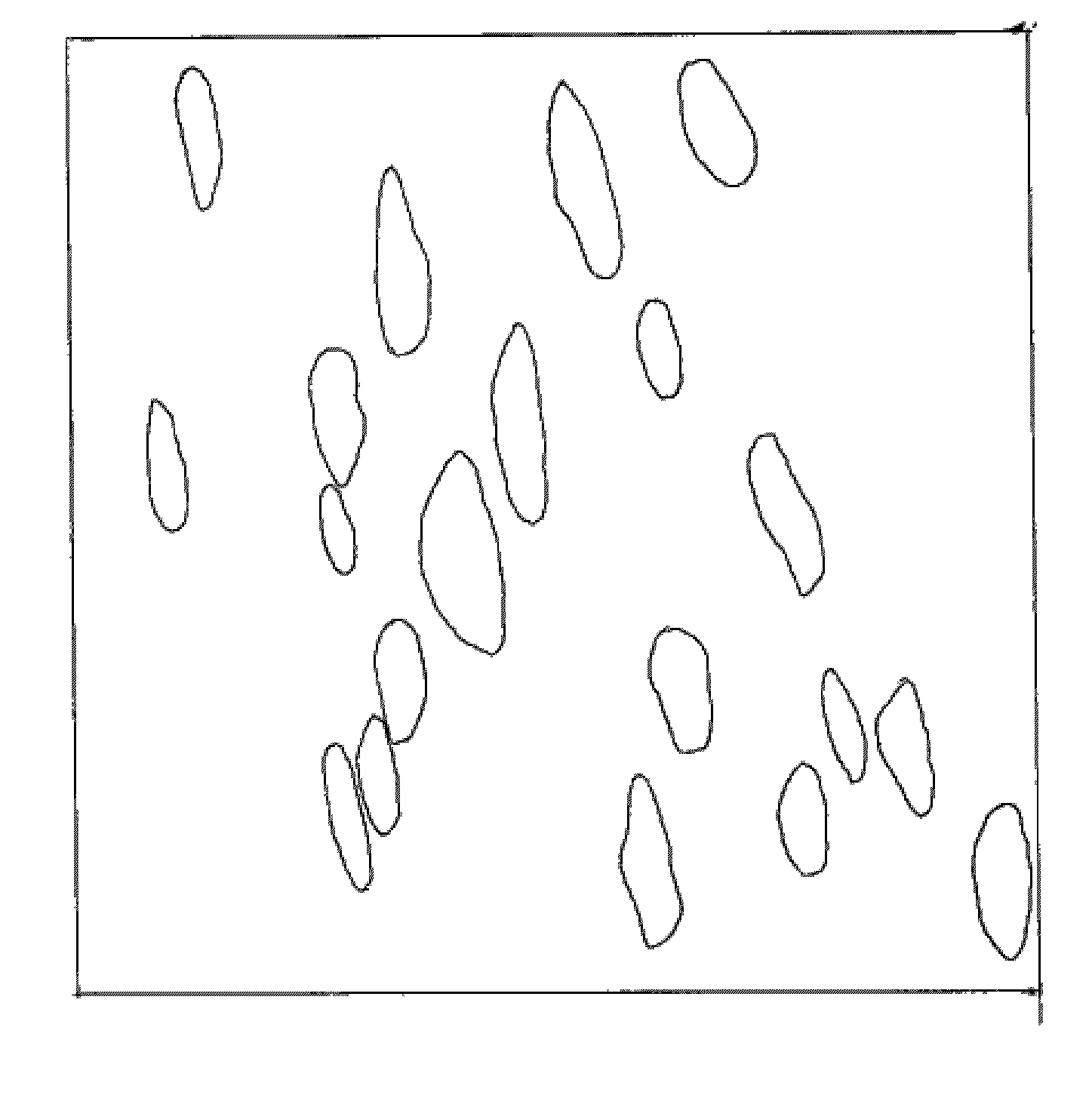

[0094] Based on the thick white dotted line in Figure 2-a, the pores formed on the outer surface of the hollow fiber membrane were extracted in the same manner as in Example 1 (Figure 2-c), and when the aspect ratio was measured, the aspect ratio was 3.7 and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Membrane area | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com