Process for treating high-concentration oil refining wastewater

A refinery wastewater and treatment process technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of large floor area, insufficient financial resources, and many failure points, etc. Achieve the effects of saving equipment investment and operating costs, stable operation, and clarified water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

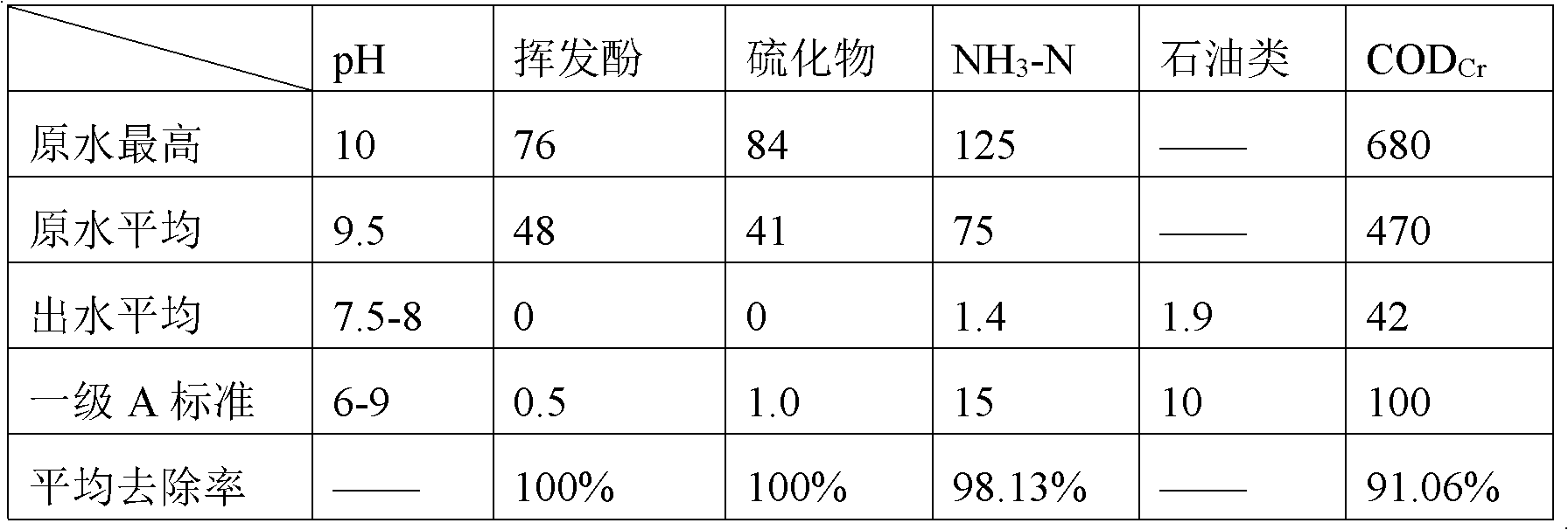

[0026] Example 1: A medium-sized local oil refinery discharges 1,440 tons of high-concentration oil refining wastewater per day, and the water quality indicators of the inflow and outflow water are:

[0027] Table 1 Unit: mg / L

[0028]

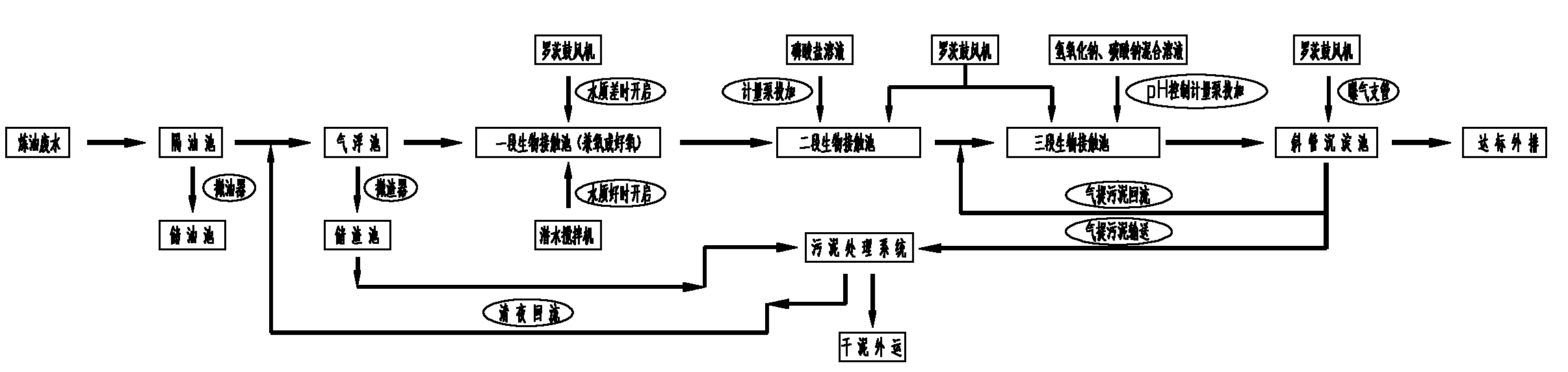

[0029] The treatment process is as follows:

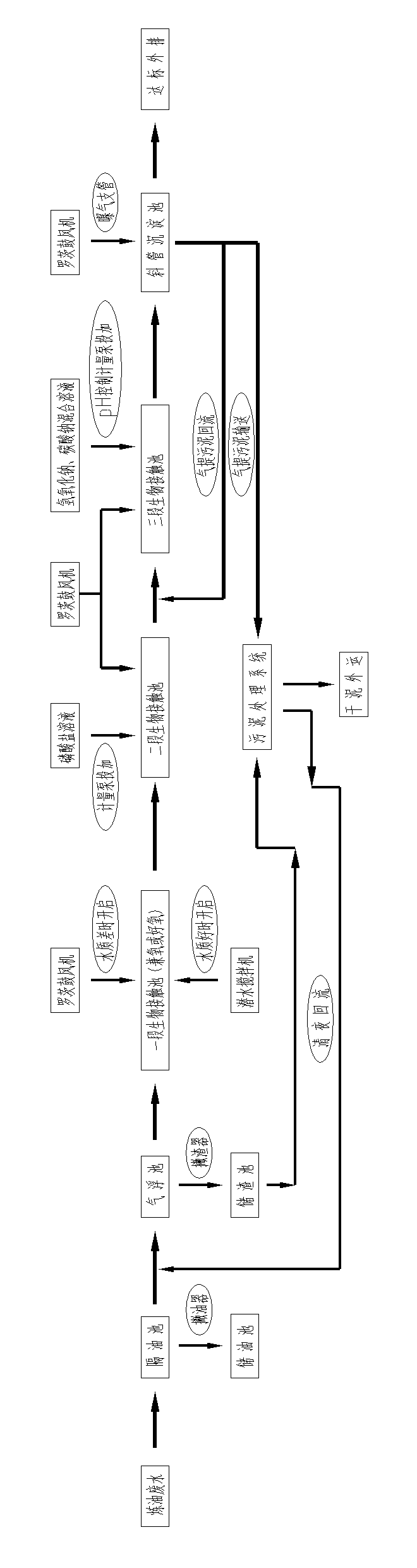

[0030] ■Refinery wastewater pretreatment unit

[0031] The refinery wastewater is subjected to physical and chemical pretreatment such as oil separation and air flotation to remove all slick oil, most emulsified oil and other solid suspended matter contained in the wastewater, and reduce the pollutant load of the subsequent biochemical treatment system as much as possible.

[0032] ■The first biochemical treatment

[0033] The first biological contact pool is a facultative and aerobic dual-purpose biological contact pool. Therefore, when the wastewater quality is good (main pollutant concentration: COD Cr ≤350mg / L, NH 3 -N≤45mg / L), the first stage of biochemical treatment is set as a facult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com