Carbon source-sulfur composite material for autotrophic denitrification and denitrification, preparation method and application

An autotrophic denitrification and composite material technology, which is applied in the field of preparation of carbon source-sulfur composite materials for autotrophic denitrification and denitrification, and can solve the problems of low strength, intolerant of long-term immersion in sewage, intolerant of gas-water backwashing, etc. , to achieve the effect of improving strength and toughness, excellent resistance and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

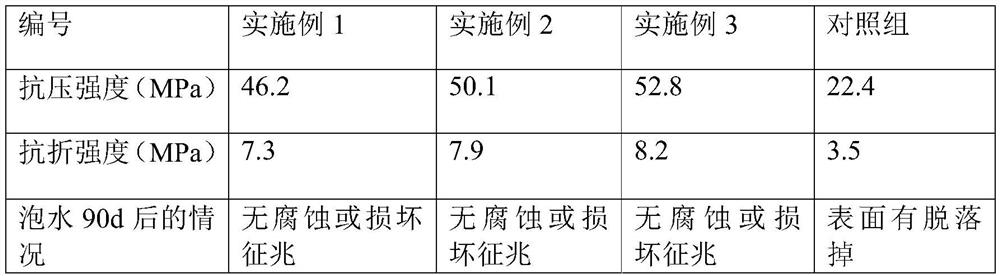

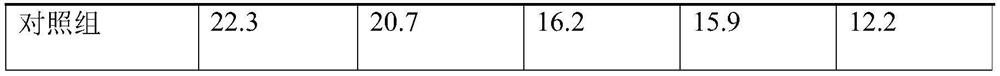

Examples

Embodiment 1

[0034] A carbon source-sulfur composite material for autotrophic denitrification and denitrification is prepared from the following raw materials in parts by weight: 60 parts of sulfur, 10 parts of coarse aggregate, 20 parts of filler, 3 parts of sulfur modifier and toughening The content of sulfur in the sulfur is not less than 95%, the coarse aggregate is limestone of 40-80 mesh, and the filler is calcium carbonate powder of 325 mesh; the sulfur modifier is composed of 1.5 parts by weight of dicyclopentadiene It is mixed with 1.5 parts of cyclopentadiene; the toughening agent is paraffin.

[0035] The above-mentioned preparation method of carbon source-sulfur composite material for autotrophic denitrification and denitrification comprises the following steps:

[0036] (1) At 1.5m 3 Put 600 kg of sulfur particles into the heated stirring tank, set the temperature in the tank to 130 °C, turn on the heating device, and keep stirring during the heating process to prevent local ...

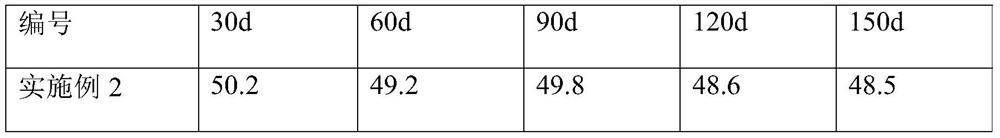

Embodiment 2

[0045] A carbon source-sulfur composite material for autotrophic denitrification and denitrification is prepared from the following raw materials in parts by weight: 50 parts of sulfur, 20 parts of coarse aggregate, 30 parts of filler, 2 parts of sulfur modifier and toughening The content of sulfur in the sulfur is not less than 95%, the coarse aggregate is 100-120 mesh limestone, and the filler is 800 mesh heavy calcium carbonate powder; the sulfur modifier is dicyclopentadiene; the toughening agent is Polysulfide rubber.

[0046] The above-mentioned preparation method of carbon source-sulfur composite material for autotrophic denitrification and denitrification comprises the following steps:

[0047] (1) At 1.5m 3 Put 500 kilograms of sulfur particles into the heated stirring tank, set the temperature in the tank to 135 °C, turn on the heating device, and continuously stir during the heating process to prevent local overheating and scorching of the sulfur;

[0048] (2) aft...

Embodiment 3

[0055] A carbon source-sulfur composite material for autotrophic denitrification and denitrification is prepared from the following raw materials in parts by weight: 60 parts of sulfur, 10 parts of coarse aggregate, 30 parts of filler, 2.5 parts of sulfur modifier and toughening The content of sulfur in sulfur is not less than 95%, the coarse aggregate is 80-120 mesh dolomite sand, and the filler is 400 mesh heavy calcium carbonate powder; the sulfur modifier is dicyclopentadiene; toughening The agent is polyethylene resin.

[0056] The above-mentioned preparation method of carbon source-sulfur composite material for autotrophic denitrification and denitrification is characterized in that it comprises the following steps performed in sequence:

[0057] (1) At 2m 3 Put 600 kg of sulfur particles into the heated stirring tank, set the temperature in the tank to 130 °C, turn on the heating device, and keep stirring during the heating process to prevent local overheating and scor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com