Method for treating waste water from production of metronidazole

A technology for producing wastewater and treatment methods, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. The effect of reducing pollutant concentration, eliminating biological toxicity and improving biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

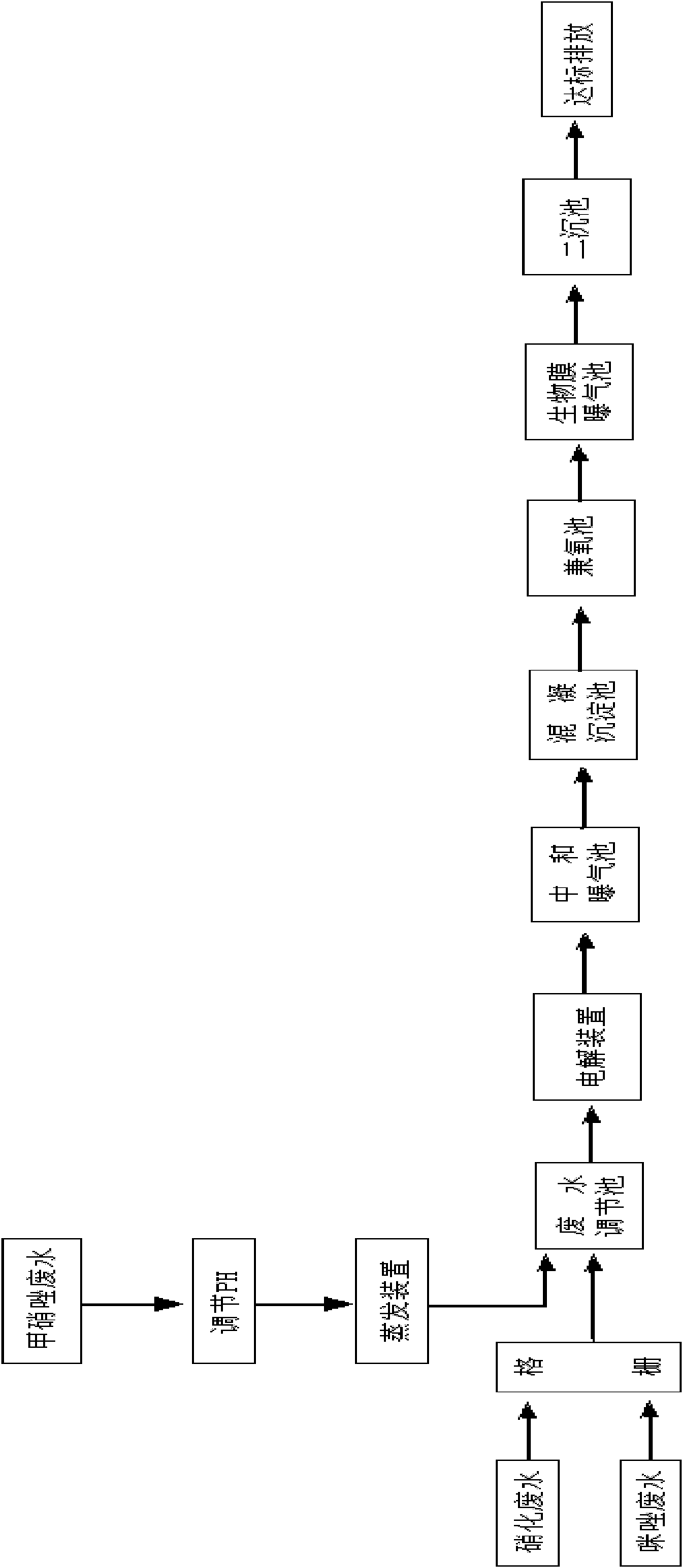

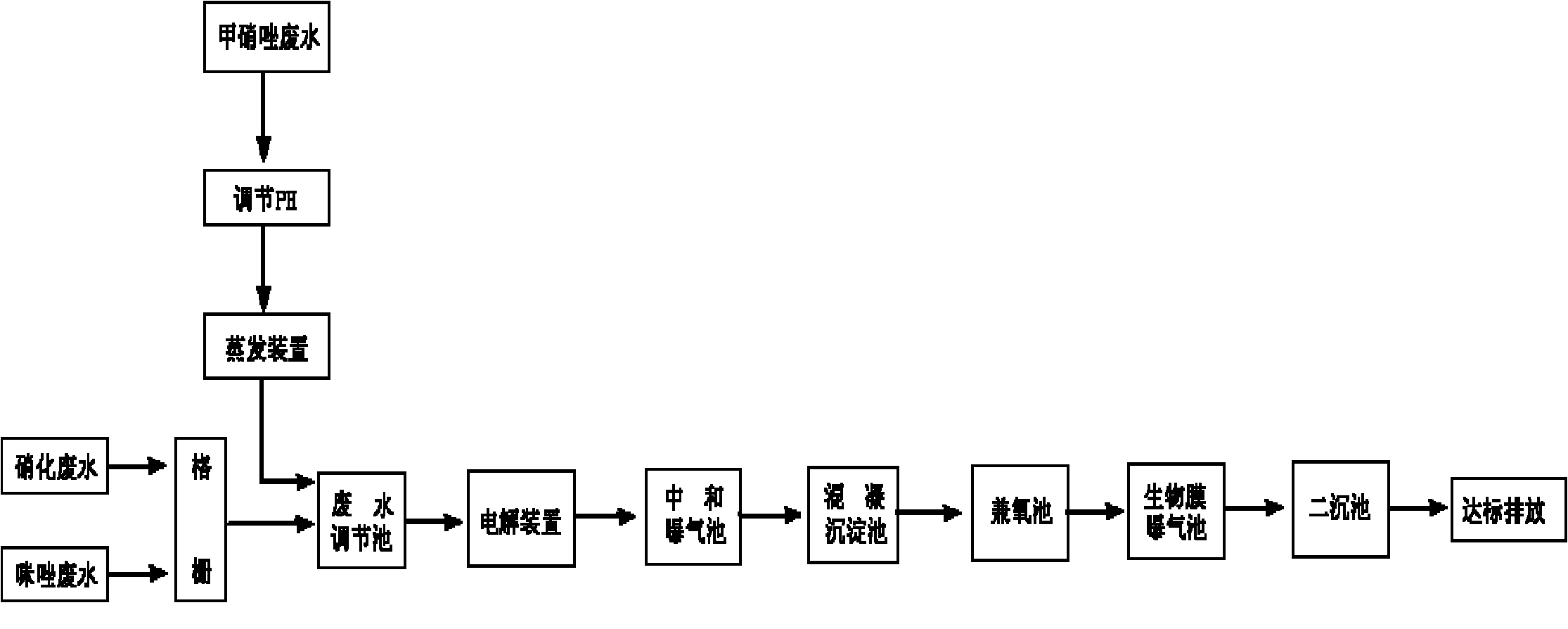

[0025] A kind of metronidazole production wastewater treatment method, its steps are as follows:

[0026] a. The wastewater from the metronidazole process is adjusted to pH 7.5-8.0 by adding alkali, and pumped into the evaporation device to remove salt, high boiling substances and residues, and then enter the wastewater adjustment tank;

[0027] b. The wastewater from the imidazole process and the nitrification process is separated through the grid, and the scum is removed, and then enters the wastewater regulating tank;

[0028] c. After being mixed in the wastewater regulating tank and adjusting the water quality and quantity, it is sent to the electrolysis device for electrochemical catalytic water treatment;

[0029] d. Add lime milk to the effluent of the electrolysis device to adjust the pH value to 8.5-9.0, then enter the neutralization aeration tank, and use an air compressor to blow air to remove ammonia-nitrogen;

[0030] e. After adding flocculant to the effluent o...

Embodiment 2

[0036] In the scheme described in Example 1, the electrochemical catalytic water treatment is two-stage electrolysis of a particle group electrochemical catalytic water treatment device and a pulse electrochemical catalytic water treatment device.

Embodiment 3

[0038] In the scheme described in Example 1, the evaporation is triple-effect evaporation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com