Quick-acting striking root leaf fertilizer

A foliar fertilizer, quick-acting technology, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of failure to achieve crop growth and development, inability to soak seeds and roots, and insignificant effects of increasing yields, so as to promote photosynthesis and The effect of stress resistance, high utilization rate, rapid greening and normal growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

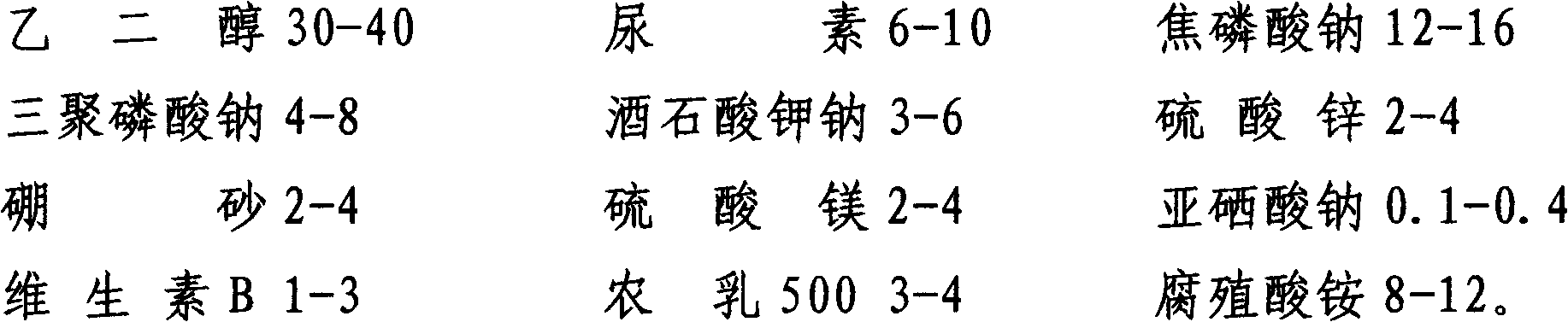

Method used

Image

Examples

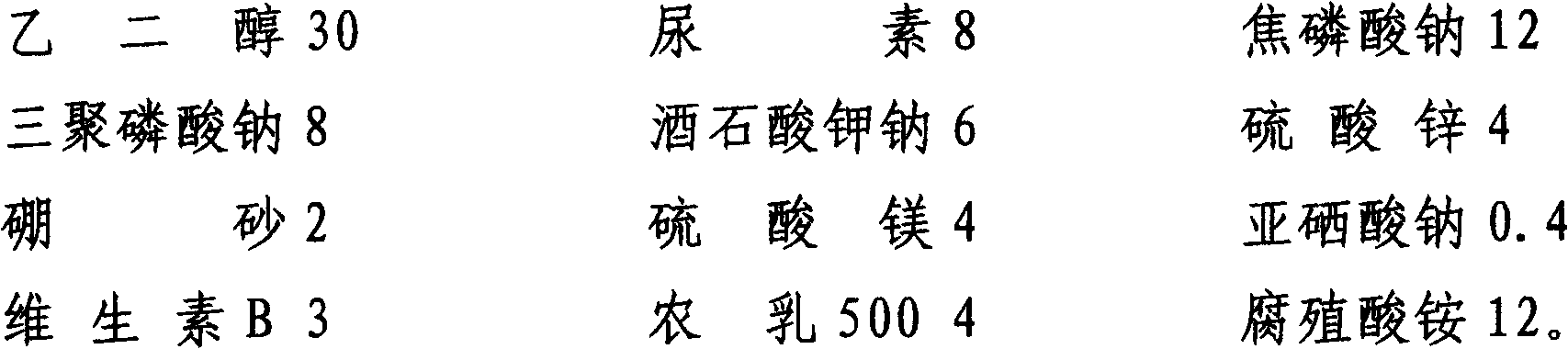

Embodiment 1

[0021] Take 30 parts of ethylene glycol, 8 parts of urea, 12 parts of sodium pyrophosphate, 8 parts of sodium tripolyphosphate, 6 parts of potassium sodium tartrate, 4 parts of zinc sulfate, 2 parts of borax, 4 parts of magnesium sulfate, selenous 0.4 parts of sodium phosphate, 3 parts of vitamin B, 5004 parts of agricultural milk, 12 parts of ammonium humate, set aside.

[0022] Under normal temperature and pressure, add water accounting for about 30% of the total mass of all raw materials in the reactor, then add the above-mentioned standby ethylene glycol and ammonium humate into the reactor, stir fully, and slowly heat up to 30 ℃ (± 5 ℃), then add the above-mentioned spare urea, potassium tripolyphosphate, sodium pyrophosphate, potassium sodium tartrate, zinc sulfate, borax, magnesium sulfate, sodium selenite respectively, and continue to heat up to 55 ℃ (± 5 ℃), after fully stirring and dissolving, start to cool down to room temperature, then add the above-mentioned spare...

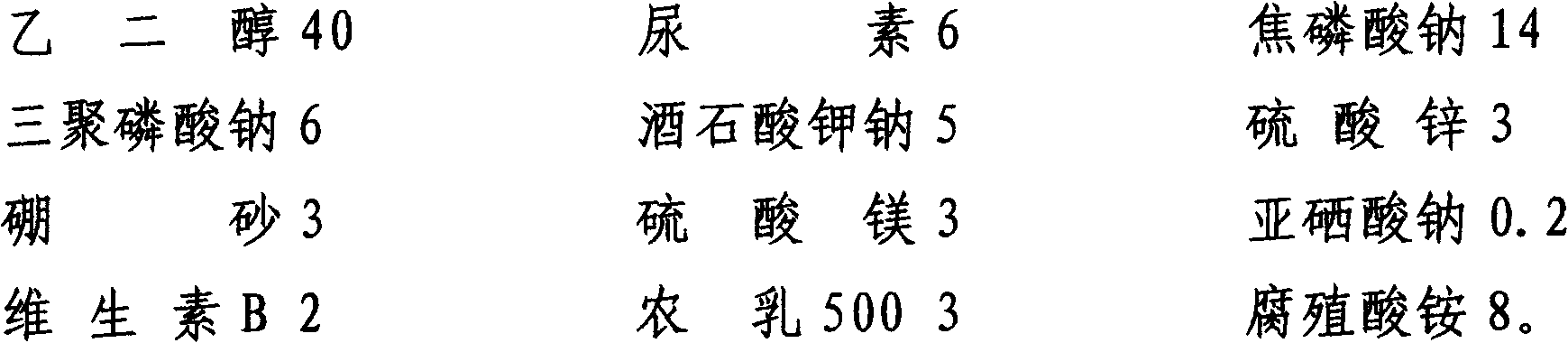

Embodiment 2

[0030] Take 40 parts of ethylene glycol, 6 parts of urea, 14 parts of sodium pyrophosphate, 6 parts of sodium tripolyphosphate, 5 parts of potassium sodium tartrate, 3 parts of zinc sulfate, 3 parts of borax, 3 parts of magnesium sulfate, selenous 0.2 parts of sodium phosphate, 2 parts of vitamin B, 3 parts of Nongru 500, 8 parts of ammonium humate, set aside.

[0031] Its preparation method and use method etc. are the same as embodiment one.

Embodiment 3

[0033] Take 38 parts of ethylene glycol, 10 parts of urea, 16 parts of sodium pyrophosphate, 4 parts of sodium tripolyphosphate, 3 parts of potassium sodium tartrate, 2 parts of zinc sulfate, 4 parts of borax, 2 parts of magnesium sulfate, selenous 0.1 part of sodium phosphate, 1 part of vitamin B, 3 parts of agricultural milk 500, 10 parts of ammonium humate, set aside.

[0034] Its preparation method and use method etc. are the same as embodiment one.

[0035] The quick-acting compound foliage fertilizer of the present invention can be widely used as a quick-acting greening foliage fertilizer for planting crops such as rice, tobacco, vegetables, melons and fruits.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com