Rectification method of allopurinol

A purification method and technology of allopurinol, applied in the field of chemical reaction purification, can solve the problems of low yield, large steam consumption, large amount of cooling water, etc., and achieve high product yield and purity, cheap and easy-to-obtain raw materials, and high yield. rate increase effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

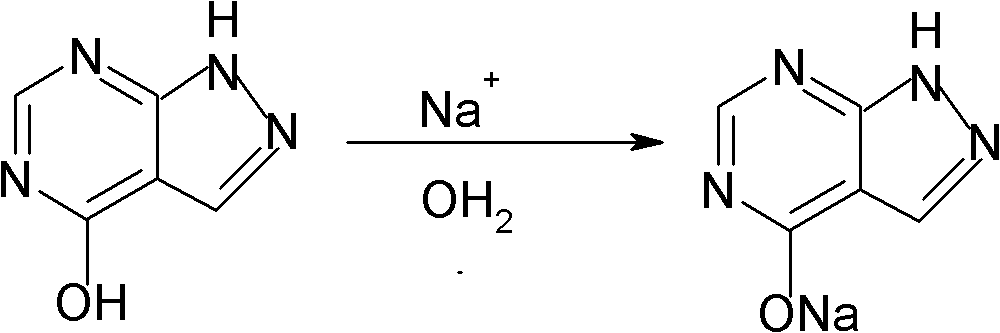

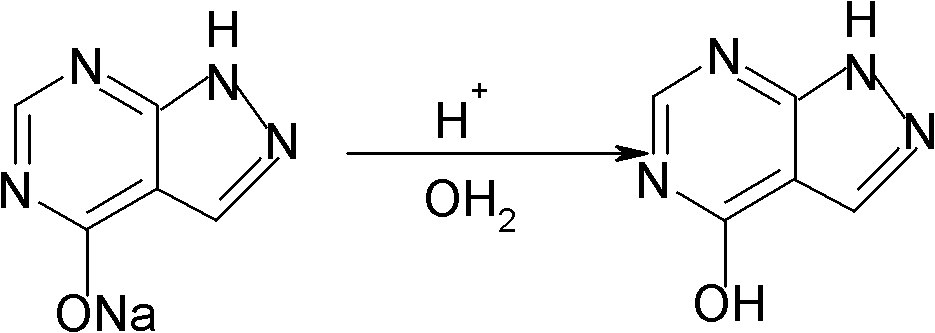

Image

Examples

Embodiment 1

[0021] (1) Alkaline dissolution: first add 10ml of purified water to a 100mL three-necked bottle, then add 5g (0.036mol) of crude allopurinol, start stirring, slowly add 65mL of 0.5mol / L NaOH solution, and control the pH to 6~7 until dissolved , a pale yellow liquid was obtained.

[0022] (2) Decolorization: add 0.5 g of activated carbon for needles, stir at 60° C. for 1 hour, and filter while hot.

[0023] (3) Acidification of the filtrate: prepare 66 mL (0.033 mol) of 0.5 mol / L HCl solution, put the filtrate in a 250 mL three-neck flask, add slowly while stirring, white objects will precipitate out, and keep the pH between 6 and 7. After the addition, continue to stir for 20 minutes and filter. The filter cake is washed 3 times with cold water and dried at 100° C. to obtain 4.1 g of off-white solid with a yield of 82%. Quality indicators: identification (color, UV, IR) in compliance with regulations; heavy metals ≤ 20ppm; residue on ignition ≤ 0.01%; HPLC product content 99...

Embodiment 2

[0025] (1) Alkaline dissolution: first add 15ml of purified water to a 250ml three-necked flask, then add 10g (0.0734mol) of crude allopurinol, in a 60°C water bath, start stirring, slowly add 73mL of 1.0mol / L NaOH solution, and control pH 6-7 until dissolved to obtain a light yellow liquid.

[0026] (2) Decolorization: add 0.8 g of activated carbon for needles, stir at 60° C. for 1 hour, and filter while hot.

[0027] (3) Filtration: prepare 74mL (0.074mol) of 1mol / L HCl solution, put the filtrate in a 250mL three-neck flask, add it under stirring, white objects will precipitate out, and keep the pH between 6 and 7. After the addition, continue to stir for 30 minutes and filter. The filter cake is washed twice with cold water and dried at 90° C. to obtain 8.0 g of off-white color. Yield 80%. Quality indicators: identification (color, UV, IR) in compliance with regulations; heavy metals ≤ 20ppm; residue on ignition ≤ 0.04%; HPLC product content 99.2%; related substances: sin...

Embodiment 3

[0029] (1) Alkaline dissolution: first add 20ml of purified water to a 250ml three-necked bottle, then add 10g (0.0734mol) of crude allopurinol, put it in a water bath at 60°C, start stirring, and slowly drop in 41mL of 1.5mol / L NaOH solution, Control the pH to 6-7 until dissolved to obtain a light yellow liquid.

[0030] (2) Decolorization: Add 0.5 g of activated carbon for needles, stir at 60° C. for 1 h, and filter.

[0031] (3) Filtration: Put the filtrate in a 250ml three-neck flask, start stirring, add 40mL (0.06mol) of 1.5mol / L HCl solution, white objects will precipitate out, and keep the pH between 6 and 7. After the addition, continue to stir for 40 minutes to filter, wash the filter cake 3 times with water, and dry at 80°C to obtain 8.1 g of off-white (a little light yellow) substance. Yield 81%. Quality indicators: identification (color, UV, IR) in compliance with regulations; heavy metals: ≤20ppm; residue on ignition: ≤0.04%; content HPLC: 98.2%; related substan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com