Anti-seepage leak-stopping epoxy adhesive and preparation method thereof

A leaky epoxy adhesive and coupling agent technology, applied in the direction of adhesives, epoxy resin adhesives, adhesive types, etc., can solve the problems of high brittleness of the adhesive layer, low bonding strength, poor fatigue resistance, etc. Improved toughness, low cost, good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

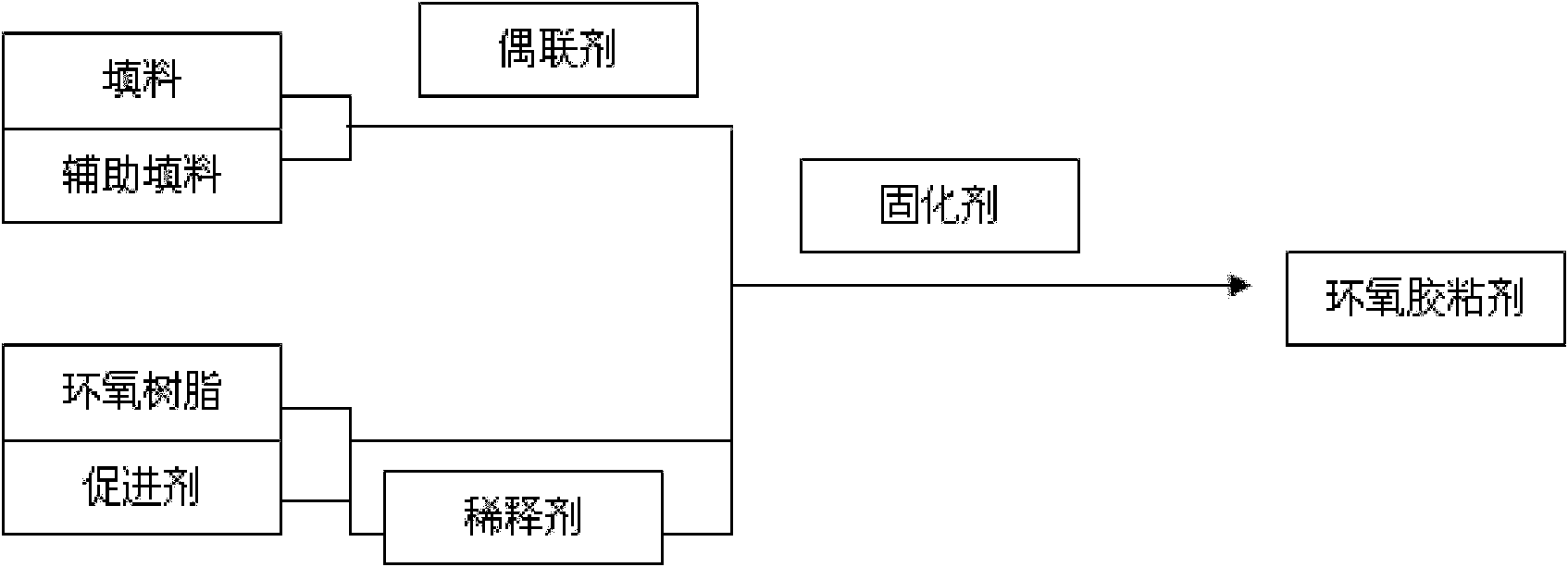

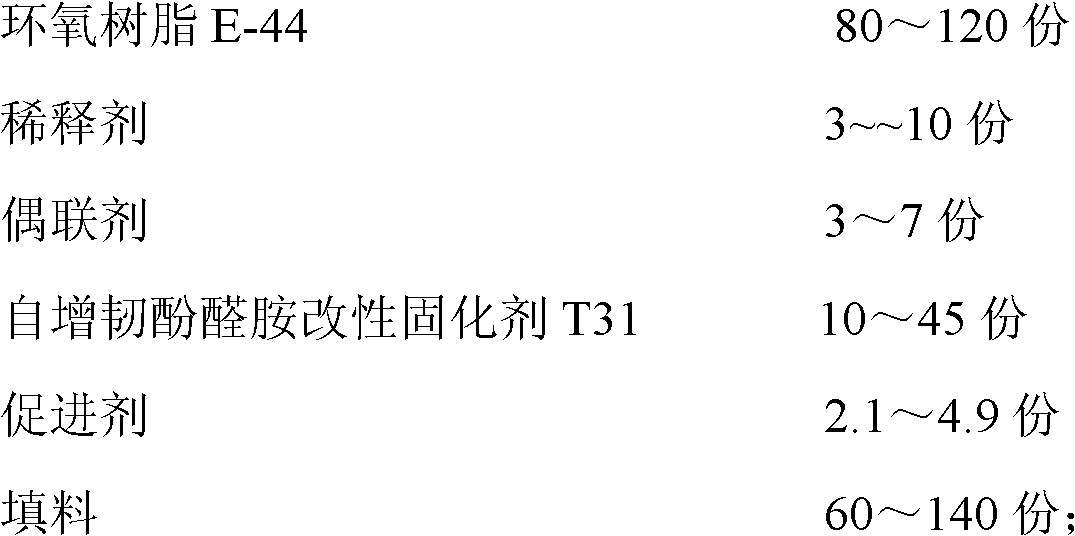

Method used

Image

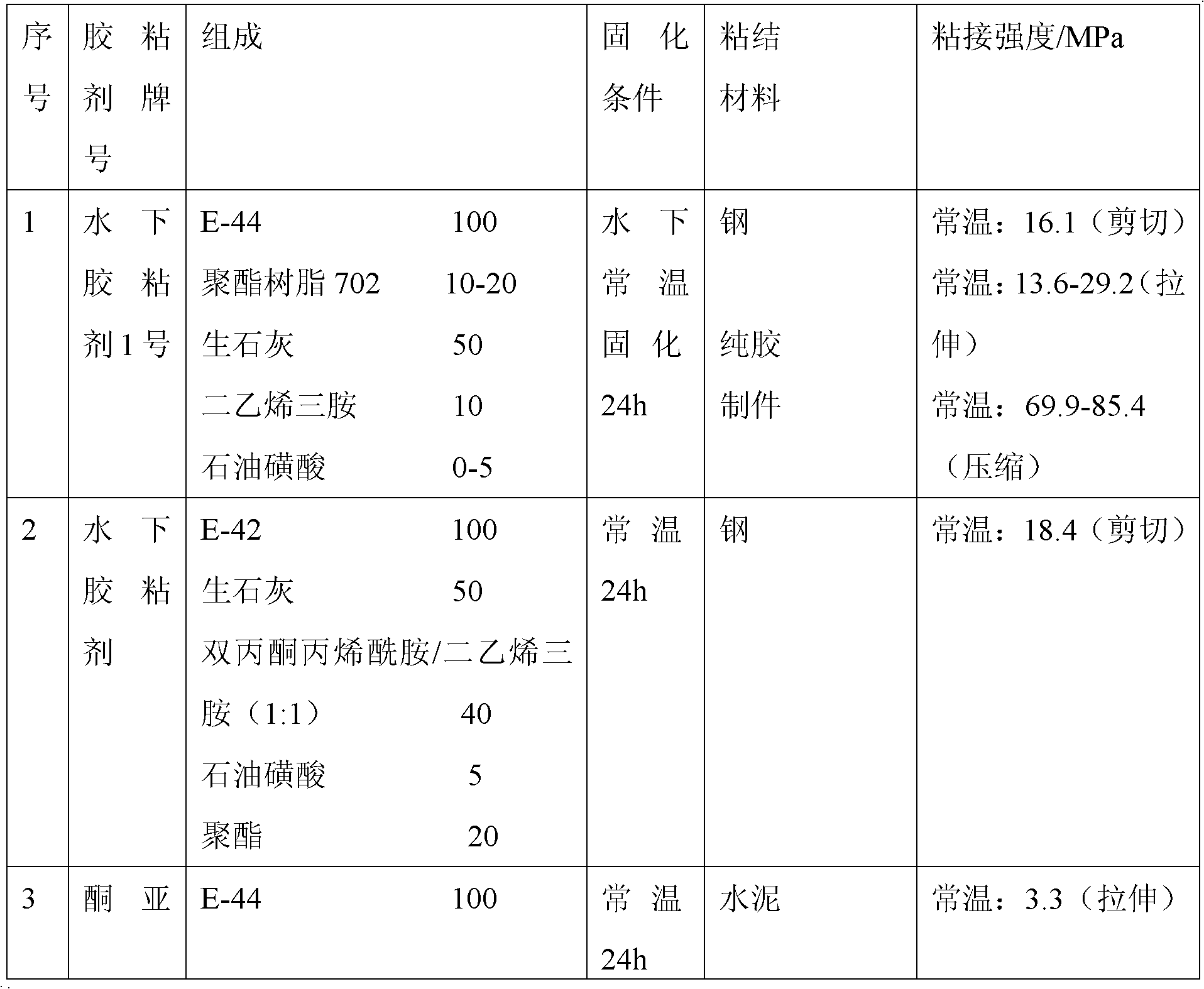

Examples

Embodiment 1

[0028] Component A: Take 120 parts of cement dried at 50°C for 5 hours and 10 parts of auxiliary filler calcium oxide, add 5 parts of KH560, stir for 5 minutes, mix evenly, and set aside. B component: Take 100 parts of epoxy resin E-44, add 10 parts of diluent, 2.8 parts of accelerator diethylene triamine, stir for 5 minutes, and mix well. Add component A to component B, stir for 5 minutes, mix well, then add 30 parts of self-toughening phenalkamine modified curing agent T31, stir well, and measure its performance. The metal-to-metal shear strength was tested using the national standard, and it was cured at room temperature for 24 hours, and its shear strength reached about 21.91MPa.

Embodiment 2

[0030] Component A: Take 100 parts of cement dried at 50°C for 5 hours and 10 parts of calcium oxide as an auxiliary filler, add 5 parts of Nanda One, stir for 5 minutes, mix well, and set aside. Part B: Take 100 parts of epoxy resin E-44, add 10 parts of diluent, 2.8 parts of accelerator triethylenetetramine, stir for 5 minutes, and mix well. Add component A to component B, stir for 5 minutes, mix well, then add 40 parts of self-toughening phenalkamine modified curing agent T31, stir well, and measure its performance. The national standard is used to test the shear strength of its metal to metal, and it is cured at room temperature for 24 hours, and its shear strength reaches about 15.22MPa.

Embodiment 3

[0032] Component A: Take 120 parts of cement dried at 50°C for 5 hours and 10 parts of calcium oxide as auxiliary filler, add 4 parts of KH560, 5 parts of petroleum sulfonic acid, stir for 5 minutes, mix well, and set aside. B component: Take 100 parts of epoxy resin E-44, add 10 parts of diluent, 2.8 parts of accelerator tetraethylenepentamine, stir for 5 minutes, and mix well. Add component A to component B, stir for 5 minutes, mix well, then add 40 parts of self-toughening phenalkamine modified curing agent T31, stir well, and measure its performance. The national standard is used to test the metal-to-metal shear strength. After the dry glue is cured at room temperature for 24 hours, the shear strength reaches about 17.00MPa, and the adhesive strength when the dry glue is cured in water is 19.3MPa; when the wet glue is cured in water, The bonding strength is 6.8MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shear strength | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com