Phosphor, light emitting device and white light emitting diode

A light-emitting diode and white light-emitting technology, which is applied to the use of light-emitting materials, semiconductor devices, and gas discharge lamps, and can solve problems such as the reduction of luminous intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

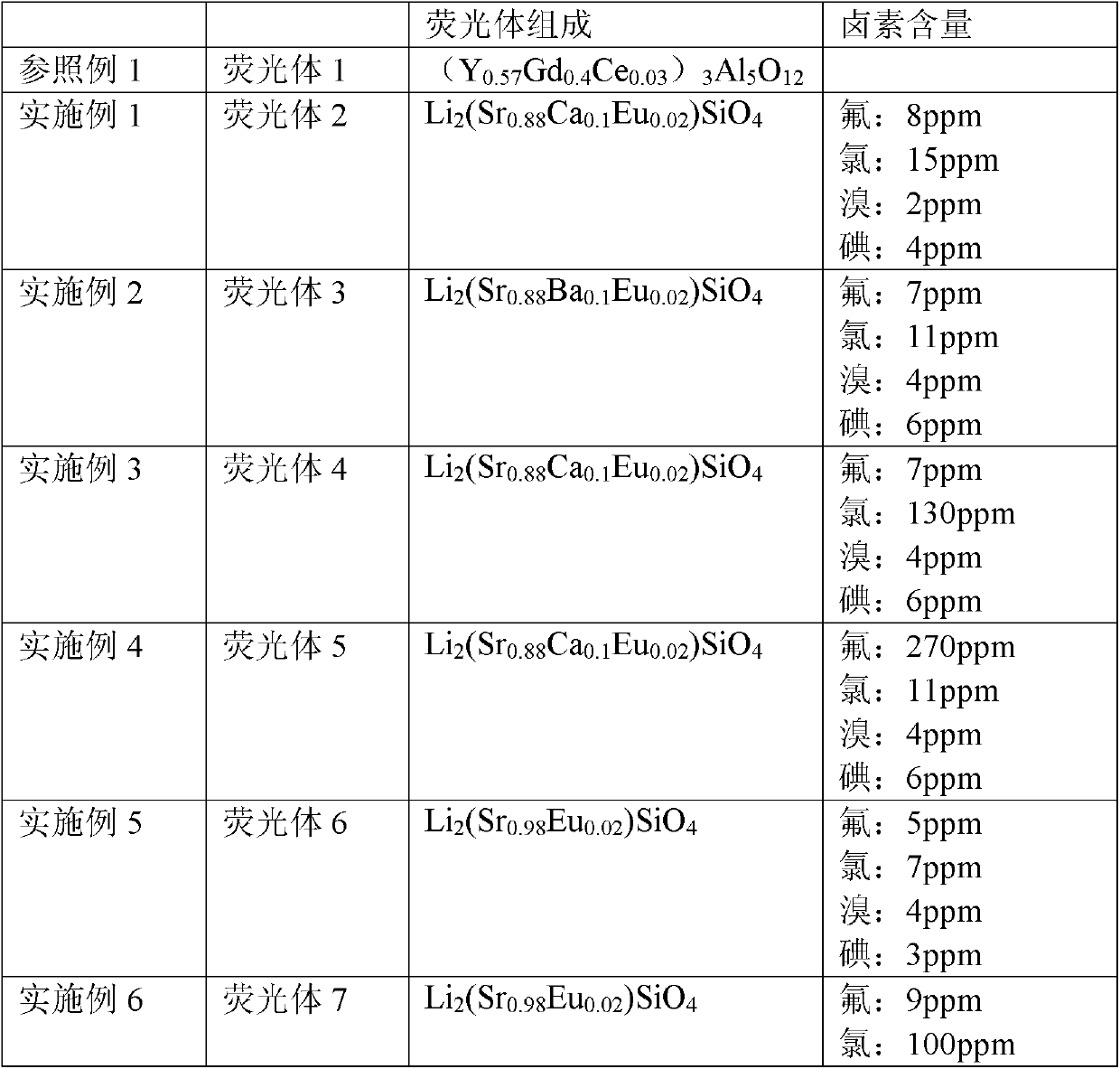

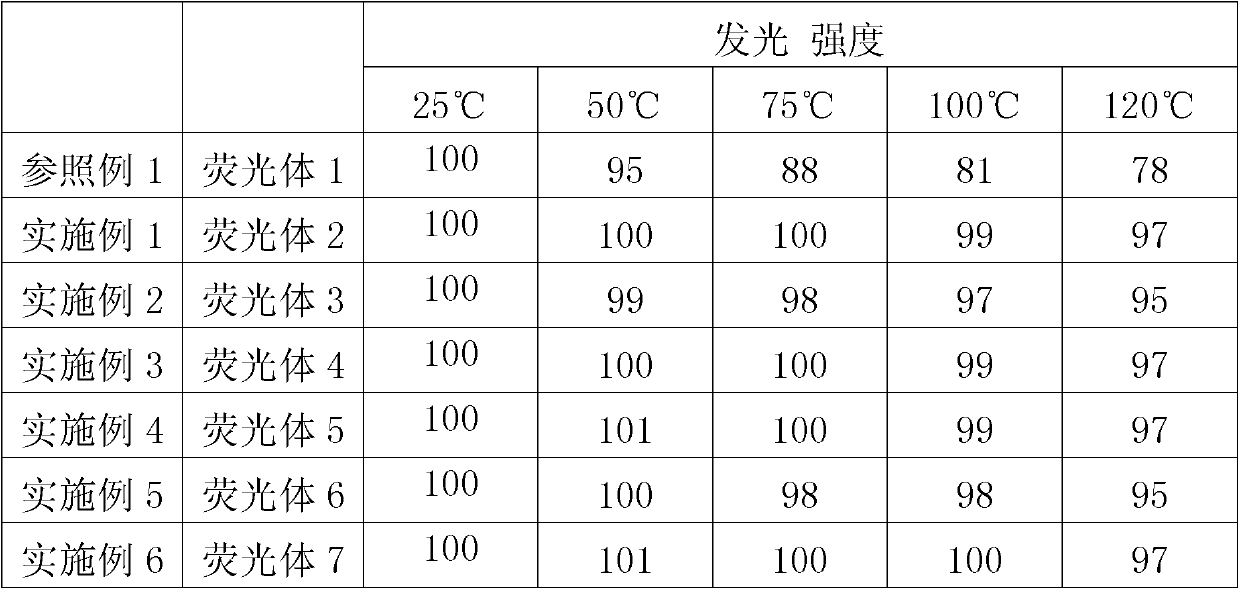

[0082] Lithium carbonate (manufactured by Kanto Chemical Co., Ltd., purity 99%), strontium carbonate (Sakai Chemical Industry Co., Ltd. Manufactured, purity 99% or more), calcium carbonate (manufactured by Ube Materials Co., Ltd., purity 99.9%), europium oxide (manufactured by Shin-Etsu Chemical Co., Ltd., purity 99.99%), silicon dioxide (manufactured by Nippon Aerosil Co., Ltd., purity 99.99%) ), a total of 10 parts by weight of these materials and 150 parts by weight of isopropanol were added in the wet ball mill, and mixed for 4 hours to obtain a slurry. After drying the slurry with an evaporator at 70°C, the resulting metal compound mixture was fired at 900°C for 12 hours in the air, and then slowly cooled (cooling rate 5°C / min) to room temperature (25°C). . Next, after crushing with an agate mortar, the 2 N 2 Firing was carried out at 900° C. for 12 hours in an atmosphere, and then slowly cooled to room temperature (cooling rate: 5° C. / minute), whereby phosphor 2 was o...

Embodiment 2

[0084] Lithium carbonate (manufactured by Kanto Chemical Co., Ltd., purity 99%), strontium carbonate (Sakai Chemical Industry Co., Ltd. Manufactured, purity 99% or more), barium carbonate (Nippon Chemical Industry Co., Ltd., purity 99% or more), europium oxide (manufactured by Shin-Etsu Chemical Co., Ltd., purity 99.99%), silicon dioxide (manufactured by Nippon Aerosil Co., Ltd., purity 99.99%) %) as a raw material, the same operation as in Example 1 was performed to obtain phosphor 3 . Table 1 shows the composition of the phosphor 3, and Table 2 shows the measurement results of the emission intensity.

Embodiment 3

[0086] Lithium carbonate (manufactured by Kanto Chemical Co., Ltd., purity 99%), strontium carbonate (Sakai Chemical Industry Co., Ltd., purity 99% or more), calcium carbonate (Ube Material Co., Ltd., purity 99.9%), europium oxide (Shin-Etsu Chemical Co., Ltd., purity 99.99%), silicon dioxide (Nippon Aerosil Co., Ltd. , purity 99.99%), ammonium chloride (manufactured by Wako Pure Chemical Industries, Ltd., purity 99%), a total of 10 parts by weight of these compounds and 150 parts by weight of isopropanol were added to a wet ball mill and mixed for 4 hours to obtain The slurry. After drying the slurry at 70° C. with an evaporator, the obtained metal compound mixture was fired at 900° C. for 12 hours in an air atmosphere, and then gradually cooled to room temperature. Next, after crushing with an agate mortar, the 2 N 2 After baking at 900° C. for 12 hours in an atmosphere, the phosphor was gradually cooled to room temperature, and Phosphor 4 was obtained. Table 1 shows the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com