Atomizer and emission analyzer

An atomizer and plasma technology, used in thermal excitation analysis, material excitation analysis, plasma, etc., can solve the problems of voltage time delay, poor atomization efficiency, low luminous intensity, etc., to improve accuracy, suppress dispersion, The effect of increased luminous intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

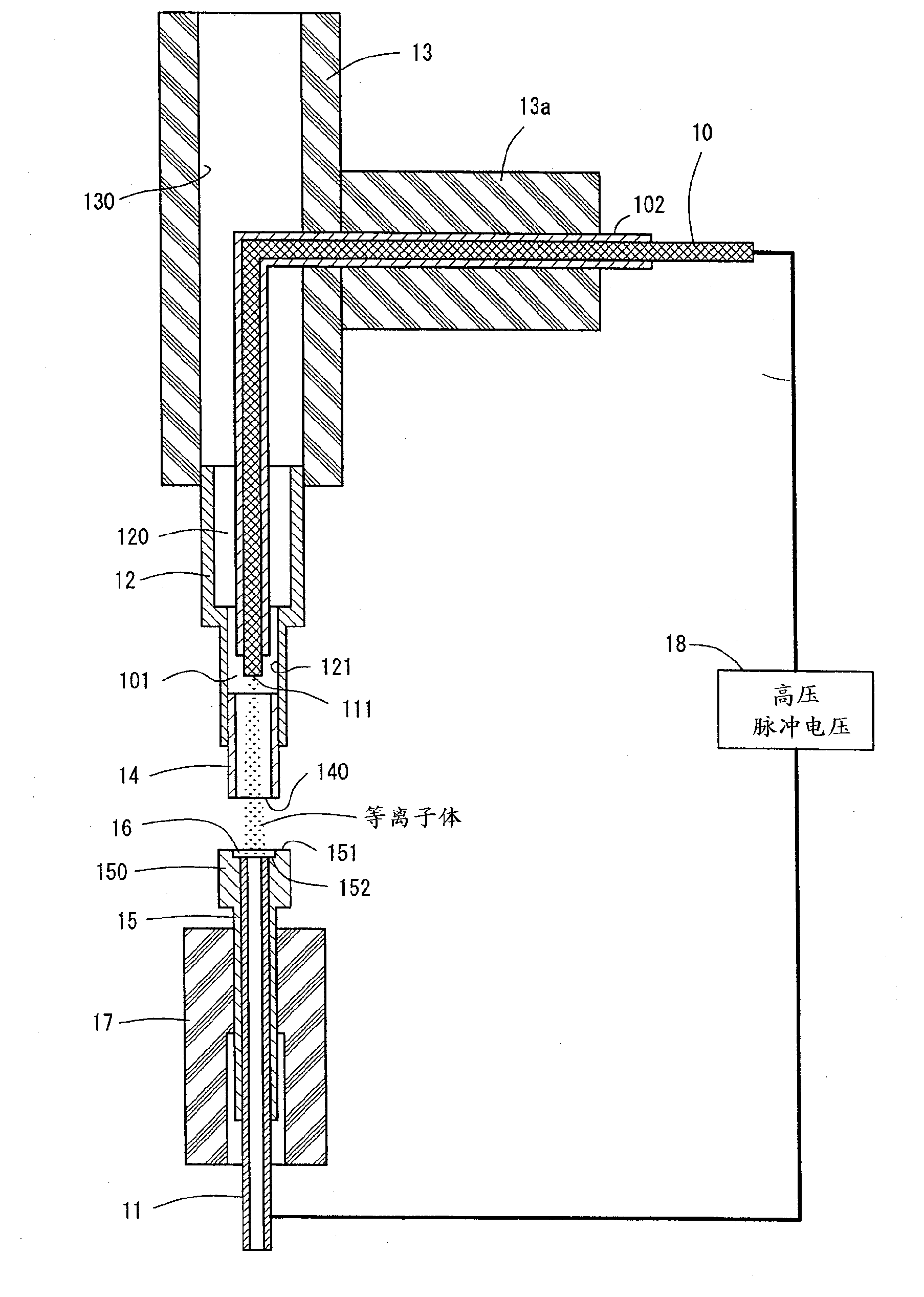

[0042] figure 1 It is a figure showing the structure of the atomizer of Example 1. The atomizer of Example 1 has a rod electrode 10 (the first electrode of the present invention) and a sample electrode 11 (the second electrode of the present invention). The rod-shaped electrode 10 has a rod-shaped structure made of Cu with a diameter of 1.2 mm, and the sample electrode 11 has a tubular structure made of stainless steel with an outer diameter of 2 mm and an inner diameter of 1 mm. The outer peripheral surface of the rod electrode 10 is covered with an insulator 102 .

[0043] For the rod electrode 10, stainless steel, molybdenum, tungsten, etc. can be used other than Cu. In addition, Cu, molybdenum, tungsten, etc. can be used for the sample electrode 11 other than stainless steel. However, in consideration of the problem that the sample electrode 11 itself will be atomized to affect the analysis, it is necessary to use a material that does not contain the target element for ...

Embodiment 2

[0061] Next, Example 2 will be described. Figure 8 It is a figure which shows the structure of the atomizer of Example 2. The atomizer of Example 2 has a rod electrode 10 (the first electrode of the present invention) and a sample electrode 11 (the second electrode of the present invention). The rod-shaped electrode 10 is a rod made of Cu with a diameter of 1.2 mm, and the sample electrode 11 is a tube made of stainless steel with an outer diameter of 2 mm and an inner diameter of 1 mm.

[0062] For the rod electrode 10 , other than Cu, stainless steel, molybdenum, tungsten, or the like can be used. In addition, Cu, molybdenum, tungsten, etc. can be used for the sample electrode 11 other than stainless steel. However, in consideration of the problem that the sample electrode 11 itself will be atomized to affect the analysis, it is necessary to use a material that does not contain the target element for the sample electrode 11, or perform coating, electroplating, etc. with a...

experiment example 1

[0073] Figure 11 It is a graph showing the results of measuring the light-receiving angle dependence of the emission intensity of the atmospheric-pressure plasma obtained by the atomizer of Example 2. The horizontal axis represents the light receiving angle, and the light receiving angle is the angle formed by the straight line connecting the sample and the light receiving device and the plane perpendicular to the opposing direction (axial direction) of the rod electrode 10 and the sample electrode 11 . The light receiving device is an optical fiber provided with a lens at the end, and the optical fiber is connected with the light splitting device. The sample is water containing 1ppm of Cu, and the luminous intensity of Cu at the resonance line spectral wavelength (324.75nm) is measured by a light receiving device. In addition, the distance between the rod electrode 10 and the sample electrode 11 was 4 mm, and the distance from the sample to the light receiving device was 4 mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com