Production method of wild kiwi fruit wine

A production method and technology of kiwifruit, applied in the field of fruit processing, can solve the problems of affecting the flavor characteristics of kiwifruit wine, losing the significance of health care, and poor economic benefits, etc., and achieve the simple and feasible brewing process, simple and easy clarification process, and reduce bitterness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

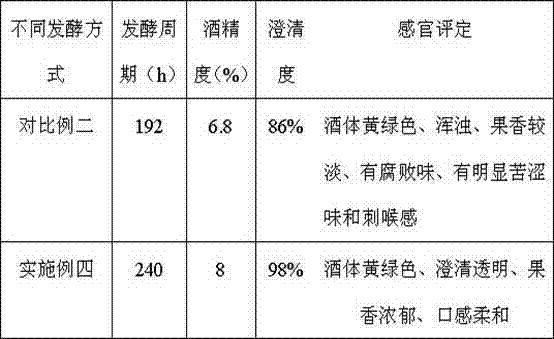

Examples

Embodiment 1

[0015] Wash and crush the mature wild kiwifruit, add 60mg / kg of sulfur dioxide and 0.2mL / kg of low-temperature pulp enzyme, mix well, place it at 20°C for 1.5 hours and then squeeze it. The juice yield is 0.804mL / g. Add 1% gelatin solution at 0.5g / L to clarify for 10 hours, and centrifuge to obtain clarified juice with a clarity of more than 95%. The juice is emerald green in color, rich in aroma, and the preservation rate of Vc reaches 72%.

Embodiment 2

[0017] Wash and crush the mature wild kiwifruit, add 90mg / kg of sulfur dioxide and 0.4mL / kg of low-temperature pulp enzyme, mix well, put it at 20°C for 2.5 hours and then squeeze it. The juice yield is 0.84mL / g, and pour it into the squeezed juice Add 1% gelatin solution at an amount of 0.5g / L to clarify for 10 hours, and centrifuge to obtain clarified juice with a clarity of more than 95%. The juice is emerald green in color, rich in aroma, and the preservation rate of Vc reaches 69%.

Embodiment 3

[0019] Wash and crush the mature wild kiwifruit, add 60mg / kg of sulfur dioxide and 0.4mL / kg of low-temperature pulp enzyme, mix well, place it at 25°C for 2 hours and then squeeze it. The juice yield is 0.834mL / g, and pour it into the squeezed juice Add 1% gelatin solution at 0.5g / L to clarify for 10 hours, and centrifuge to obtain clarified juice with a clarity of more than 95%. The juice is emerald green in color, rich in aroma, and the preservation rate of Vc reaches 67%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com