Rubrene weak epitaxial growth thin film and application thereof in organic thin-film transistor

A weak epitaxial growth, rubrene technology, applied in the direction of crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of complex process, poor quality of polycrystalline film, etc., to achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

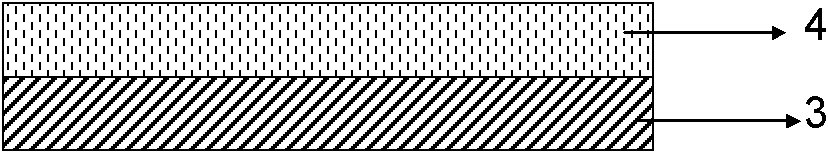

[0074] The preparation method of rubrene weak epitaxial growth film involved in the present invention is as follows

[0075] (1) A layer of SiO is formed by thermal growth on the surface 2 The heavily doped silicon wafer surface vacuum deposition induction layer 3; The material of the induction layer 3 is: hexabiphenyl (p-6P), 2,7-two (4-biphenyl)-phenanthrene (BPPh), 2,7-bis(4-biphenyl)-thiofluorene (BPBTB), 2,6-bis(4-biphenyl)-benzo[1,2-b:4,5-b']dithiophene (BPTBT), 2,5-bis(4-biphenyl)-[3,2-b]dithiophene (BPTT), 5,5'-bis(4-biphenyl)-2,2'- Dithiophene (BP2T), 5,5″-bis(4-biphenyl)-2,2′:5′,2″-trithiophene (BP3T), 5,5″′-bis(4-biphenyl) )-2, 2': 5', 2": 5", 2"'-tetrathiophene (BP4T), 1, 1': 4', 1": 4", 1"': 4"', 1" ″: 4″″, 1″″′: 4″″′, 1″″″: 4″″″, 1″″″′-octyl (p8P), 2,5-di(4-1,1 ': 4', 1"-terphenyl)-thiophene (3PT), 5,5'-di(4-1,1': 4', 1"-terphenyl)-2,2'-dithiophene (3P2T), 2,5-bis(4-1,1′:4′,1″-terphenyl)-[3,2-b]dithiophene (3PTT), 2,7-bis(4- 4′-fluorobiphenyl)-phenanthrene ...

Embodiment 2

[0089] The first kind of structure that the present invention relates to adopts the transistor of rubrene weak epitaxial growth film, such as Figure 6 As shown, the preparation method is as follows:

[0090] (1) A layer of SiO is formed by thermal growth on the surface 2 The heavily doped silicon wafer surface vacuum-deposits induction layer 3, and the material of described induction layer 3 is the same as embodiment 1, and thickness is not less than 2 nanometers, is not more than 12 nanometers; Described heavily doped silicon is used as transistor gate electrode, SiO 2 as the insulated gate of the transistor;

[0091] (2) Vacuum-deposit rubrene film 4 on the surface of induction layer 3, the thickness of said rubrene film 4 is not less than 5 nanometers, not more than 50 nanometers;

[0092] (3) On the surface of the rubrene film 4, a metal gold electrode 6 is vacuum-deposited by a leak mask method;

[0093] Among them, the background vacuum degree is not lower than 1×10 ...

Embodiment 3

[0100] The device configuration of the transistor with the second structure that uses rubrene weakly epitaxially grown thin film is as follows Figure 8 As shown, the specific preparation method is as follows:

[0101] (1) A layer of SiO is formed by thermal growth on the surface 2 The heavily doped silicon wafer surface vacuum-deposits induction layer 3, and the material of described induction layer 3 is the same as embodiment 1, and thickness is not less than 2 nanometers, is not more than 12 nanometers; Described heavily doped silicon is used as transistor gate electrode, SiO 2 as the insulated gate of the transistor;

[0102] (2) On the surface of the induction layer 3, a metal gold electrode 6 is vacuum-deposited by a leak mask method;

[0103] (3) Vacuum-deposit a rubrene film 4 on the surface of the induction layer 3, the thickness of the rubrene film 4 is not less than 5 nanometers, not more than 50 nanometers;

[0104] Among them, the background vacuum degree is no...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com