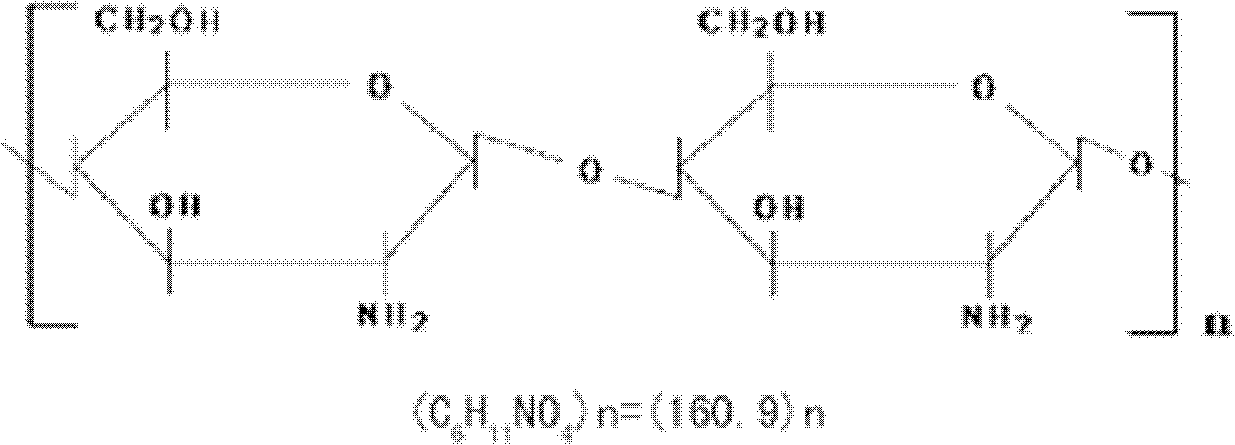

Method for dyeing chitosan fabrics with reactive dyes

A technology of reactive dyes and chitosan, applied in the field of textile dyeing and finishing, can solve the problem of high loss of chitosan content, and achieve the effects of less loss of chitosan content, reduced loss of chitosan and good levelness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] The chitosan lining used in the present embodiment is the single jersey fabric containing chitosan 11.4wt%, Newdal (Newdal) 57wt%, combed cotton 26.6wt% and 5wt% Lycra (LYCRA); Used chitosan The weight of the fabric is 30kg, and the reactive dye used is a nicotinic acid-s-triazine reactive dye. In this embodiment, chitosan fabrics are dyed into water green with reactive dyes.

[0064] In the present embodiment, the used raw materials and consumption of each operation, specific steps and parameters are as follows:

[0065] a) Oxygen bleaching process: place the chitosan fabric in an oxygen bleaching solution with a pH value of 10, with a bath ratio of 1:15, keep it warm for 60 minutes at a temperature of 85°C, and then cool down to below 60°C to discharge the oxygen bleaching solution , washing the chitosan fabric until the pH value of the residual liquid is 7.2; the oxygen bleaching solution contains scouring agent DHA-150, softener Yuzhongbao C, sodium hydroxide, 27% ...

Embodiment 2

[0071] The used chitosan lining of the present embodiment is to contain chitosan 9.5wt%, modal (Modal) 57wt%, combed cotton 28.5wt% and 5wt% Lycra semi-pearl mesh cloth fabric; Used chitosan fabric weight is 30kg; the reactive dye used is bis-nicotinic acid-s-triazine reactive dye. In this embodiment, chitosan fabrics are dyed light purple with reactive dyes.

[0072] In the present embodiment, the used raw materials and consumption of each operation, specific steps and parameters are as follows:

[0073] a) Oxygen bleaching process: place the chitosan fabric in an oxygen bleaching solution with a pH value of 13.5, with a bath ratio of 1:15, at a temperature of 98°C, keep warm for 30 minutes, and then cool down to below 60°C to discharge the oxygen bleaching solution , wash the chitosan fabric until the pH value of the residual liquid is 8.3; the oxygen bleaching solution contains scouring agent THR-203, softener FB-200, sodium hydroxide, 27% hydrogen peroxide, hydrogen perox...

Embodiment 3

[0079] The chitosan fabric used in the present embodiment is the double-sided fabric fabric containing chitosan 11.8wt%, hemp Saier (Jutecell) 48wt%, combed cotton 35.2wt% and 5wt% Lycra; Used chitosan fabric weight It is 30kg; the reactive dye used is a nicotinic acid-s-triazine reactive dye. In this embodiment, the chitosan fabric is dyed into washing blue with reactive dyes.

[0080] In the present embodiment, the used raw materials and consumption of each operation, specific steps and parameters are as follows:

[0081] a) Oxygen bleaching process: place the chitosan fabric in an oxygen bleaching solution with a pH value of 12, the liquor ratio is 1:15, keep the temperature at 90°C for 45 minutes, then cool down to below 60°C to discharge the oxygen bleaching solution , washing the chitosan fabric until the pH value of the residual liquid is 7.6; the oxygen bleaching solution contains scouring agent C-320, softener ES, sodium hydroxide, 27% hydrogen peroxide, hydrogen per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com